Double-template method hydroxyethyl cellulose modified alginate microsphere and its preparation method

A technology of hydroxyethyl cellulose and alginate, which is applied in material inspection products, biological testing and other directions, can solve the problems of poor compatibility, poor stability, and high amount of modified components, and achieve good compatibility and price. Easily available and inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of hydroxyethyl cellulose modified alginate microspheres (Alg / HEC) by emulsion template method:

[0040] (1) Dissolve 0.6g of sodium alginate in 20ml of deionized water to prepare a 3% sodium alginate solution, add 1ml of 2% HEC solution, mix well, add 1g of liquid paraffin, 0.1g of Span85, 0.4g of Tw80, and stir for 1h , to become a uniform milky white emulsion;

[0041] (2) Disperse the emulsion in the organic oil phase under constant mechanical stirring. The composition of the oil phase is: chloroform 16ml, n-hexane 24ml; surfactant: span80 0.8g, span85 0.8g;

[0042] (3) After stirring for 5 minutes, add 5 ml of 2% PVP aqueous solution (cosurfactant) to the suspension system, and continue stirring for 15 minutes;

[0043] (4) Add 20ml 3% CaCl 2 , stir for 30min;

[0044] (5) The microspheres were separated from the suspension, rinsed with a large amount of deionized water, and then crosslinked in 5% glutaraldehyde (pH=6.00) crosslinking solution for ...

Embodiment 2

[0057] Preparation of hydroxyethyl cellulose modified alginate microspheres (BSA-Ca-Alg / HEC) by macromolecule template method:

[0058] (1) Add 0.6 g of sodium alginate to 20 ml of 20 μmol / LBSA aqueous solution, after fully dissolving, add 1 ml of 2% HEC solution, and mix well;

[0059] (2) Disperse the mixed liquid in the organic oil phase under the condition of constant speed mechanical stirring. The composition of the oil phase is: chloroform 16ml, n-hexane 24ml; surfactant: span80 0.8g, span85 0.8g;

[0060](3) After stirring for 5 minutes, add 5 ml of 3% PVP aqueous solution (cosurfactant) to the suspension system, and continue stirring for 15 minutes;

[0061] (4) Add 20ml 3% CaCl 2 , stir for 30min;

[0062] (5) The microspheres were separated from the suspension, rinsed with a large amount of deionized water, and then crosslinked in 5% glutaraldehyde (pH=6.00) crosslinking solution for 48 hours;

[0063] (6) The fully cross-linked microspheres were taken out of the...

Embodiment 3

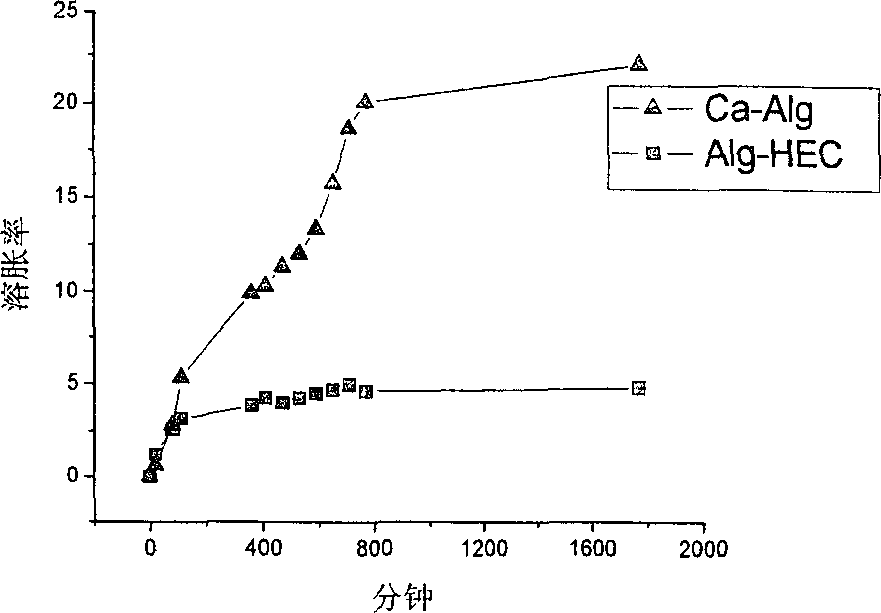

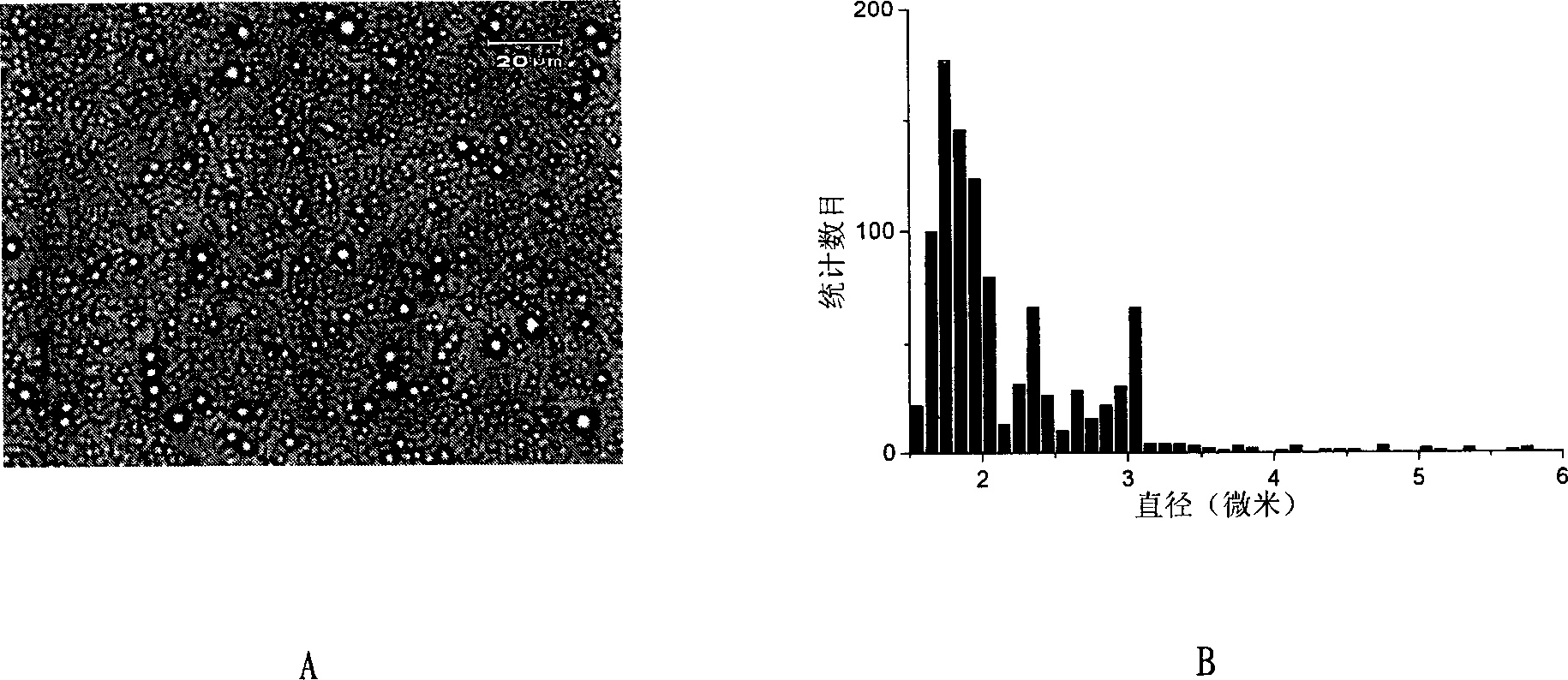

[0082] Fully mix 20ml of 3% sodium alginate solution with 1.5ml of 2% hydroxyethyl cellulose, add 0.8g of liquid paraffin, 0.16g of Span85, and 0.64g of Tween 80 to the mixture, and stir at high speed for 1 hour to obtain an emulsion. Take a small amount of the prepared emulsion with a rubber dropper, drop it on the cover glass, and quickly place it under an optical microscope (model BX51TF. Manufacturer: Olympus Company) connected with a digital camera to take pictures of the morphology of the emulsion. image 3 A, use Photoshop software to image 3 The emulsion particles in A were used for size statistics, and the attached image 3 b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com