Environment-protection type coated release-controlled urea and preparing method

A controlled-release urea, environment-friendly technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer mixture, etc., can solve the problems of long release period of controlled-release urea particles, difficult degradation of membrane materials, long complete release time, etc., to achieve enhanced soil Water retention, improved pore properties, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

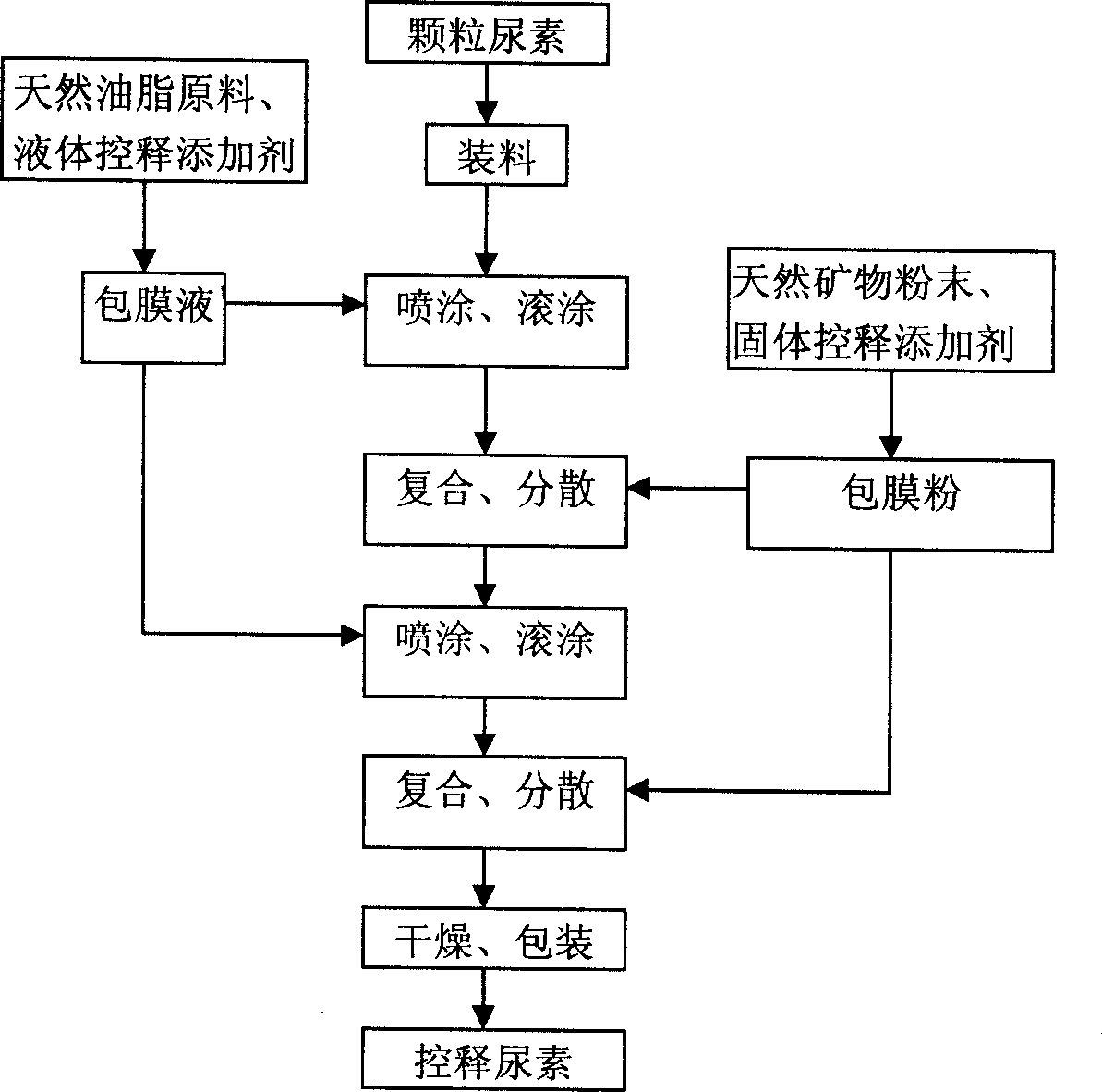

Method used

Image

Examples

Embodiment 1

[0033] The first step: main material equipment: sieve, grade and dry the granular urea, weigh 1000 grams of 2-3mm granular urea for later use;

[0034] Step 2: Prepare the coating solution: weigh 35 grams of tung oil, 0.9 grams of liquid paraffin, and 0.15 grams of cobalt catalyst; stir them on an electric mixer or a magnetic stirrer, mix well and make a coating solution for use ;

[0035] The third step: prepare coating powder: take 70 grams of talcum powder and 5 grams of calcium stearate respectively, put them in a mixer and mix them evenly to make coating powder for later use;

[0036] Step 4: Put 1,000 grams of granular urea into the drum-type or cylinder-type coating machine, set the speed of the coating machine to 40 rpm, and start the coating machine so that the granular urea can roll well in the coating machine; Half of the coating liquid prepared in the second step is evenly sprayed on the surface of urea, and blown with 50°C hot air to make the surface sticky;

[...

Embodiment 2

[0041] Step 1: Sieve, classify and dry the granular urea, weigh 1000 grams of 3-4mm granular urea for use;

[0042] Step 2: Weigh 50 grams of tung oil, 0.825 grams of liquid paraffin, 0.15 grams of cobalt catalyst, and 0.1 grams of amphiphilic active agent OP and mix them uniformly to form a coating solution.

[0043] Step 3: Mix 30 grams of talcum powder and 1 gram of calcium stearate in a mixer to make coating powder.

[0044] Step 4: Set the speed of the coating machine to 15 rpm, spray 1 / 2 of the coating liquid evenly, and blow it with hot air at 40°C;

[0045] Step 5: Sprinkle the coating powder prepared in the third step on the granular urea slowly, continue to rotate the coating machine, and blow it with hot air to harden the surface;

[0046] Step 6: Repeat step 4, then weigh 30 grams of talcum powder and sprinkle it evenly on the surface of urea granules. After coating evenly, add 0.825 grams of liquid paraffin and roll the urea granules for a certain period of time....

Embodiment 3

[0048] The first step: Weigh 1000 grams of 4-5mm granular urea, 20 grams of tung oil, 28 grams of talcum powder, 0.45 grams of liquid paraffin, 5 grams of calcium stearate (or magnesium stearate), 0.1 grams of cobalt catalyst, amphiphilic activity Agent 0P 0.1 g;

[0049] Step 2: Fully mix tung oil, liquid paraffin, and cobalt catalyst to make coating liquid;

[0050] Step 3: Mix 1 / 2 talcum powder, calcium stearate or magnesium stearate in a mixer to make coating powder;

[0051] Step 4: Set the speed of the coating machine to 30 rpm, take half of the liquid prepared in the second step, and spray it evenly, and blow it with hot air to make the surface sticky;

[0052] Step 5: Sprinkle the remaining 1 / 2 talcum powder on the granular urea slowly, continue to rotate the coating machine, and blow it with hot air to harden the surface. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com