Method of realizing microorganism in situ separation and fermentation employing inorganic film

An in-situ separation, inorganic membrane technology, applied in specific-purpose bioreactors/fermenters, biochemical equipment and methods, microorganisms, etc., can solve problems such as inability to separate target products or metabolic by-products, and achieve higher yields , Improve the growth rate, the effect of high-density culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Production of vitamin B by P. shermanii 12 in situ separation fermentation

[0026] Propionic acid, the main primary metabolite in the submerged fermentation process of P.shermanii, has a serious inhibitory effect on bacterial growth, while vitamin B 12 It is the intracellular secondary metabolite of P.shermanii, so timely remove propionic acid from the fermentation system, relieve the inhibitory effect of propionic acid on the bacteria, and achieve high-density culture will greatly increase the vitamin B 12 output.

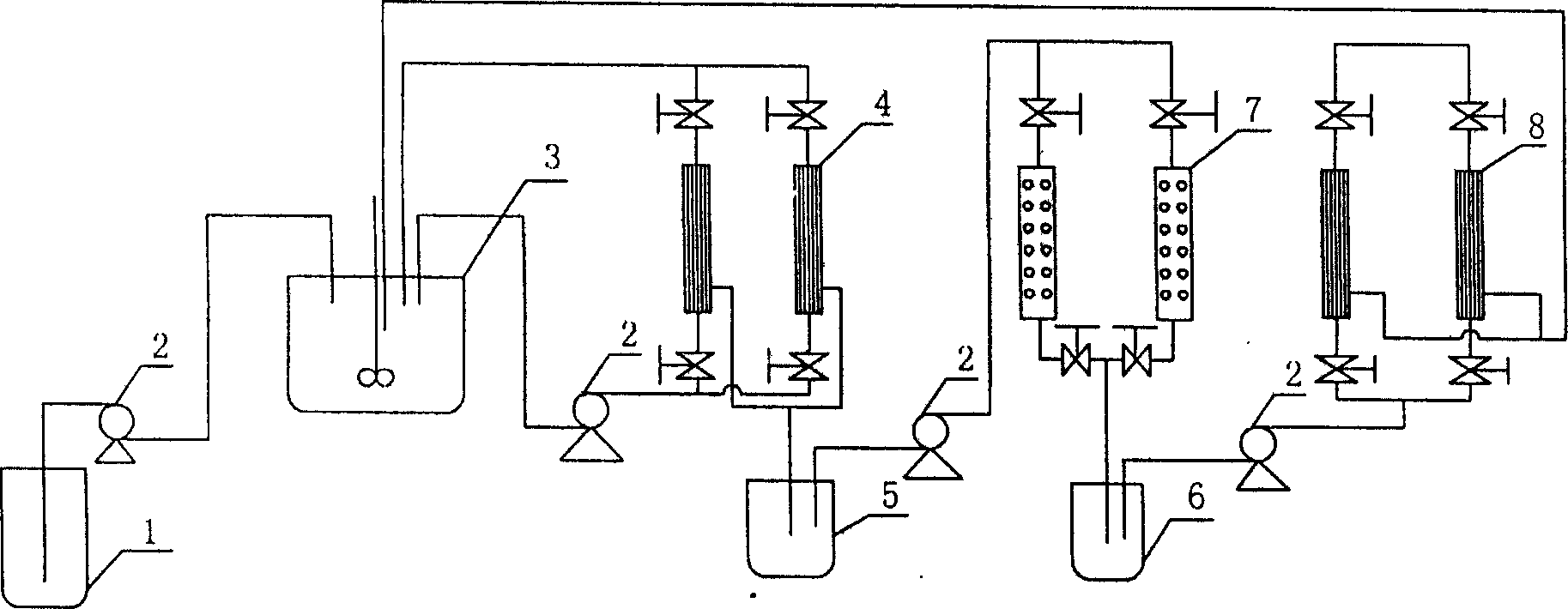

[0027] The in-situ separation fermentation reactor is mainly composed of a fermenter 3, an inorganic membrane module 4 and 8, a chromatographic column 7, a feeding tank 1, a liquid storage tank 5 and 6, and a peristaltic pump 2, wherein the inorganic membrane module includes two groups, The first group of inorganic membrane modules, i.e. inorganic membrane modules 4, are used to filter metabolites that are unfavorable to the growth of bacteria...

Embodiment 2

[0047] In Situ Isolation and Culture of Bacillus cogulans TQ33

[0048] The lactic acid produced during the fermentation of Bacillus coagulans has a strong inhibitory effect on the growth of the bacteria, so the timely separation of the lactic acid from the fermentation broth will greatly increase the concentration of the bacteria and spores. The 7L fermenter used in the experiment was purchased from Shanghai Gaoji Company, and the inorganic ceramic membrane module was purchased from Anhui Shijie Membrane Engineering Co., Ltd., with a pore size of 0.2 μm. Anion exchange resin D354 was purchased from Hangzhou Zhengguang Resin Co., Ltd.

[0049] 1: culture medium

[0050] (1) Seed medium (g / L)

[0051] Peptone 10.0, yeast extract 10.0, glucose 60.0, MgSO 4 ·7H 2 O 0.5, CaCO 3 10.0. pH7.2-7.4.

[0052] (2) Fermentation medium (g / L)

[0053] Peptone 10.0, yeast extract 10.0, glucose 6.0, MgSO 4 ·7H 2 O 1.0, K 2 HPO 4 2.0, MnSO 4 50mg / L pH 7.0.

[0054] (3) GYP med...

Embodiment 3

[0065] In Situ Separation and Fermentation of Exopolysaccharides Produced by Schizophyllum

[0066] Schizophyllum exopolysaccharide is a water-soluble β-D-glucan, because of its good water solubility and the unique properties of β-(1-3)-D glucose with β-(1-6) branches The active structure has remarkable curative effects in regulating immune function, anti-tumor, anti-radiation and so on. The exopolysaccharide molecular weight of Schizophyllum is about 40kD. The accumulation of exopolysaccharides from Schizophyllum in the fermentation broth increases the viscosity of the fermentation broth, which is not conducive to the growth of bacteria, so the timely separation of polysaccharides can help increase the yield of exopolysaccharides.

[0067] The 7L fermenter used in the experiment was purchased from Shanghai Gaoji Company, and the inorganic stainless steel membrane module was purchased from Shanghai Kaineng High-tech Engineering Co., Ltd., with a pore size of 0.2 μm. Macropor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com