Method for preparing nano silicate fiber and rubber composite material

A technology of nano-silicate and composite materials, which is applied in the field of preparing nano-silicate fibers and rubber composite materials, can solve the problems of high cost and complicated process, and achieve the effect of low cost, mature technology and remarkable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Dry treatment of FS: pre-mix 100gFS in a high-speed mixer for 5min to make it fluffy, then add modifier: a mixed solution of 0.5g silane coupling agent Si69 and 2.5ml ethanol, stir for 10min, and make Mix the modifier and FS evenly, and then add the release agent: 10g of sulfonated castor oil, mix evenly, and dry at 82°C for 2 hours to obtain the modified FS with fine particles of 5-40μm.

[0033] On the double-roll mill, add 100g of natural rubber for mastication, then add activator: 7g of zinc oxide and 3g of stearic acid, accelerator: 0.5g each of DM and CZ, then add 50g of the above-mentioned modified FS, and finally add vulcanization Agent: sulfur 2g, mixed evenly to obtain rubber compound. The mixed rubber was vulcanized at 140°C to obtain a composite material of nano-silicate fiber and natural rubber, and its mechanical properties are shown in Table 1.

Embodiment 2

[0034] Example 2 On-site treatment of FS: Add release agent: 400g styrene-butadiene rubber to a 1.0L internal mixer, masticate for 30 seconds, add 400gFS and modifier: 80g silane coupling agent KH570, knead at 130°C for 5min A modified FS was obtained.

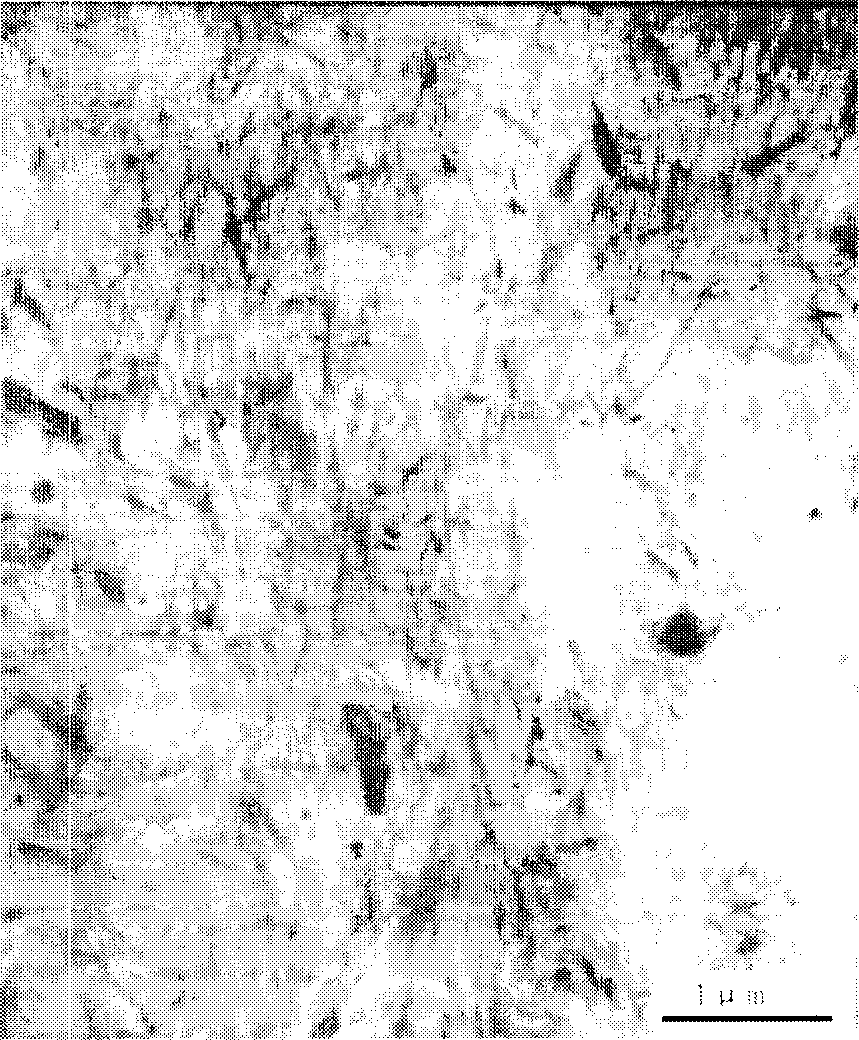

[0035] Add 100g of styrene-butadiene rubber to the double-roll mill for masticating, then add 40g of the above-mentioned modified FS, and then add vulcanizing agent: 0.8g of dicumyl peroxide, and mix evenly to obtain a rubber compound. Finally, it was vulcanized at 160°C to obtain a composite material of nano-silicate fiber and styrene-butadiene rubber. The mechanical properties are shown in Table 1, and the transmission electron microscope photos are shown in figure 1 . From figure 1 It can be seen that the modified FS obtained by on-site treatment can be dissociated into fibers with a diameter of less than 100 nm and uniformly dispersed in the styrene-butadiene rubber, and the dispersibility of the modified FS is very good...

Embodiment 3

[0036] Example 3 Dry treatment of FS: The treatment process is the same as in Example 1, except for the modifier: the amount and type of silane coupling agent are the same as in Example 2, and the release agent is 5 g of castor oil.

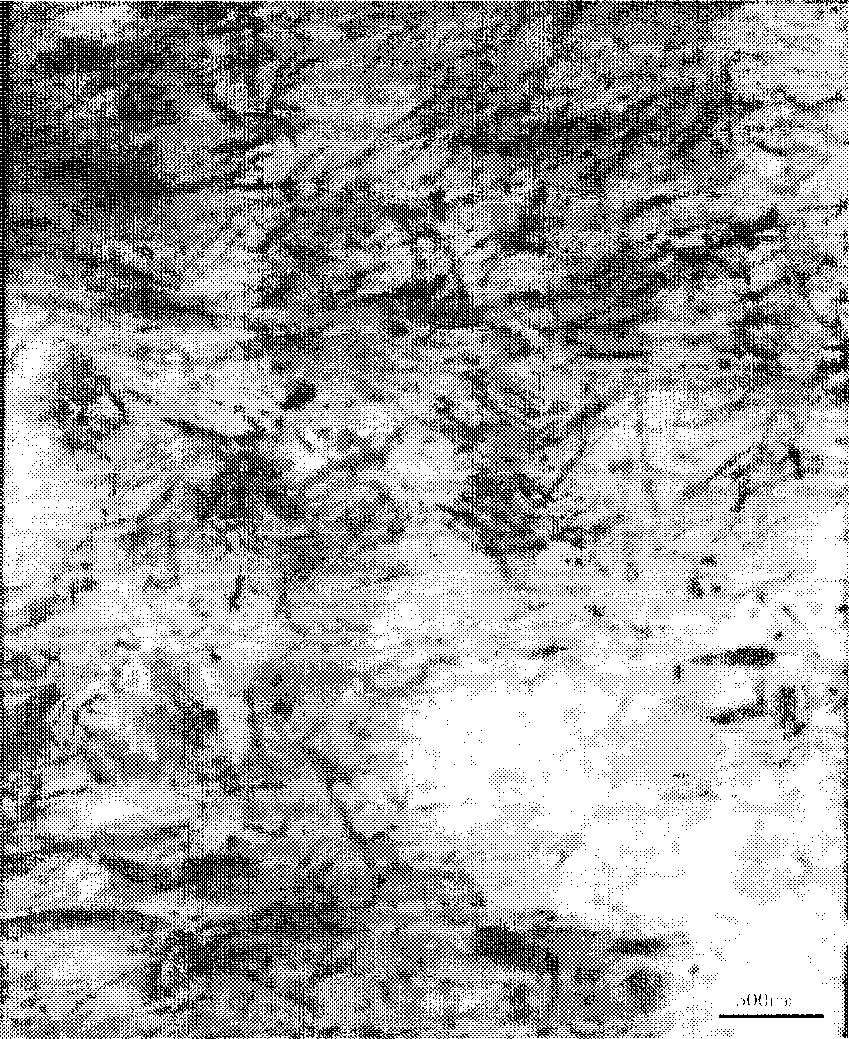

[0037] The preparation process of the composite material is the same as in Example 2, and its mechanical properties are shown in Table 1. Transmission electron microscope pictures see figure 1 . It can be seen from Table 1 that the composite material has high hardness, 100% modulus stress, tensile strength, tear strength and high elongation, which are equivalent to the mechanical properties of the composite material obtained in Example 2. From figure 2 It can be seen that the modified FS obtained by dry treatment can be dissociated into fibers with a diameter of less than 100 nm and uniformly dispersed in the styrene-butadiene rubber, and the dispersibility of the modified FS is very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com