Rare earth elements doped sealing by fusing glass powder without lead, and manufacturing method

A technology of rare earth elements and manufacturing methods, which is applied in the field of sealing materials and lead-free low-melting glass powder, can solve the problems of difficult preparation, high working temperature of sealing glass powder, poor chemical stability, etc., to reduce the expansion coefficient, process and manufacture The process is simple and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

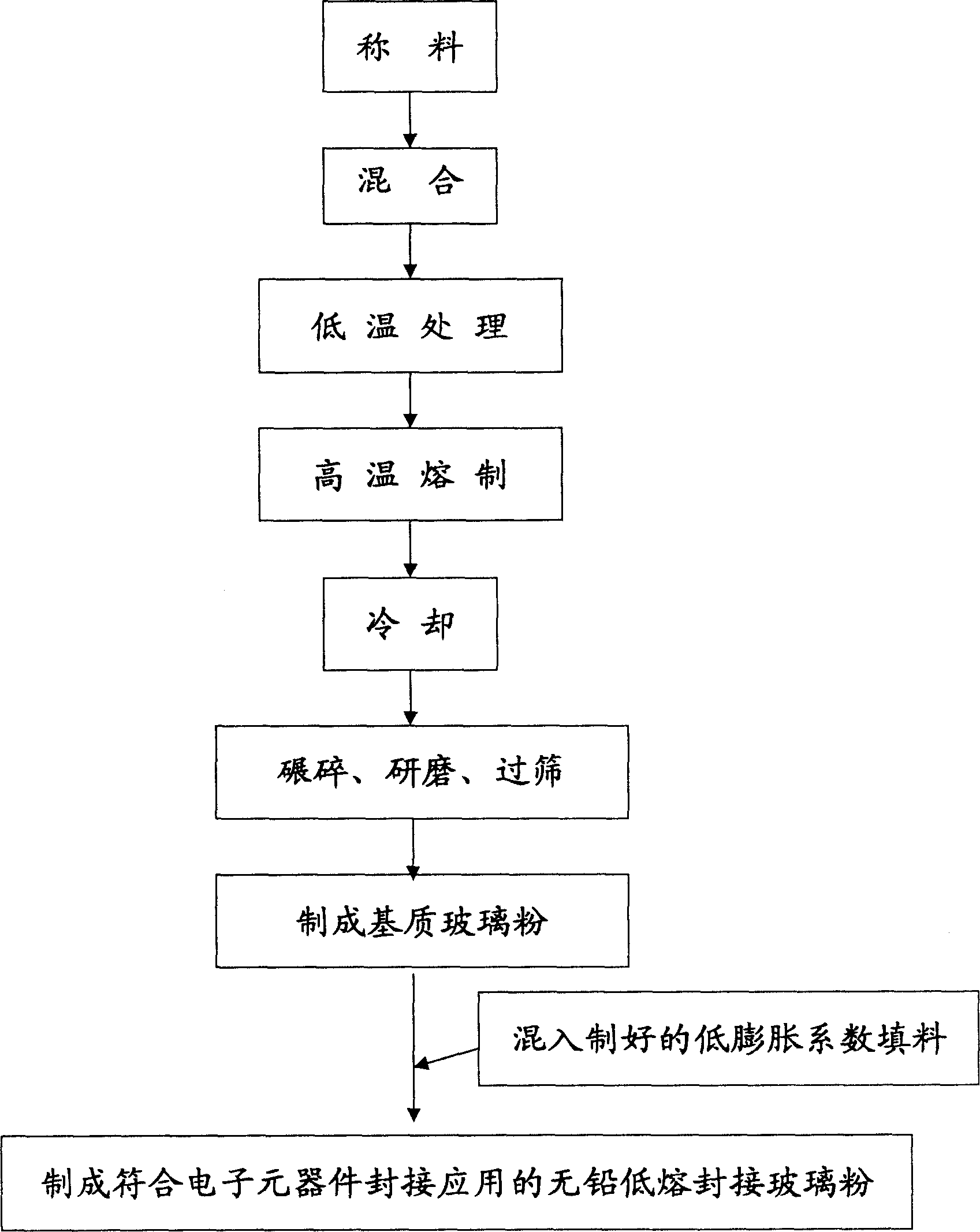

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Calculate and select raw materials according to the composition of Example 1 in Table 1, weigh 30 grams of vanadium pentoxide, 10 grams of phosphorus pentoxide, 8 grams of antimony trioxide, 30.6 grams of lithium carbonate, 25.7 grams of soda ash, and potassium carbonate 14.8 grams, 10 grams of magnesium oxide, 14.4 grams of calcium carbonate, 3.5 grams of strontium chloride, 16.0 grams of barium chloride, 8.5 grams of zinc oxide, 10 grams of tin (II) oxide, 44.9 grams of boric acid, 5 grams of aluminum oxide, trioxide 3 grams of bismuth, 8 grams of ferric oxide, 8 grams of silicon dioxide, 2 grams of tin (IV) oxide, 5 grams of lanthanum oxide, 0.001 grams of cerium oxide, 8 grams of yttrium oxide and 6 grams of neodymium oxide.

[0034] Step 2: Mix the above-mentioned weighed raw materials evenly, and dry them at 280° C., grind and pulverize them after processing, and mix 0.3 g of carbon powder as a reducing agent (0.1-0.3 wt% of the raw materials in step 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com