Scintillation substances (variants)

A scintillator and scintillation material technology, applied in crystal growth, polycrystalline material growth, luminescent materials, etc., can solve the problems of inefficient detection of gamma radiation and large loss of crystalline materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

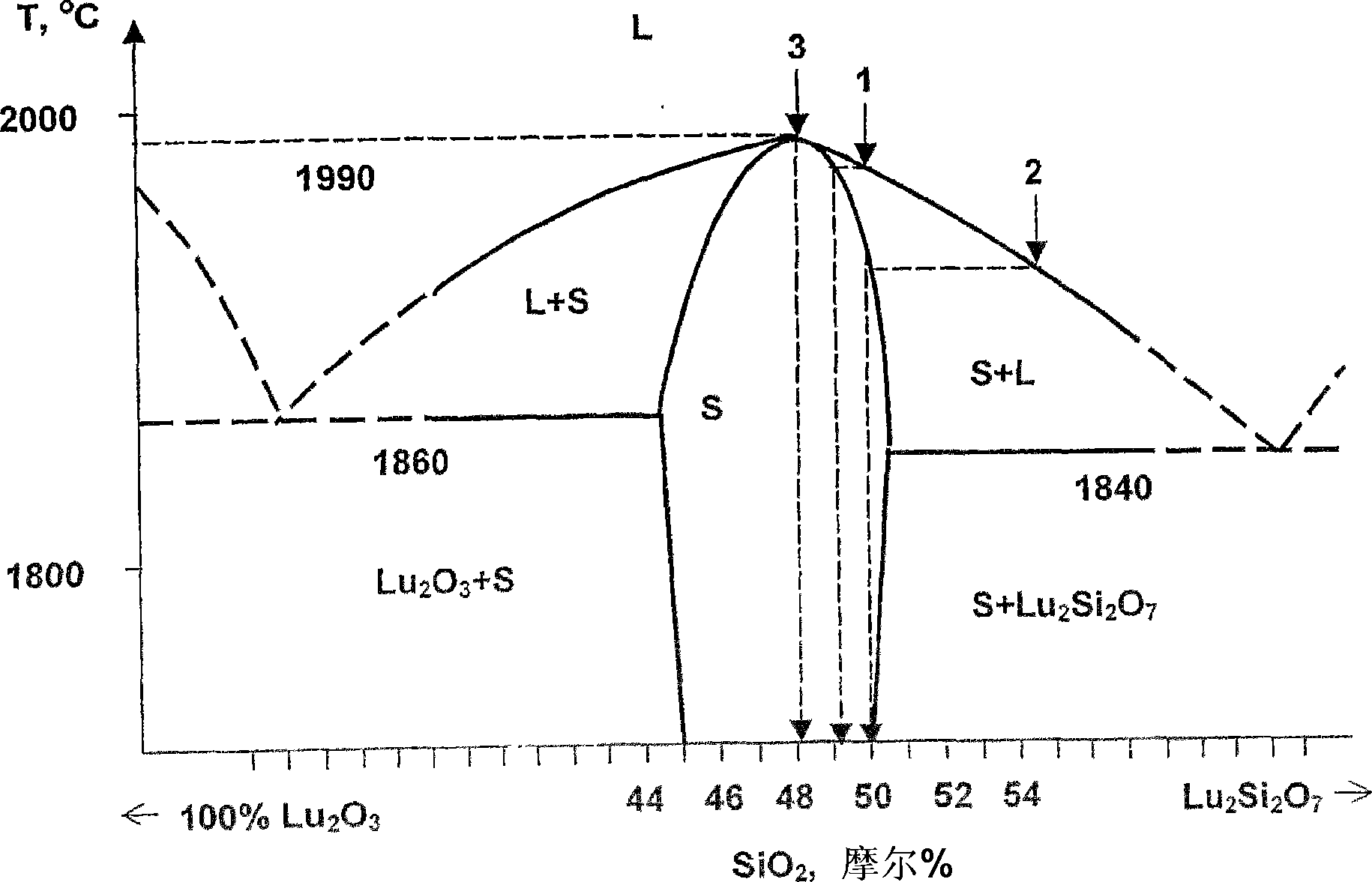

[0168] Example 1. "Reference" Ce:Lu with known Lu / Si=2 2 SiO 5 The growth of crystals, and the growth of crystals with a chemical formula unit ratio of (Lu+Ce) / Si=2.061 (y=0.015), which is outside the composition range of modification 1 of the present invention.

[0169] Due to the large data distribution between the crystal parameters published in different publications, the commercially available Ce:Lu 2 SiO 5 Crystal parameters can be accepted as the most reliable data. LSO crystals with a concentration of cerium ions equal to 0.12at% (or about 0.002f. units) show higher light output, the chemical formula of the reference crystal is Ce 0.002 Lu 1.998 SiO 5 . Considering that the segregation coefficient of cerium ions between the melt and the growing crystal is equal to about k=0.2, it is necessary to add a raw material having a cerium concentration of about 0.6 at% (or chemical formula unit: 0.012f. unit) in the crucible. Lu should be calculated considerin...

Embodiment 2

[0174] Example 2. Verification of the present invention in a specific embodiment—a scintillator manufacturing method. In order to grow large single crystals by the Kyropoulos method according to variants #1, #2, #3 and #4, a crystal with 51.9% (Ce 2 o 3 +Lu 2 o 3 +A 2 o 3 +Li 2 O) / 48.1%SiO 2 Optimal scintillator for the feed composition characterized by the oxide molar ratio. At this oxide ratio, the composition of the melt and crystals is given by the formula Ce x Li q+p Lu 2.076-p-x-z A z Si 0.962 o 5.038-p is characterized, wherein A is at least one element selected from Gd, Sc, Y, La, Eu, Tb, and x is 1×10 -4 The value between f. unit and 0.02f. unit, z is the value not exceeding 0.05f. unit, and q+p is the value not exceeding 0.025f. unit.

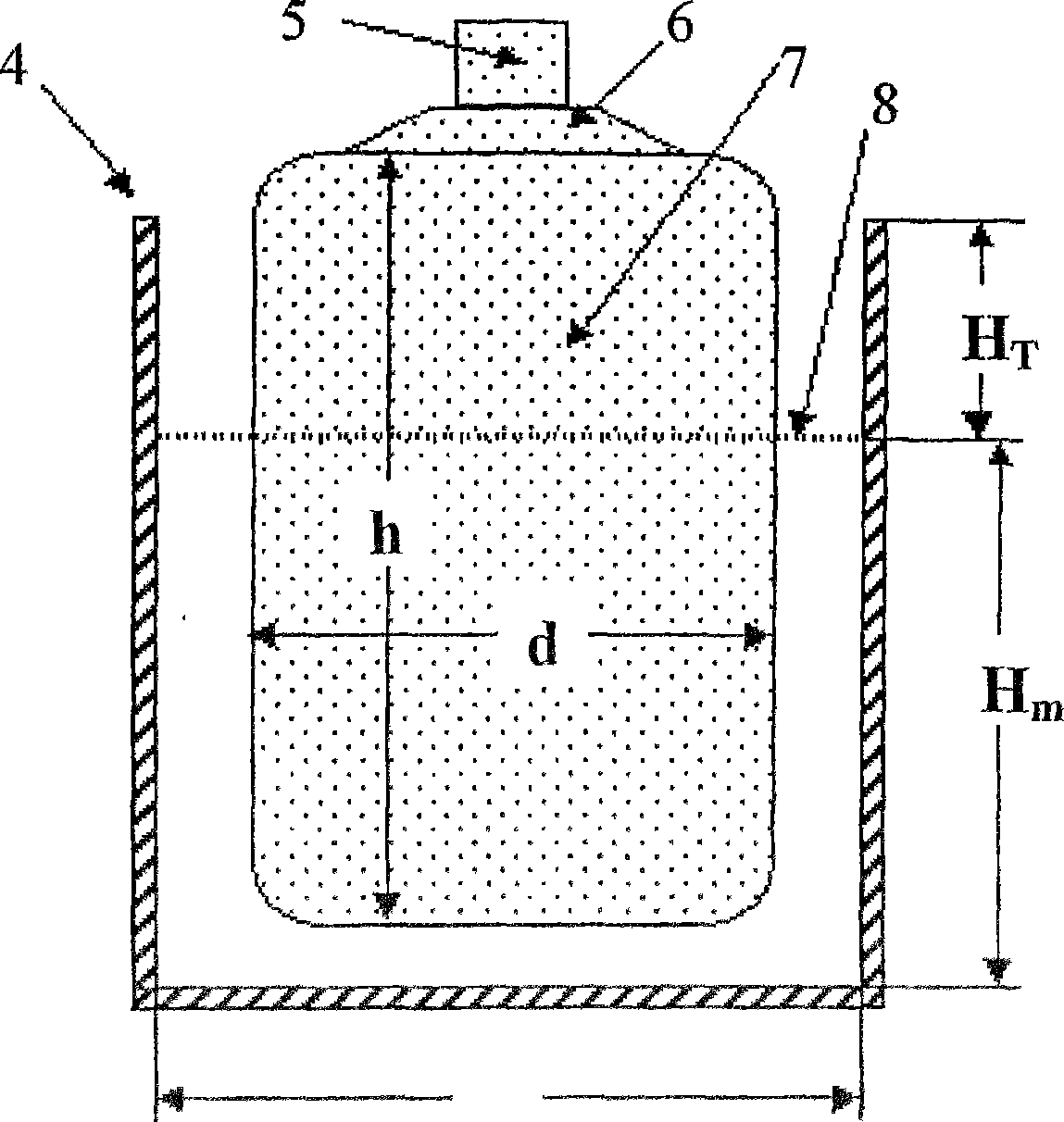

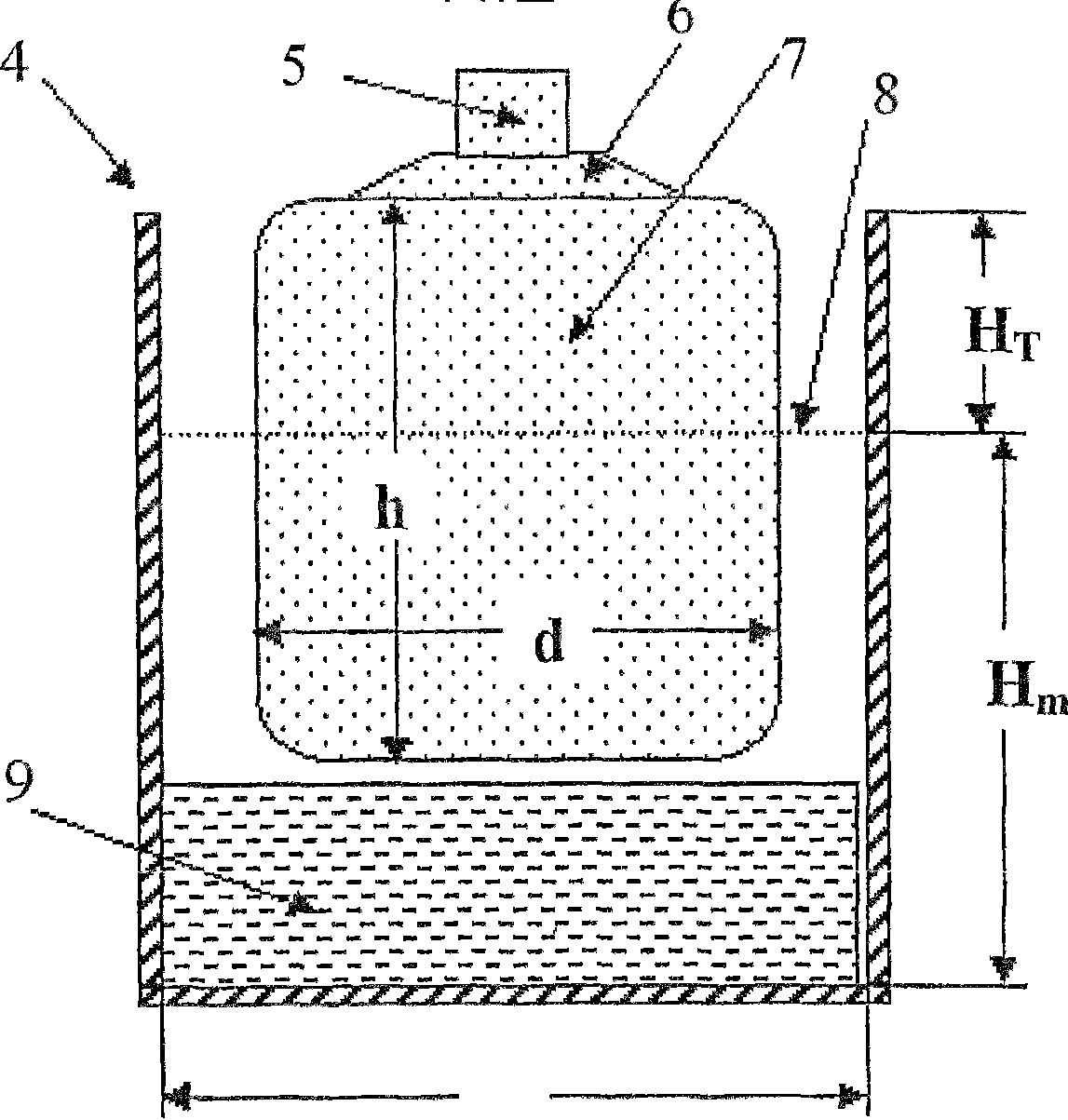

[0175] Growth of crystals with a diameter of 78 mm was performed from an iridium crucible with an inner diameter of 96 mm and a height of about 112 mm using a computer-controlled device equipped with a ...

Embodiment 3

[0181] Example 3. Method for the manufacture of scintillators in the form of scintillation ceramics based on lanthanum and lutetium oxidized orthosilicates, with the difference that Lu, La, Ce and SiCl are used 4 The aqueous chloride mixture mixture of liquid is used as feedstock for preparation (this feedstock has 51.9% (Lu 2 o 3 +La 2 o 3 +Ce 2 o 3 ) / 48.1%SiO 2 The oxide molar ratio is characteristic of the composition) of the raw materials. Aqueous ammonium carbonate solution was added to the mixture. The mixture was then filtered, drained and dried. After calcination at 1400°C, the resulting oxide mixture was stirred with added solvents and low-melting impurities, which facilitate the diffusion of atoms across grain boundaries during the final high-temperature anneal. Many compounds can be used as low melting point impurities and they do not affect the Ce 3+ emission of ions. Our studies show that small additions of Li, Na, K, Cs, Be, B, F, Al, S, Cl, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com