Method for preparing biological diesel oil from saurauia tristyla var oldhamii oil

A technology of biodiesel and wax gourd, which is applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of production, scale or complex industrial production of components, poor safety, large investment, etc., and achieve simple cost , good quality, good effect of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

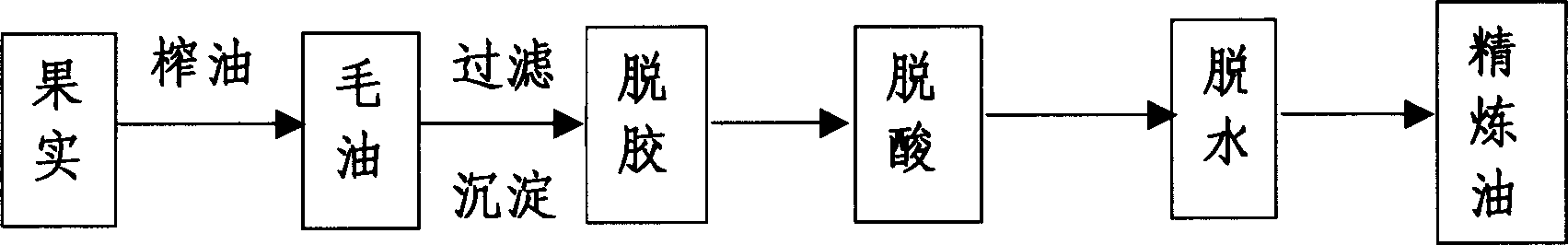

[0017] 1. Production process of wax gourd crude oil

[0018] 1. Raw material watermelon fruit

[0019] Every year in late October, the fruit that becomes red (with a little yellow fruit) on the water wax gourd tree is picked, dried, and stored in storage.

[0020] 2. Pretreatment

[0021] The water wax gourd fruit stored in the air to be dried is removed various impurities in the fruit by air separation, magnetic separation and other means.

[0022] 3. Press to extract oil

[0023] 100 jin of wax gourd fruit from which impurities have been removed are put into a hydraulic oil press for continuous pressing to obtain 24.4 jin of wax gourd crude oil. In order to improve the oil yield, according to the equipment and process conditions, the pressed oil cake is leached to extract oil. The fatty acid component of the water wax gourd crude oil that obtains with above method is: WT%

[0024] palmitic acid C 16 :0 13.9

[0025] palmitenoic acid C 16 : 1 6.4

[0026] stearic aci...

Embodiment 2

[0045] One, the wax gourd crude oil production process is identical with embodiment 1.

[0046] 2. Refining process of wax gourd oil

[0047] (1) Degumming

[0048] Take 1,500 grams (about 1,800 ml) of pressed oil, add 45 grams of water, stir and heat the oil to 65°C, add water within 9 minutes, continue stirring at a speed of 60 rpm, stop stirring after 30 minutes, After keeping warm for 3 hours, the oil and soapstock were obviously separated, and the oil sample was taken out for inspection, and the phosphorus content was 15×10 -6 mg / Kg.

[0049] (2) Deacidification

[0050] Get 1400 grams of degummed oil, the acid value of this oil is 10, needs 22 · Be through calculation - Sodium hydroxide lye 80 grams. Adjust the oil temperature to 30°C, stir and add lye, the lye is added within 10 minutes, the stirring speed is 60 rpm at the beginning, and when the oil and soap are clearly separated, reduce the speed to 30 rpm. At the same time, the oil temperature was heated to 60°...

Embodiment 3

[0055] One, the wax gourd crude oil production process is identical with embodiment 1.

[0056] Two, the refining process of wax gourd oil is identical with embodiment 2.

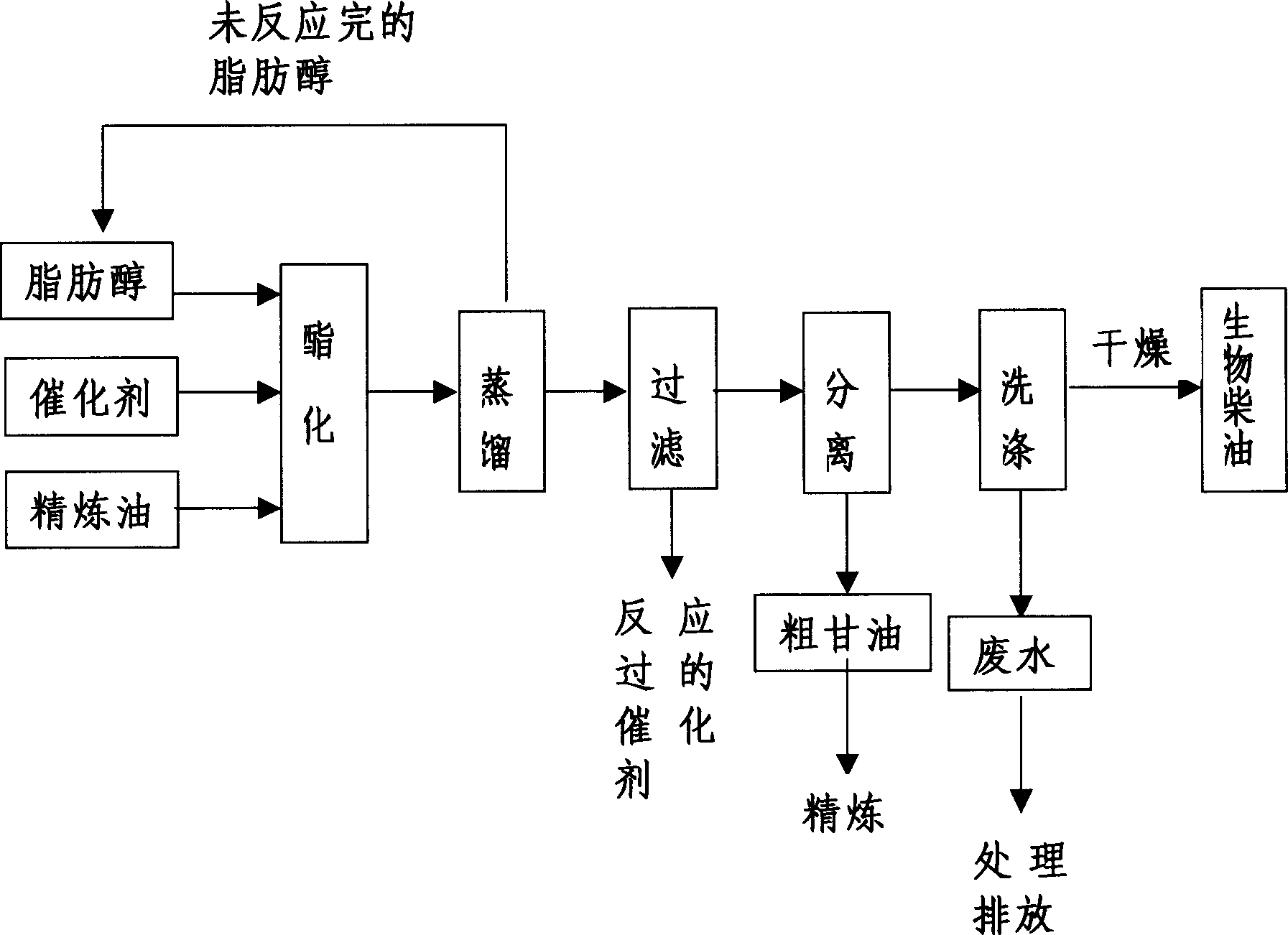

[0057] 3. Esterification process

[0058] Take 415 grams of refined and dried wax gourd refined oil, add 50 grams of methanol, and 2.08 grams of catalyst potassium hydroxide, mix methanol and potassium hydroxide and pour it into a 1000-milliliter Erlenmeyer flask containing 415 grams of wax gourd refined oil, and heat to 40°C, stirred and reacted for 60 minutes, stopped stirring, heated to 80°C, and distilled off residual methanol. Cooling and standing for 60 minutes, the light phase crude biodiesel and heavy phase crude glycerin were separated. The potassium hydroxide residue in the lower heavy phase was filtered off to obtain 70 grams of crude glycerol. Add 40 grams of 8% dilute sulfuric acid to the light-phase crude biodiesel, wash it, and then wash it twice with warm water at about 50°C. After draini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com