Process for producing chloromycetin molecular engram polymer microsphere

A molecularly imprinted polymer technology, applied in the field of bioengineering, can solve the problems of molecularly imprinted polymer molecular recognition and selectivity decline, irregular particle shape, low yield, etc., to achieve great promotion and application value, accurate separation, The effect of high-efficiency enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 100ml of 4% PVA1788 into the four-neck flask, blow nitrogen gas for 10min, and stir at the same time, 400rpm.

[0024] In another container, 0.8ml DAM, 5ml EDMA, 10ml octanol and 0.32g chloramphenicol from which the polymerization inhibitor has been removed were mixed ultrasonically for 20min, then 120mg AIBN and 5ml chloroform were added to continue ultrasonication for 5min, and ice was added during ultrasonication. block, keep cold.

[0025] Keep the stirring speed, and add the prepared monomer phase into the four-neck flask to ensure good monomer dispersion. Continuous nitrogen flow, 70°C, 24h. The resulting polymer was subjected to elution treatment.

[0026] After the polymerization reaction finishes, the obtained polymer is filtered out and rinsed with water three times, then poured into a 200ml beaker, stirred with 80°C double distilled water for 60min, washed three times with 50ml methanol, twice with 50ml acetone (washing away swelling agent, residual org...

Embodiment 2

[0028] Add 100ml of 4% PVA1788 into the four-neck flask, blow nitrogen gas for 10min, and stir at the same time, 400rpm.

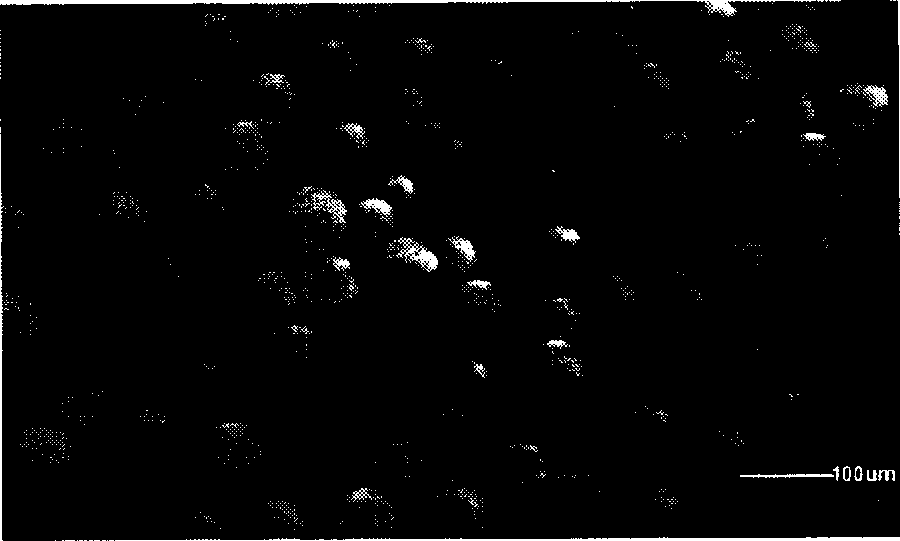

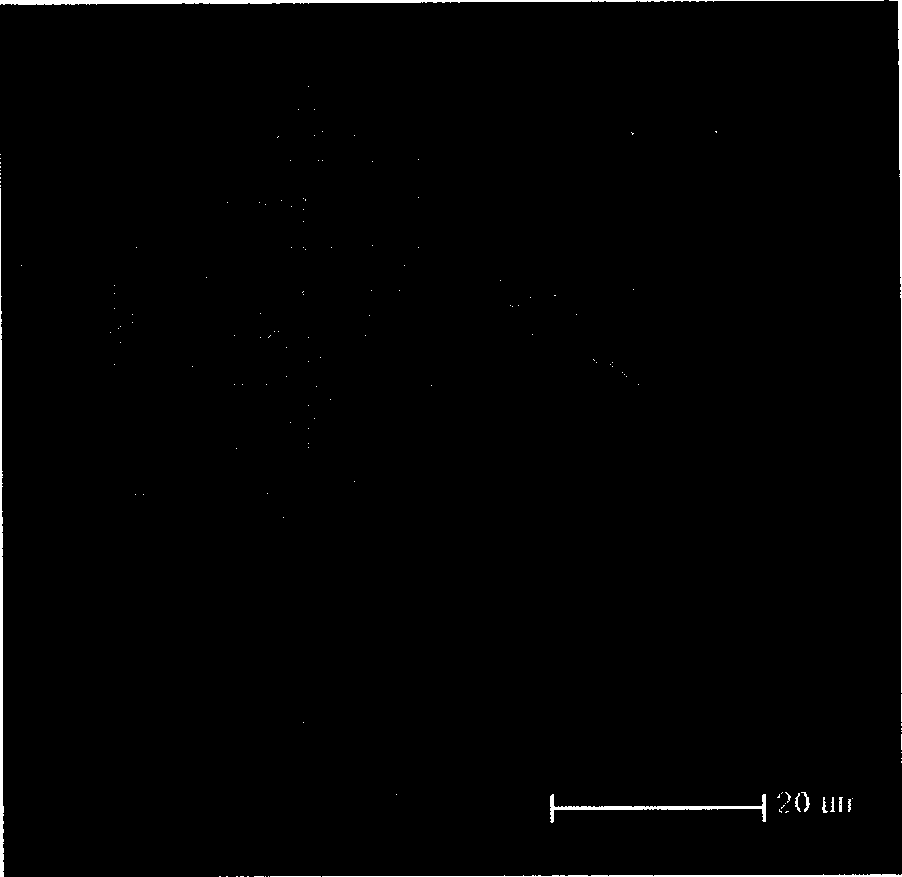

[0029] In another container, 0.8ml St, 5ml EGDMA and 10ml octanol, 0.32g chloramphenicol that have removed polymerization inhibitor, other operation is the same as embodiment 1. Finally, microspheres with an average particle size of about 120 μm and many small holes on the surface are obtained, and the inventive effect is basically equivalent to that of figure 1 , 2 shown.

Embodiment 3

[0031] Add 100ml of 4% PVA1788 into the four-necked flask, blow nitrogen gas for 10min, and stir at the same time, 350rpm.

[0032] In another container, 0.8ml DAM, 5ml EGDMA, 10ml octanol and 0.32g chloramphenicol from which the polymerization inhibitor has been removed were ultrasonically mixed for 20min, then 120mg AIBN and 5ml chloroform were added to continue ultrasonication for 5min, and ice was added during ultrasonication. block, keep cold.

[0033] Keep the stirring speed, and add the prepared monomer phase into the four-neck flask to ensure good monomer dispersion. Continuous nitrogen flow, 70°C, 24h. Other operations are the same as in Example 1. Finally, microspheres with an average particle size of about 90 μm and many small holes on the surface are obtained, and the inventive effect is basically equivalent to that of figure 1 , 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com