Polymer microsphere containing inorganic nano microparticles, and its preparing method and use

An inorganic nano- and nano-particle technology, applied in biological testing, material inspection, etc., can solve problems such as the inability to control the morphology and crystallinity of the nano-particle surface structure, and the lack of strong enough interaction between the nano-particle and the polymer sphere. , to achieve the effect of convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

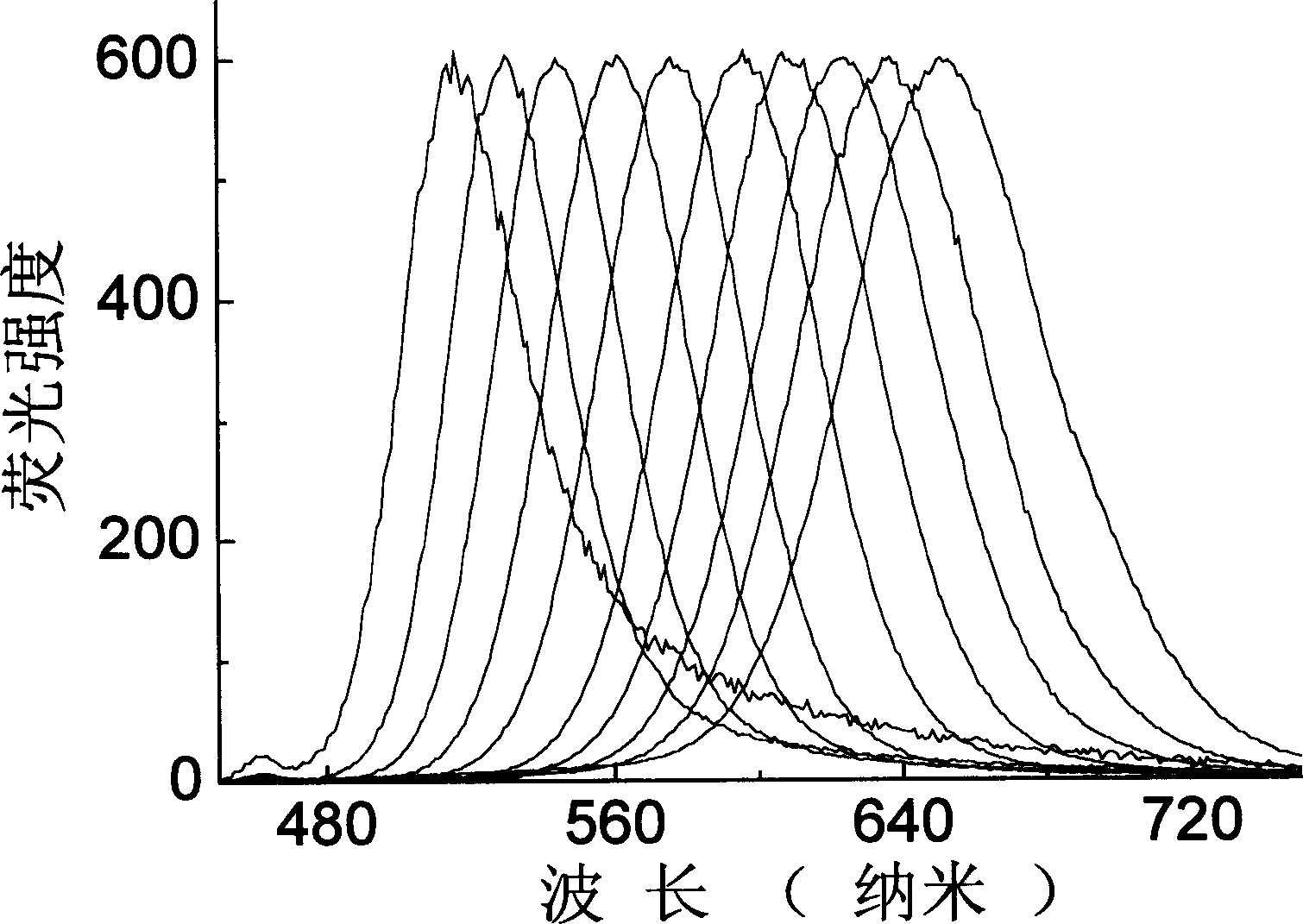

[0069] Weigh 1.315g cadmium perchlorate (Cd(ClO 4 ) 2 ·6H 2 O) Add to 150mL of deoxygenated secondary water, then add 0.55mL of thioglycolic acid as a modifier, adjust its pH value to 11.2 with 1M sodium hydroxide solution to form a solution containing mercapto compounds and cadmium ions. On the other hand, take 30mL of 0.5M sulfuric acid solution and inject it into a container containing 0.39g of aluminum telluride (Al 2 Te 3 ) in the flask, the generated H 2 Put all the Te into the cadmium ion solution, stir for 15 minutes, and then heat and reflux for 1 minute to 10 days to obtain an aqueous solution of cadmium telluride semiconductor nanoparticles with stable thioglycolic acid and a fluorescent emission center wavelength between 430 and 650 nanometers. Fluorescence spectrum see figure 1 .

Embodiment 2

[0071] Weigh 1.031g cadmium chloride (CdCl 2 2.5H 2 O) Add to 150mL deoxygenated secondary water, then add 0.55mL mercaptopropionic acid as a modifier, adjust its pH value to 11.2 with 1M sodium hydroxide solution to form a solution containing mercapto compounds and cadmium ions. The rest of the steps are the same as in Example 1 to obtain an aqueous solution of cadmium telluride semiconductor nanoparticles with stable mercaptopropionic acid and a central wavelength of fluorescence emission between 430 and 650 nanometers.

Embodiment 3

[0073] Weigh 1.031g cadmium chloride (CdCl 2 2.5H 2 O) Add to 150mL deoxygenated secondary water, then add 0.65mL lipoic acid as a modifier, adjust its pH value to 11.2 with 1M sodium hydroxide solution to form a solution containing mercapto compounds and cadmium ions. The rest of the steps are the same as in Example 1 to obtain an aqueous solution of cadmium telluride semiconductor nanoparticles with stable lipoic acid and a center wavelength of fluorescence emission between 430 and 650 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com