Indium oxide/cerium oxide sputtering target, transparent conductive film and process for producing transparent conductive film

一种透明导电膜、氧化铈的技术,应用在溅射靶领域,能够解决难以使用、细化、Al配线断线等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

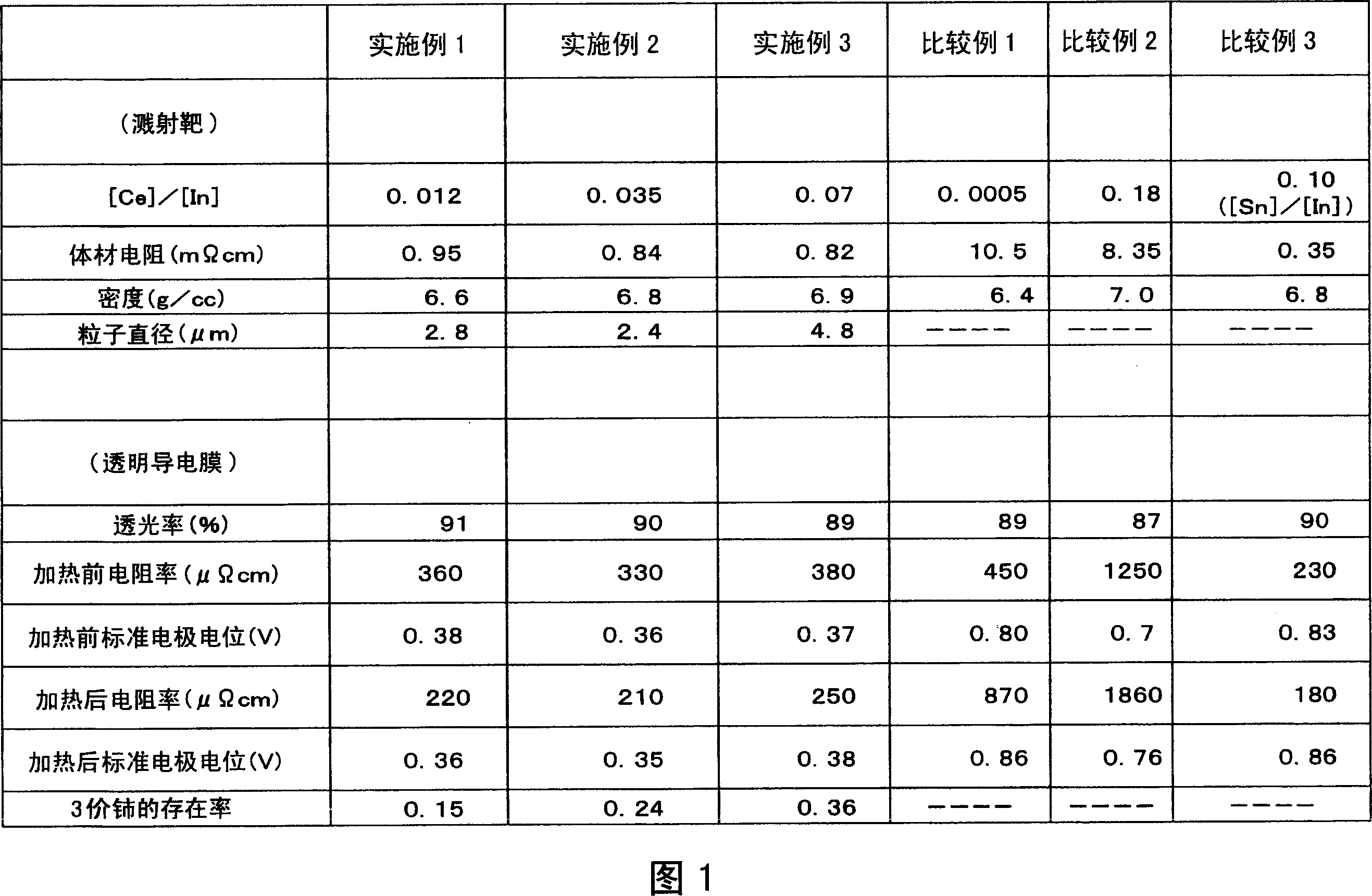

Embodiment 1

[0091] In the average particle size below 1μm 2 o 3 Powder and CeO with an average particle size below 1 μm 2 The powder was blended so that the atomic number ratio of cerium / indium reached 0.012, and it was added to a resin pot, and pure water was added to conduct a test using hard ZrO 2 Ball mill for wet ball mill mixing. The mixing time was set to 20 hours.

[0092] As a result of the mixing, the obtained mixed slurry was taken out, filtered, dried and granulated. Apply 294MPa (3t / cm 2 ) pressure, using a low-temperature static pressure press to form.

[0093] Then, the molded body was sintered as shown below.

[0094] First, in the sintering furnace, form a furnace volume per 0.1m 3An atmosphere of oxygen was introduced at a rate of 5 L / min. Sintering was carried out at 1450° C. for 8 hours in this atmosphere. At this time, the temperature was raised to 1000°C at 1°C / min, and at 2°C / min for 1000 to 1450°C. Thereafter, oxygen introduction was stopped, and the temp...

Embodiment 2

[0106] In this Example 2, except that the ratio of the number of atoms of cerium and indium per unit volume and unit mass ((number of cerium atoms) / (number of indium atoms)) was adjusted to 0.035, the same method was carried out. The same processing and operation as described in Example 1.

[0107] As a result of this treatment, cerium-containing In with a bulk resistance of 0.84 mΩcm and a density of 6.8 g / cc or higher was obtained. 2 o 3 Sintered body. The presence of cerium oxide in the sintered body can be confirmed by X-ray diffraction. In addition, the particle size of cerium oxide existing as a single substance can be confirmed by EPMA. Since it is contained in such a dispersed manner, the diameter of the crystal particles is 2.4 μm. This diameter is obtained by image processing. Using this sputtering target, a transparent thin film with a thickness of 70 nm was formed.

[0108] When the light transmittance with respect to the light of wavelength 550nm of the glas...

Embodiment 3

[0115] In this Example 3, in addition to adjusting the ratio of the number of atoms of cerium and indium per unit volume and unit mass ((number of cerium atoms) / (number of indium atoms)) to a ratio of 0.07, the same method was carried out. The same processing and operation as described in Example 1.

[0116] As a result of this treatment, cerium-containing In with a bulk resistance of 0.82 mΩcm and a density of 6.9 g / cc or higher was obtained. 2 o 3 Sintered body. The presence of cerium oxide in the sintered body can be confirmed by X-ray diffraction. In addition, the particle size of cerium oxide existing as a single substance can be confirmed by EPMA. Since it is contained in such a dispersed manner, the diameter of the crystal particles is 4.8 μm. This diameter is obtained by image processing. Using this sputtering target, a transparent thin film with a thickness of 70 nm was formed.

[0117] When the light transmittance with respect to the light of wavelength 550nm o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com