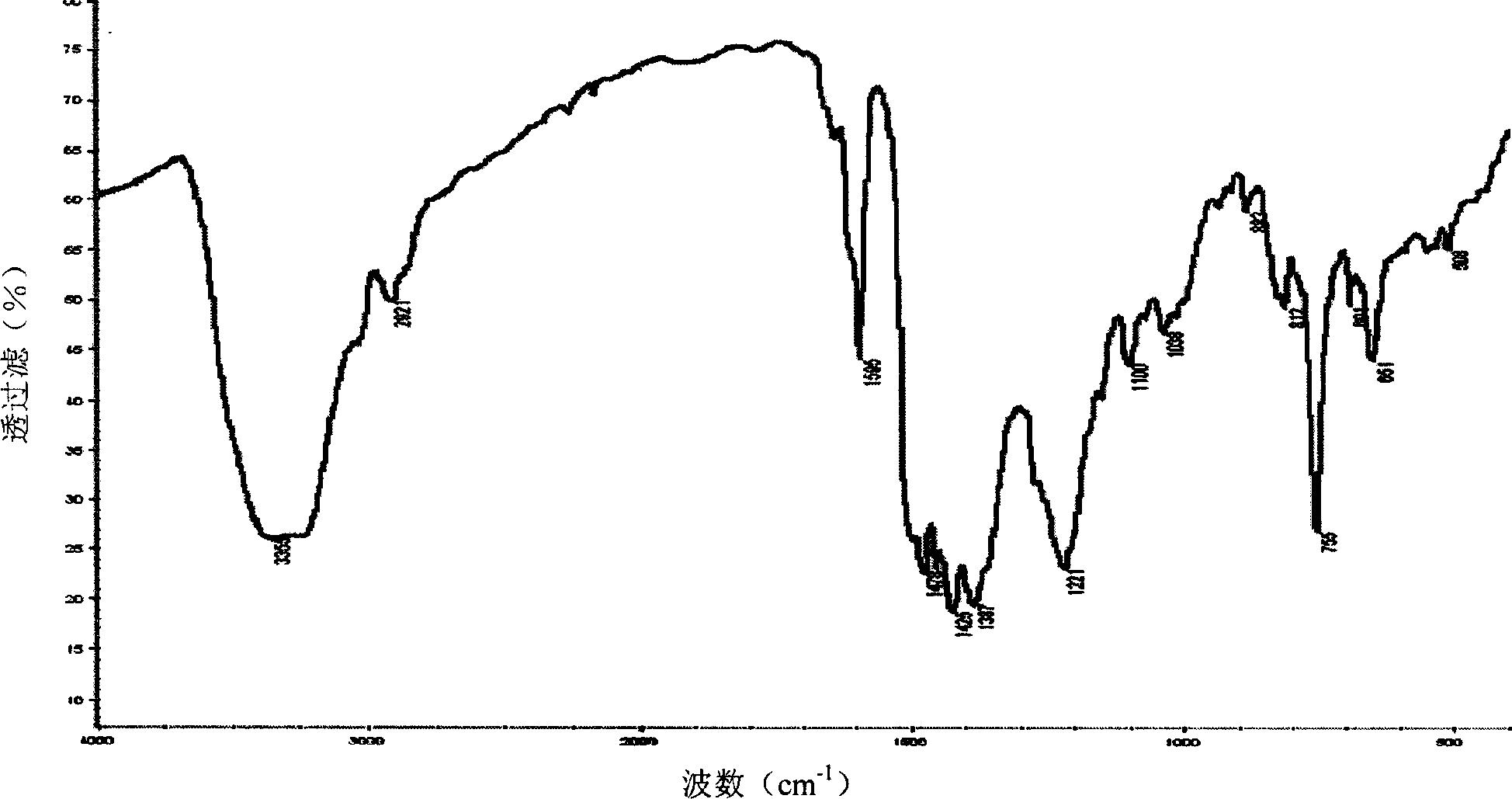

Process for in-situ preparation of nano silicon dioxide and boron modified phenol-formaldehyde resin nano composites

A nano-composite material and nano-silica technology, which is applied in the field of in-situ preparation of nano-silica/boron-modified phenolic resin nanocomposites, can solve the problems of high brittleness, poor toughness, and poor heat resistance of phenolic resin. The effect of achieving excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step (1): According to the molar ratio of boric acid / phenol=1 / 3, 28.2g of phenol and 40ml of toluene solution were added into a four-necked flask equipped with a condenser, a thermometer, an electric stirrer and a thermocouple. Raise the temperature to 90°C, then add 6.2g of boric acid, and at the same time adjust the pH value of the solution in the four-neck flask with 0.1mol / L NaOH solution. Dehydration under vacuum. Stop pumping when the liquid is clear and slightly orange, and when there is no water after pumping for a long time;

[0025] Step (2): Dissolve 1 g of surface treatment agent KH570 with 50 ml of toluene solvent. Then add 1.4g gas-phase method nano-SiO to the solution 2 (average diameter 12nm), disperse for 10 minutes under the action of 200kHz ultrasonic waves, and make surface-treated nano-SiO after separating the solvent 2 ; The surface-treated nano-SiO 2 Add to the borate solution prepared in step (1), and disperse for 10 minutes under the action ...

Embodiment 2

[0031] Step (1): According to the molar ratio of boric acid / phenol=1 / 2, 18.8g of phenol and 80ml of ethanol solution are added to a four-necked flask equipped with a condenser, a thermometer, an electric stirrer and a thermocouple. Raise the temperature to 75°C, then add 6.2g of boric acid, and at the same time adjust the pH value of the solution in the four-neck flask with 0.1mol / L KOH solution, when the pH=8, make the solution react at a temperature range of 95°C, while Dehydration under vacuum. Stop pumping when the liquid is clear and slightly orange, and when there is no water after pumping for a long time;

[0032] Step (2): Dissolve 1 g of surface treatment agent KH550 with 100 ml of ethanol solvent. Add 1.59g gas-phase method nano-SiO to the solution again 2 (average diameter 20nm), disperse for 30 minutes under the action of 100kHz ultrasonic waves, and make surface-treated nano-SiO after separating the solvent 2 ; The surface-treated nano-SiO 2 Add to the borate ...

Embodiment 3

[0036] Step (1): According to the molar ratio of boric acid / phenol=2 / 1, 9.4g of phenol and 20ml of isobutanol solution were added to a four-necked flask equipped with a condenser, a thermometer, an electric stirrer and a thermocouple. Heat up to 120°C, then add 12.4g of boric acid, while using 0.1mol / L of Ca(OH) 2 The solution adjusts the pH value of the solution in the four-necked flask, and when the pH value is between 6, the solution is reacted at a temperature range of 130° C. and dehydrated under vacuum at the same time. Stop pumping when the liquid is clear and slightly orange, and when there is no water after pumping for a long time;

[0037] Step (2): Dissolve 1 g of surface treatment agent NDZ201 with 200 ml of n-butanol solvent. Then add 1.75g precipitation method nano-SiO to the solution 2 (average diameter 35nm), disperse for 30 minutes under the action of 40kHz ultrasonic waves, and make surface-treated nano-SiO after separating the solvent 2 ; The surface-tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com