Process for preparing nano ZnO

A nanostructure and nanocomb technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as poor controllability, high temperature requirements, and process incompatibility, and achieve simple methods, low cost, and mild conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

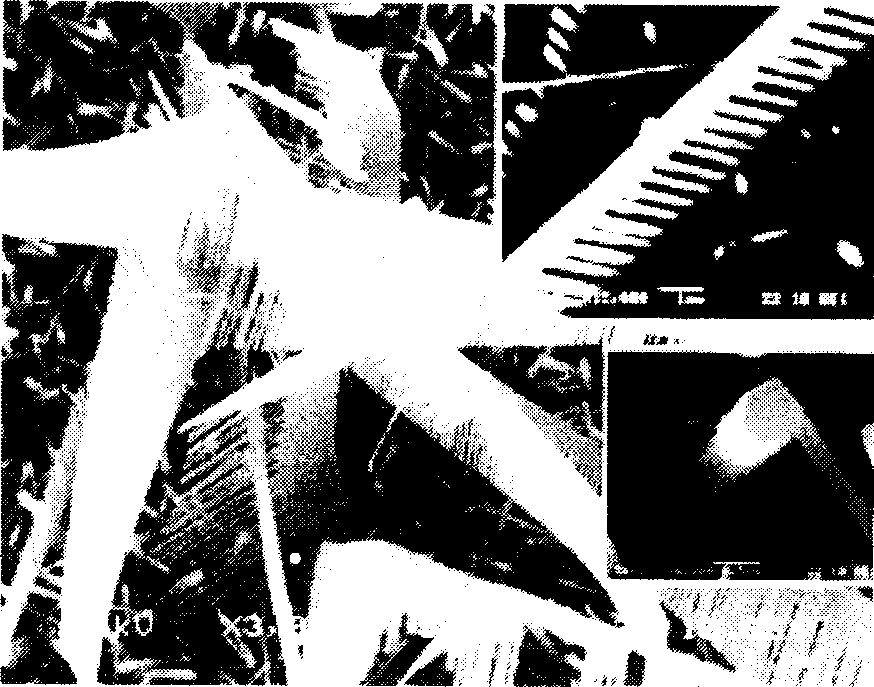

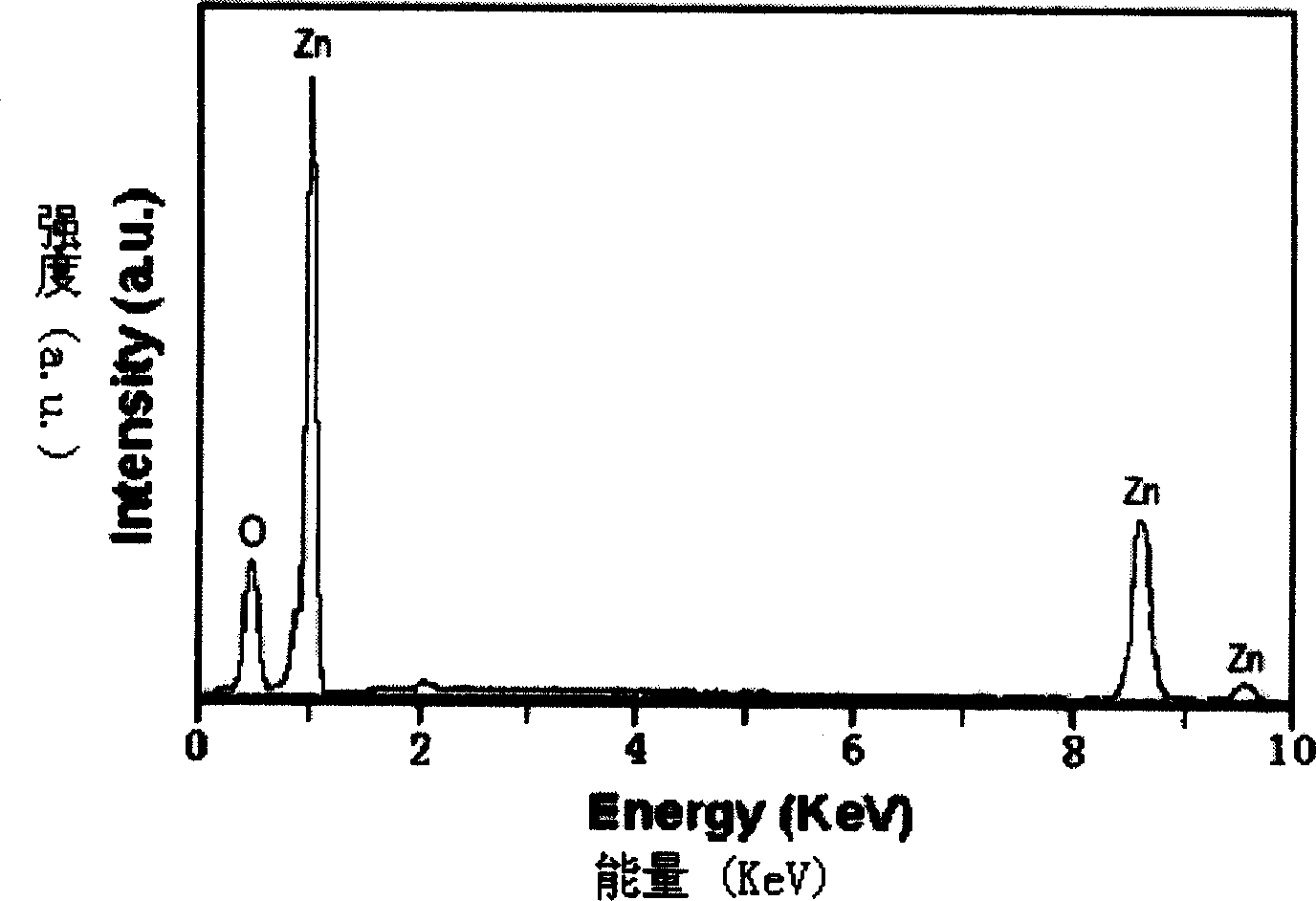

[0022] A. Synthesis of ZnO nanocomb structure and ZnO nanorods

[0023] 1) First, the silicon wafer is polished with fine sandpaper to make the surface rough and provide nucleation points for growth materials.

[0024] 2) sequentially use 1:3 concentrated sulfuric acid and hydrogen peroxide (concentration is 30%), 1:3:3 ammonia water (concentration is 27%), hydrogen peroxide and deionized water; and 1:3:3 hydrochloric acid (concentration is 38%), hydrogen peroxide and deionized water (both in volume ratio) were heated and cleaned with a heating furnace to clean the polished silicon wafer for about 8 minutes each.

[0025] 3) Zn (purity 99.99%) powder is placed on a quartz boat, and then a layer of mixture of zinc oxide and graphite powder is covered on it. Place the cleaned silicon wafer on the mixture of the three, and the vertical distance between them is about 1mm.

[0026] 4) Heat the furnace to 650°C and keep it for a few minutes, then place the prepared quartz boat in ...

Embodiment 2

[0035] A. Synthesis of ZnO nanocomb structure and ZnO nanorods

[0036] Same as step A of embodiment 1

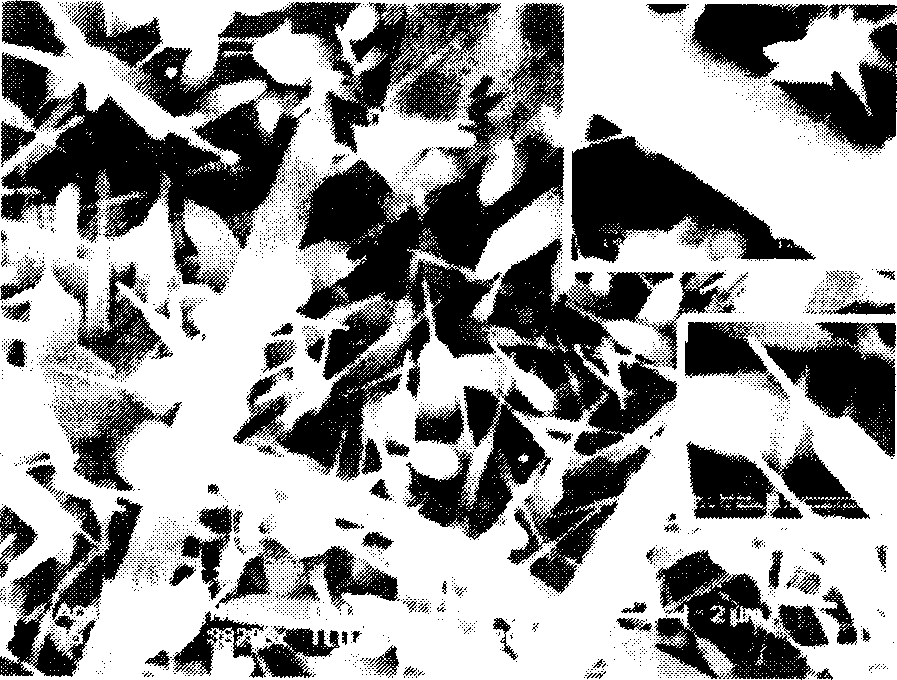

[0037] B. Dissolve 1.0 g of thiourea in 100 ml of deionized water as a spare solution. Then put the silicon chip with ZnO nanostructure synthesized by thermal evaporation into the standby solution. After keeping at room temperature for 15 hours, take out the silicon wafer and wash it several times with deionized water, and finally dry it in an oven at 95°C. The etching principle is that thiourea dissolves in deionized water and undergoes a reversible reaction to produce weak hydrogen sulfuric acid. the essence lies in , thus realizing the etching of ZnO nanostructures.

Embodiment 3

[0039] A. Synthesis of ZnO nanocomb structure and ZnO nanorods

[0040] Same as step A of embodiment 1

[0041] B. Dissolve 1.3g of thiourea in 100ml of deionized water as a spare solution. Then put the silicon chip with ZnO nanostructure synthesized by thermal evaporation into the standby solution. After keeping at room temperature for 8 hours, take out the silicon wafer and wash it several times with deionized water, and finally dry it in an oven at 95°C. The etching principle is that thiourea dissolves in deionized water and undergoes a reversible reaction to produce weak hydrogen sulfuric acid. the essence lies in , thus realizing the etching of ZnO nanostructures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com