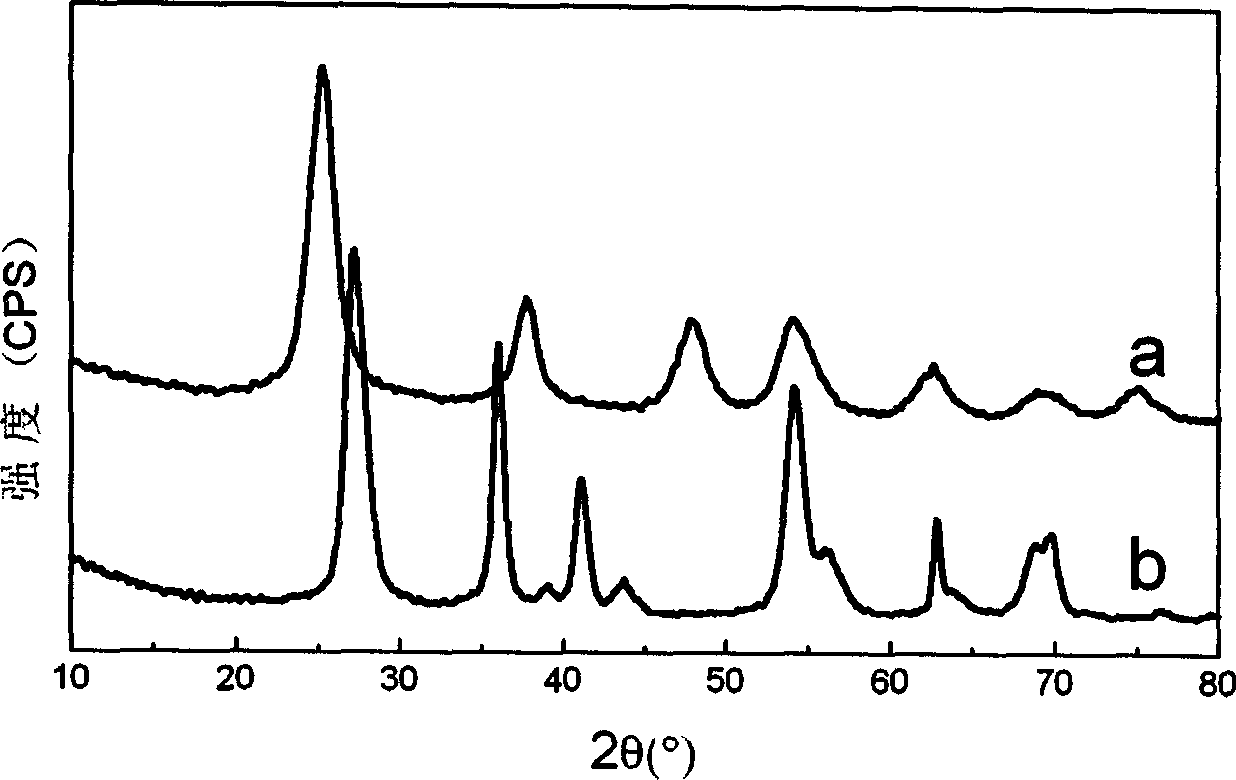

Method for preparing carbon and nitrogen-doped titanium dioxide photocatalyst

A technology of titanium dioxide and catalyst, which is applied in the field of preparation of titanium dioxide photocatalyst, which can solve the problems of increasing grain size, difficulty in ensuring the stability and uniformity of photocatalyst structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the titanium dioxide visible light catalyst doped with carbon and nitrogen of the present invention comprises the following steps:

[0015] (1) Surfactant Triton X-100 (Triton X-100), co-surfactant n-hexanol and continuous oil phase cyclohexane are mixed, stirred to a transparent solution as the oil phase; n-butyl titanate and Nitric acid or hydrochloric acid is mixed to form a water phase, and the water phase is added dropwise into the oil phase under stirring conditions to form a transparent microemulsion;

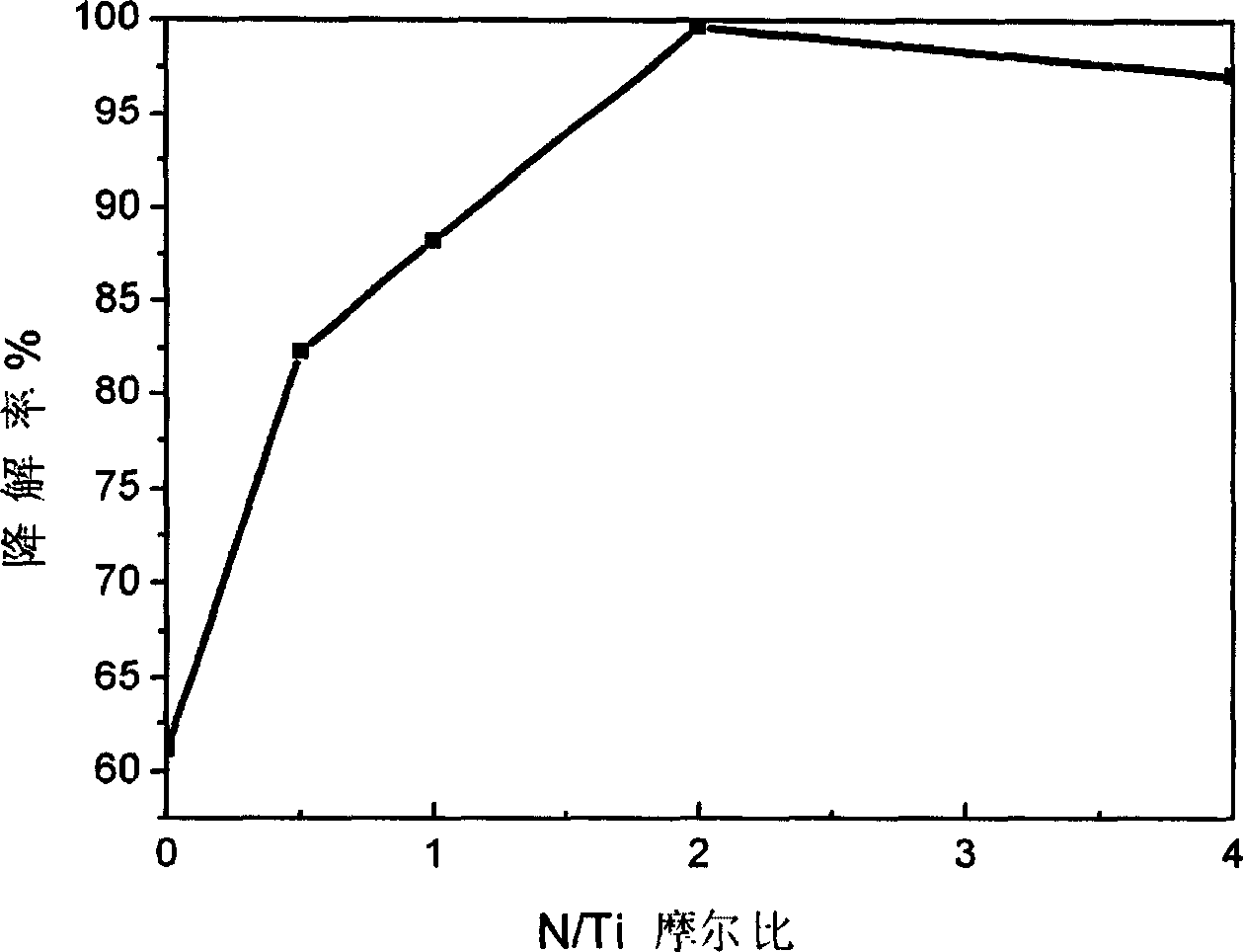

[0016] (2) nitrogen source (such as: triethylamine, urea, thiourea or N 2 h 4 ·H 2 O) add in the microemulsion obtained by step (1), make the molar ratio of N and Ti be 0.5~4, get transparent solution after stirring;

[0017] (3) Place the solution obtained from step (2) in a reactor, and conduct a hydrothermal reaction at 120°C for 13 hours; wash the solid product of the hydrothermal reaction with absolute ethanol and distilled water,...

Embodiment 1

[0025] Mix 10ml Triton X-100, 6ml n-hexanol and 16ml cyclohexane, stir until the solution is transparent, add the mixed solution of 3.4ml n-butyl titanate and 8ml 5M nitric acid dropwise into the above solution to form a transparent microemulsion, continue Stir for 6h. The resulting mixed solution was transferred to a 100 mL stainless steel autoclave lined with polytetrafluoroethylene, and hydrothermally heated at 120 °C for 13 h. After hydroheating, the upper layer in the kettle is a transparent yellow liquid, and the lower layer is a milky white solid. The upper layer liquid in the kettle is poured out, and the solid product obtained is washed three times with absolute ethanol and distilled water, and dried at 100 ° C after centrifugation. A milky white powder was obtained.

Embodiment 2

[0027] Except that the 5M nitric acid of 8ml among the 10M hydrochloric acid of 4ml is replaced in embodiment 1, other conditions are the same as embodiment 1 to white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com