Low temperature beta-galactosidase strain, low temperature bata-galactosidase and its production process

A technology of galactosidase and production process, which is applied in the field of low-temperature β-galactosidase and its production process, and can solve problems such as difficulty in meeting market and production needs, low enzyme activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

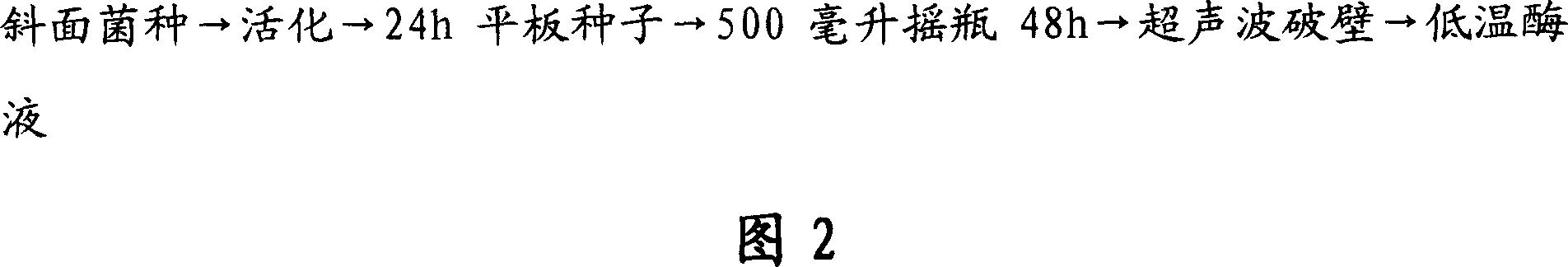

[0037] Embodiment 1: Preservation and rejuvenation of bacterial strain L2004

[0038] A strain of low-temperature lactase-producing bacteria L2004 was isolated from the cold storage of Urumqi Meat Union Factory. It was identified as Bacillus brevius. The optimal reaction temperature of the low-temperature lactase produced was 33°C, and the half-life of the enzyme was about 50 minutes at 40°C.

[0039] Two methods were used for strain preservation, that is, liquid paraffin preservation method and vacuum freeze-drying method. The former is used for short-term preservation of strains (3-6 months), and the latter is used for long-term preservation of strains produced (6 months-several years).

[0040] Activation of preserved strains: take the preserved strains, use an inoculation needle to pick out the strains and inoculate them into a test tube filled with 2 ml of sterile water, and shake for 10 minutes. Then use a sterile pipette to take 0.2 ml and add it to the slant medium TS...

Embodiment 2

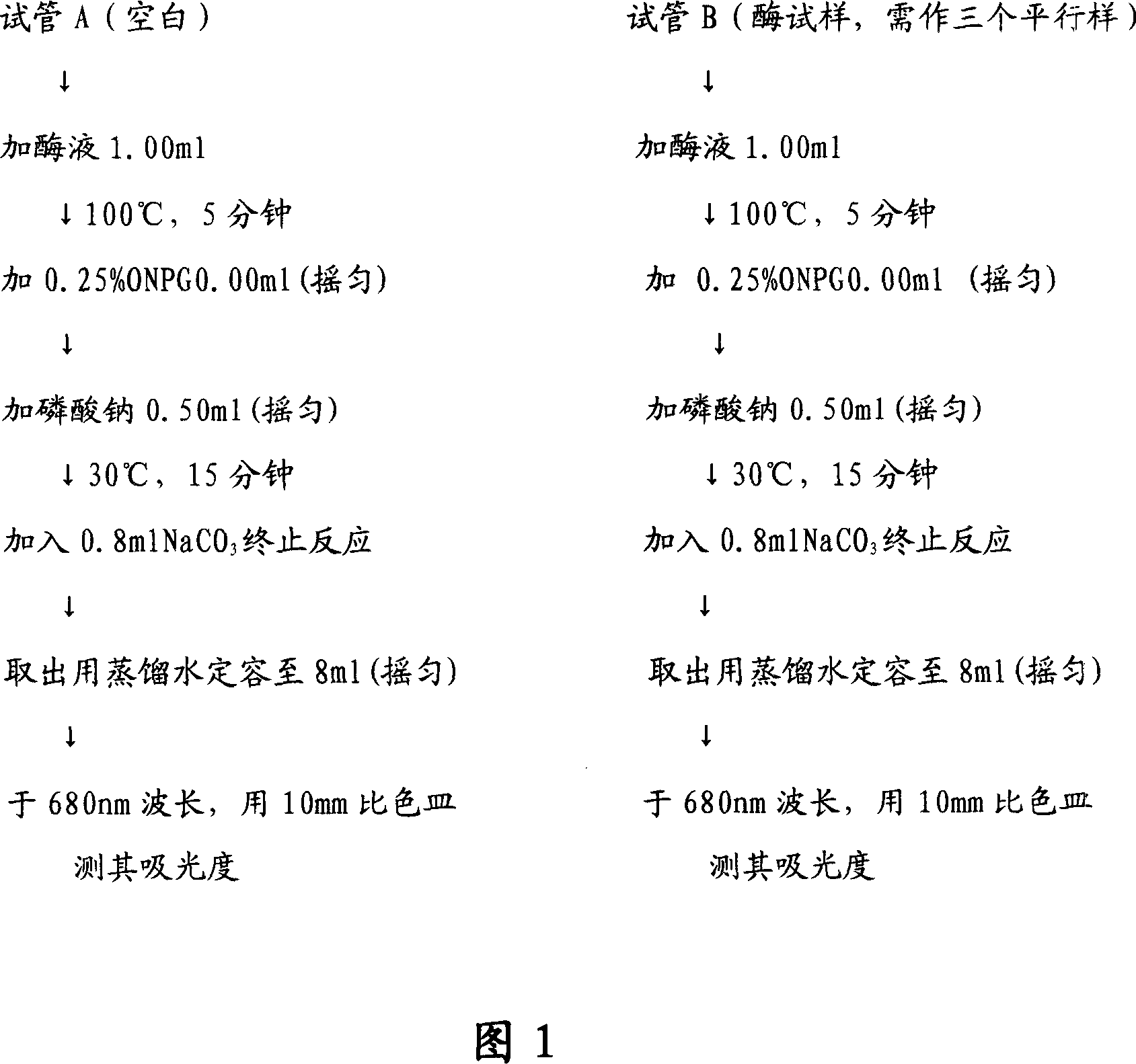

[0043] Example 2: Detection method for low temperature lactase activity of bacterial strain L2004

[0044] Use ONPG as the substrate for determination, take 1ml of enzyme solution in a test tube and preheat it in a 30°C water bath for 10 minutes, add 0.5mL pH6.5 0.1mol / L sodium phosphate buffer solution (1mol / L NaH 2 PO 4 70mL with 1mol / L Na 2 HPO 4 30mL buffer solution was mixed and diluted 10 times) and 0.2mL ONPG solution (pH6.5. 0.1mol / L sodium phosphate preparation) was reacted for 5min, and 0.8ml 5% Na 2 CO 3 Solution to stop the enzyme reaction, measure OD 420nm value. Under the above conditions, the amount of enzyme that hydrolyzes ONPG to generate 1 μmol o-nitrophenol per minute is 1 ONPG enzyme activity unit.

[0045] 1. Definition

[0046] 1 gram of solid enzyme powder (or 1ml of liquid enzyme), under certain temperature and pH conditions, hydrolyzes ONPG (o-nitrophenol galactoside) for 1 minute to produce 1umol tyrosine as an enzyme activity unit, expresse...

Embodiment 3

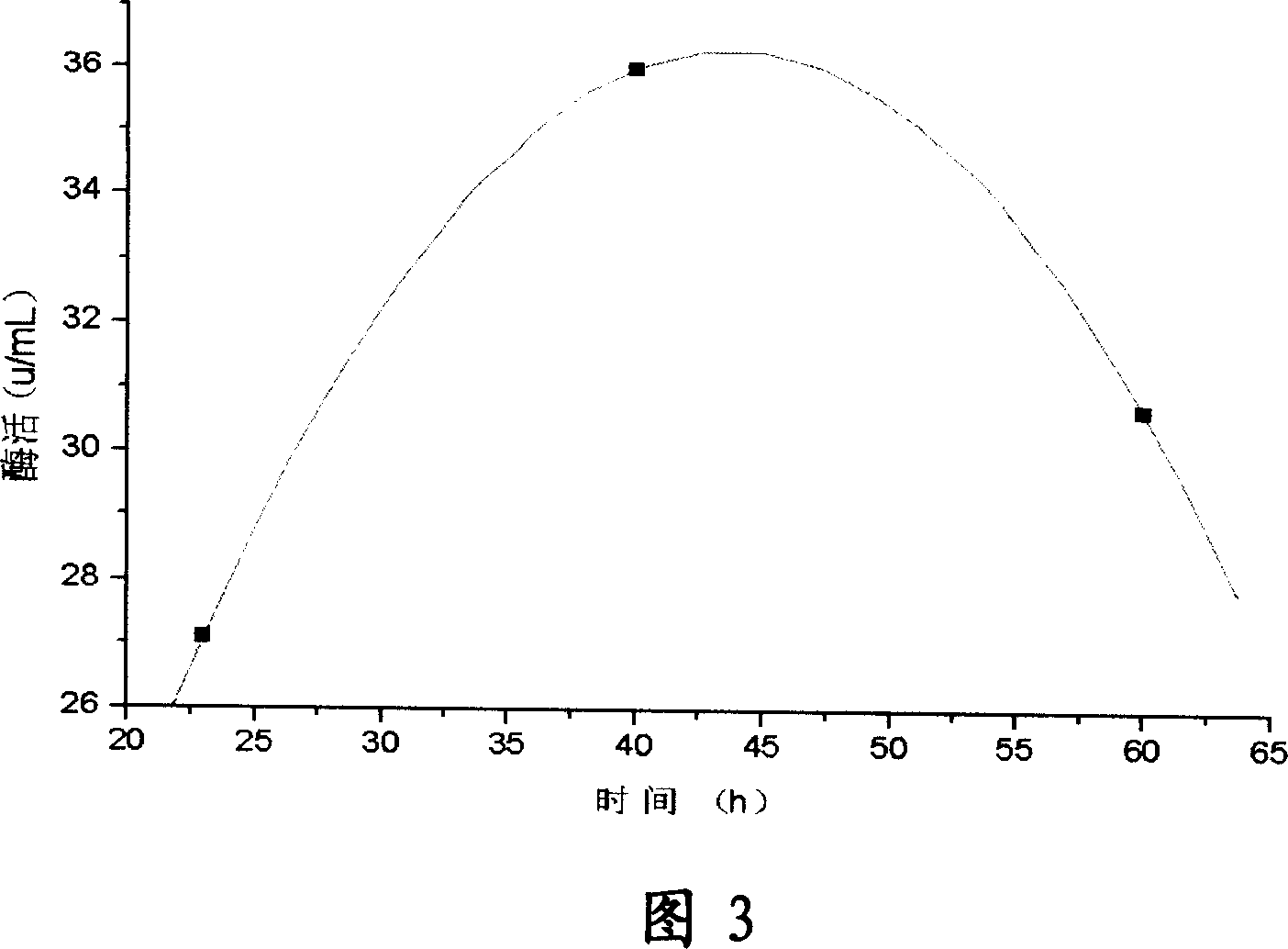

[0084] Embodiment 3: the measurement of the temperature characteristics of the bacterial strain of the present invention and its enzyme production

[0085] Medium: tryptone 15g, soybean peptone 5g, sodium chloride 5g, lactose 2.5g, dipotassium hydrogen phosphate 2.5g, water 1000ml, pH6.5.

[0086] At 4°C, 20°C, 42°C, 200 rpm, 60ml material / bottle (500ml shake flask), add cotton plug, culture time 6d, 2d, 1d respectively, take 5ml culture suspension in 50ml centrifuge tube , using a sonicator (broken wall) in an ice-water bath. Break the wall for 5 minutes at an intensity of 10 to release the enzyme from the cells. Take it out with a spectrophotometer at a wavelength of 420nm and a 10mm cuvette, and use a tube that does not meet ONP as a blank, and measure its absorbance respectively. At the same time, use a spectrophotometer at a wavelength of 620nm and a 10mm cuvette to measure the absorbance of the tube without inoculated culture medium as a blank.

[0087] The results sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com