Method for preparing nano metal pipe by template chemical plating process

A nano-metal and electroless plating technology, which is applied in the field of template electroless plating to prepare nano-metal tubes, can solve the problems of difficult control of the size and shape of nano-metal tubes, low output, complex process, etc., and achieve good controllability and batch production The effect of preparation feasibility, high yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

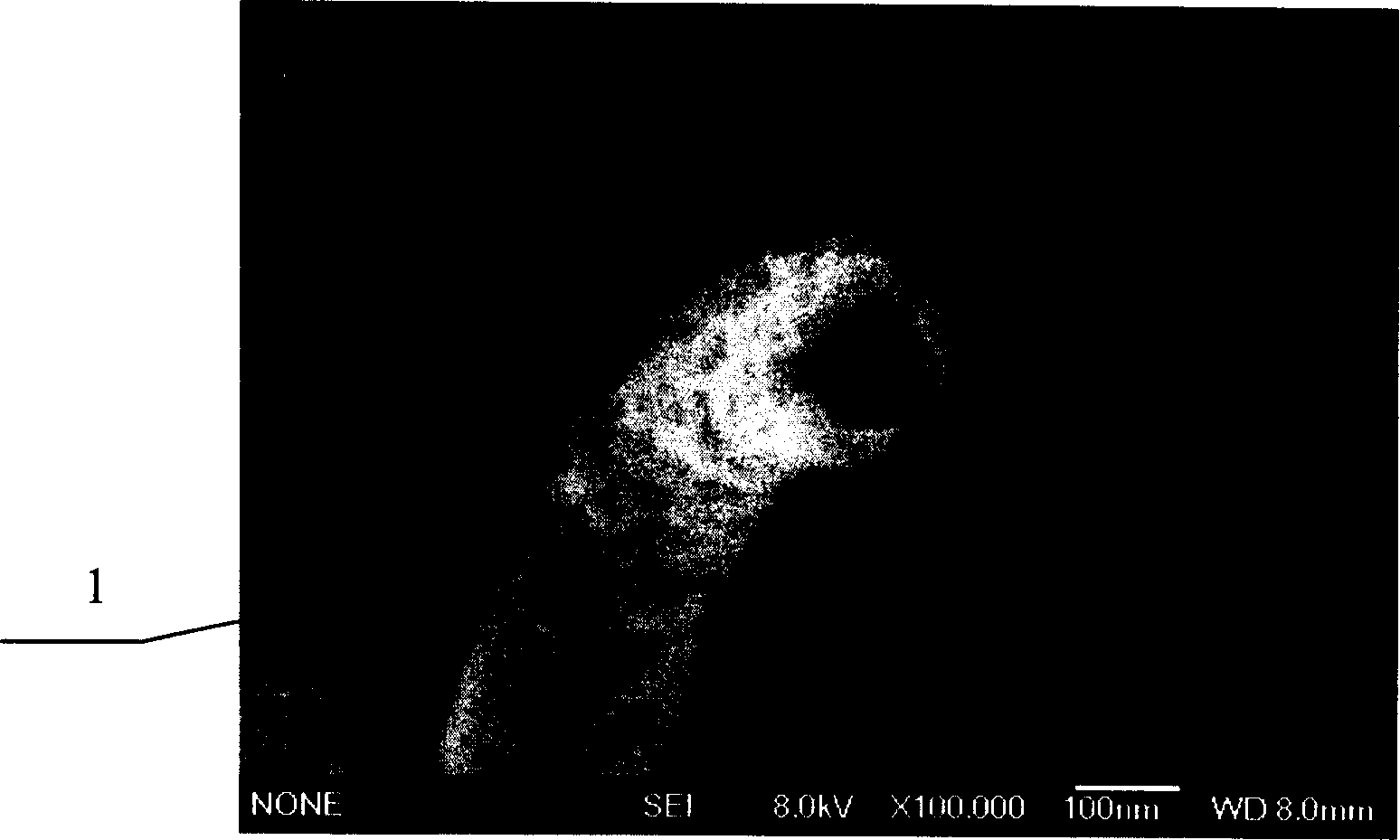

[0026] A preparation method for preparing nanometer metal tubes by template electroless plating, comprising the following sequential steps:

[0027] (1) Rinse the carbon nanofibers in absolute ethanol, then rinse them in a mixed solution of n-butanol and xylene with a volume ratio of 1:3, and clean the carbon nanofibers surface including impurities of small organic molecules;

[0028] (2) In a glass container, place the cleaned carbon nanofibers in nitric acid and sulfuric acid at a volume ratio of ~1:1, at a treatment temperature of 70-75° C., and for a treatment time of 10 minutes.

[0029] (3) Soak the modified carbon nanofibers in a 0.01mol / L sodium lauryl sulfate surfactant solution for 1.5h under ultrasonic stirring conditions; The concentration of hydrochloric acid is 2.50mol / L and the sensitization treatment is carried out in a mixed solution of 2.50mol / L. After washing three times with deionized water, the concentration of palladium dichloride is 0.01mol / L and the con...

specific Embodiment approach 2

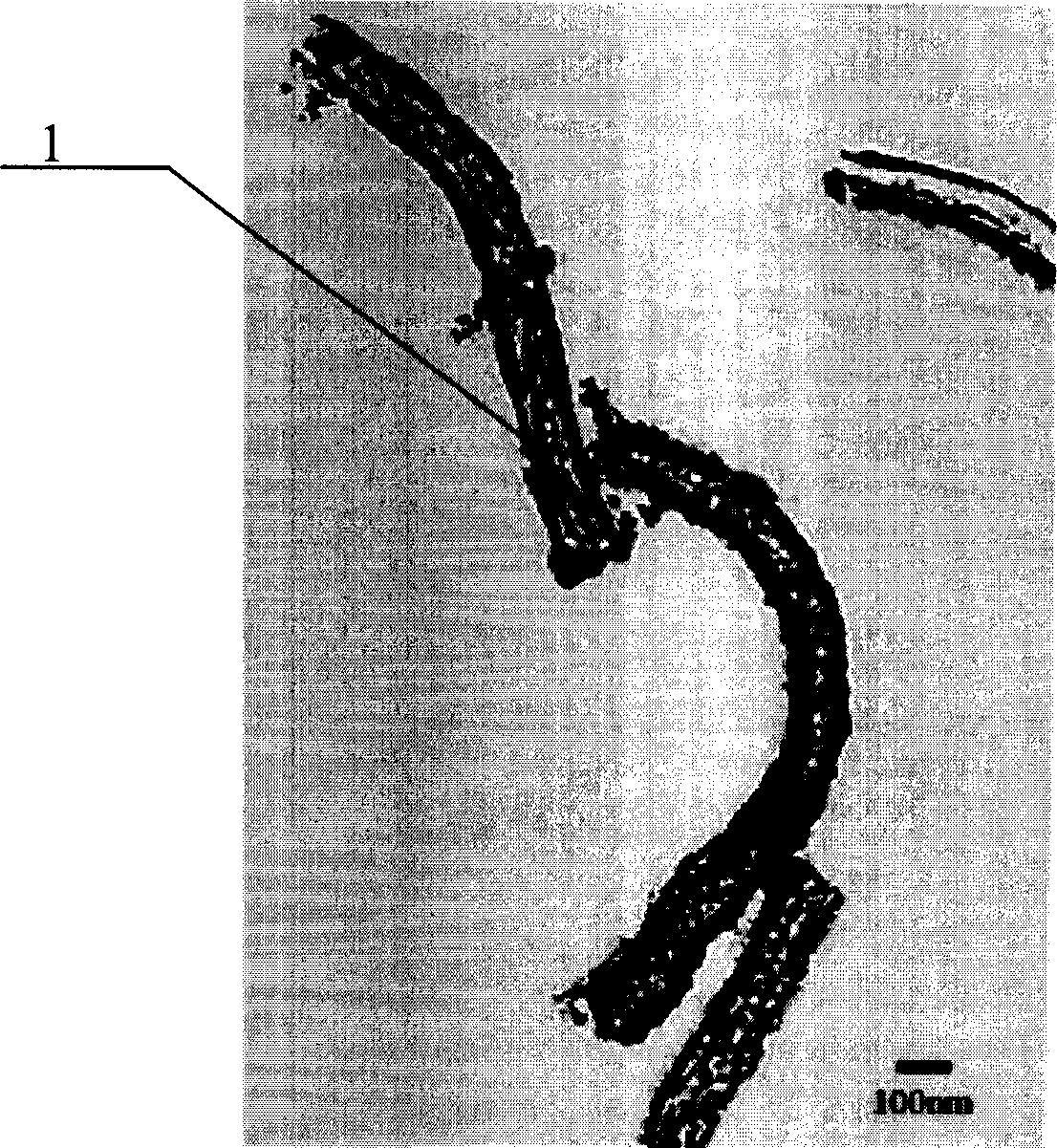

[0032] A preparation method for preparing nanometer metal tubes by template electroless plating, comprising the following sequential steps:

[0033] (1) the nano-polyaniline fiber is rinsed in acetone, and then rinsed in a mixed solution of n-butanol and xylene with a volume ratio of 1:4, and the nano-polyaniline fiber surface is cleaned of impurities including small organic molecules;

[0034] (2) In a glass container, place the cleaned nano-polyaniline fibers in a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 1: 1 for surface treatment at room temperature for 20 minutes;

[0035] (3) Soak the modified nano-polyaniline fiber in 0.01mol / L sodium lauryl sulfate and 0.01mol / L nonylphenol polyoxyethylene ether solution under ultrasonic stirring condition for 1.0h; after that, first Be that 0.50mol / L, hydrochloric acid concentration carry out the sensitization treatment of 10min in the mixed solution of 0.50mol / L, hydrochloric aci...

specific Embodiment approach 3

[0038] A preparation method for preparing nanometer metal tubes by template electroless plating, comprising the following sequential steps:

[0039] (1) Rinse the carbon nanofibers in absolute ethanol, then rinse them in a mixed solution of n-butanol and xylene with a volume ratio of 1:5, and clean the carbon nanofibers surface including impurities of small organic molecules;

[0040] (2) In a glass container, place the cleaned carbon nanofibers in a mixed solution of concentrated nitric acid and concentrated sulfuric acid with a volume ratio of 2:1 for surface treatment at room temperature for 15 minutes;

[0041] (3) Soak the modified carbon nanofibers in 0.015mol / L fatty alcohol polyoxyethylene ether surfactant solution under ultrasonic stirring condition for 1.2h; The concentration of hydrochloric acid is 3.00mol / L mixed solution for 7min to carry out the sensitization treatment, after using deionized water to wash three times, the concentration of palladium dichloride is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com