Synthesis method of rhein and Diacerein

A diacerein and cyclization technology, which is applied in the field of improved synthesis of antipyretic and analgesic drugs and intermediate chrysophanol, can solve the problems of high price of hydroiodic acid, difficulty in separation and purification, human and environmental pollution, etc., and achieve Improvement of purity and color, high product yield and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

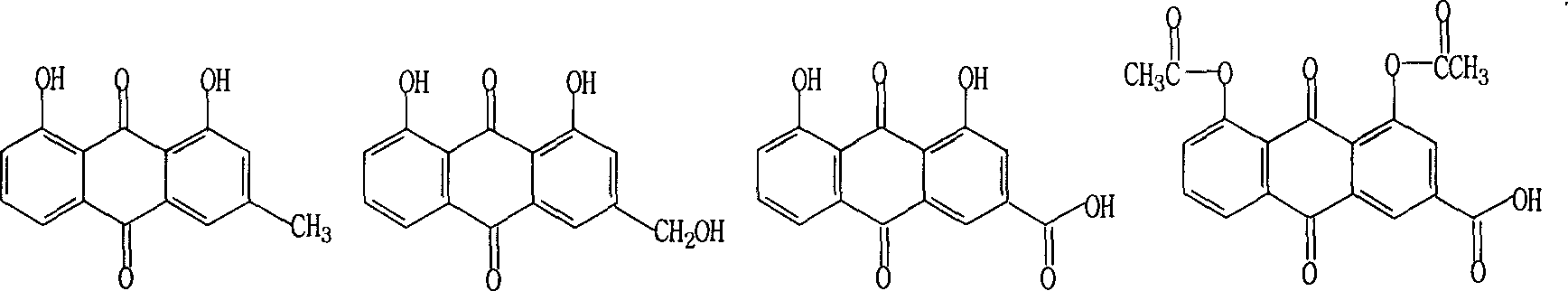

Image

Examples

Embodiment 1

[0022] Embodiment 1, the preparation of 2-(2-hydroxyl-4-methylbenzoyl)-3-nitrobenzoic acid

[0023] Weigh 96.6g (0.5mol) of 3-nitrophthalic anhydride and 400g (3.7mol) of m-cresol, and put them into a 2L three-necked flask equipped with a sealed stirrer, anhydrous calcium chloride drying tube and reflux condenser In the process, the flask was cooled in an ice-water bath, and 200g (1.5mol) of powdered anhydrous aluminum trichloride was added at one time, started to stir, heated up, heated to 100-110°C, and stirred vigorously for 3 hours until the release of hydrogen chloride stopped. A thick reddish-brown substance was produced. Ice was added while stirring until the excess chromium trichloride passed through the addition of 150ml of concentrated hydrochloric acid, the product coagulated and the solution was clarified. After filtration, the filter cake was treated with 50 g of sodium carbonate, filtered, and dried to obtain 107.8 g of white crystal 2-(2-hydroxy-4-methylbenzoyl...

Embodiment 2

[0024] Embodiment two, the preparation of 2-(2-hydroxyl-4-methylbenzoyl)-3-aminobenzoic acid

[0025] Put 301 g (1 mol) of 2-(2-hydroxy-4-methylbenzoyl)-3-nitrobenzoic acid, 300 ml of absolute ethanol and 5 g of Raney nickel or 10% palladium carbon into a 1 L autoclave. Close the autoclave, feed hydrogen, raise the temperature to 25°C to make the pressure 20-40Mpa, stir at a medium speed, rapidly raise the temperature to 90°C, stop heating, and maintain the reaction at 90-100°C for 8 hours. Cool, depressurize, and filter the catalyst. Ethanol was distilled off, and the residue was recrystallized to obtain 255 g of the amino compound, with a yield of 94.1%, mp: 225-226° C., and content (HPLC) ≥ 96.5%.

Embodiment 3

[0026] Example 3, Preparation of 1-hydroxyl-8-amino-3-methylanthraquinone

[0027] Put 27.1g (0.1mol) of 2-(2-hydroxy-4-methylbenzoyl)-3-aminobenzoic acid into a 500ml three-neck flask, add strong acid trifluoromethanesulfonic acid or concentrated sulfuric acid and stir to form a suspension , the mixture was heated to 150° C. for two hours, stirred at a constant speed, then the solution was cooled to room temperature, and neutralized with 10% NaOH aqueous solution.

[0028] The precipitate was filtered and evaporated to dryness to obtain a crystalline object, which was recrystallized with acetone and water to obtain about 18.8 g of dark red crystals, with a yield of 78.7%, mp: 245-246°C, and content (HPLC) ≥ 96.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com