Carbon-coated magnetic superfine iron particle and its manufacturing method

A carbon coating and magnetic technology, applied in the direction of coating, can solve the problems of harsh reaction conditions, difficult to prepare in large quantities, and high raw material requirements, and achieve the effect of small particle size, low raw material requirements, and high saturation magnetization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

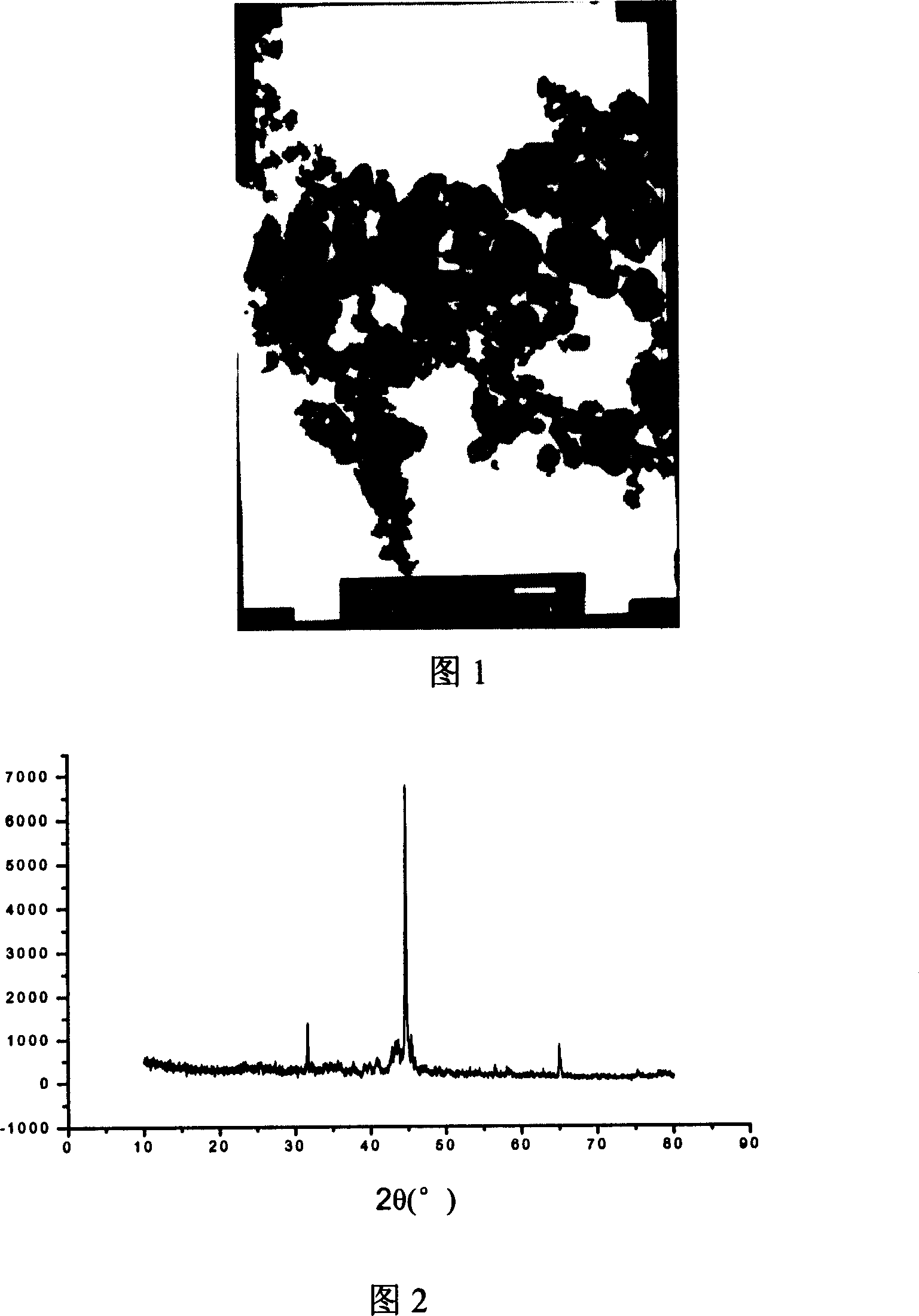

[0031] Take 5g of sodium chloride and 5g of ferric oxide with an average particle diameter of 10nm, add 80g of steel balls with a diameter of 6mm and dry mill for 24 hours at a speed of 300 rev / min, weigh 1g of sodium chloride after ball milling and The mixture of ferroferric oxide is spread on the bottom of the ark, and placed in the constant temperature zone of the tubular reactor. The outlet of the reactor is at normal pressure. After 30 minutes of hydrogen flow at a flow rate of 30ml / min, the temperature starts to rise, and the heating rate is 20°C / min. , control the temperature at 600°C, and perform the reduction reaction for 2 hours. Adjust the flow rate of hydrogen to 5ml / min to lower the temperature to 450°C, inject 100ml / min of nitrogen and 10ml / min of acetylene, coat the reaction for 30min, turn off nitrogen and acetylene, and drop to room temperature under the protection of hydrogen, and the product is used up Washing with ion water (until silver nitrate is added to...

Embodiment 2

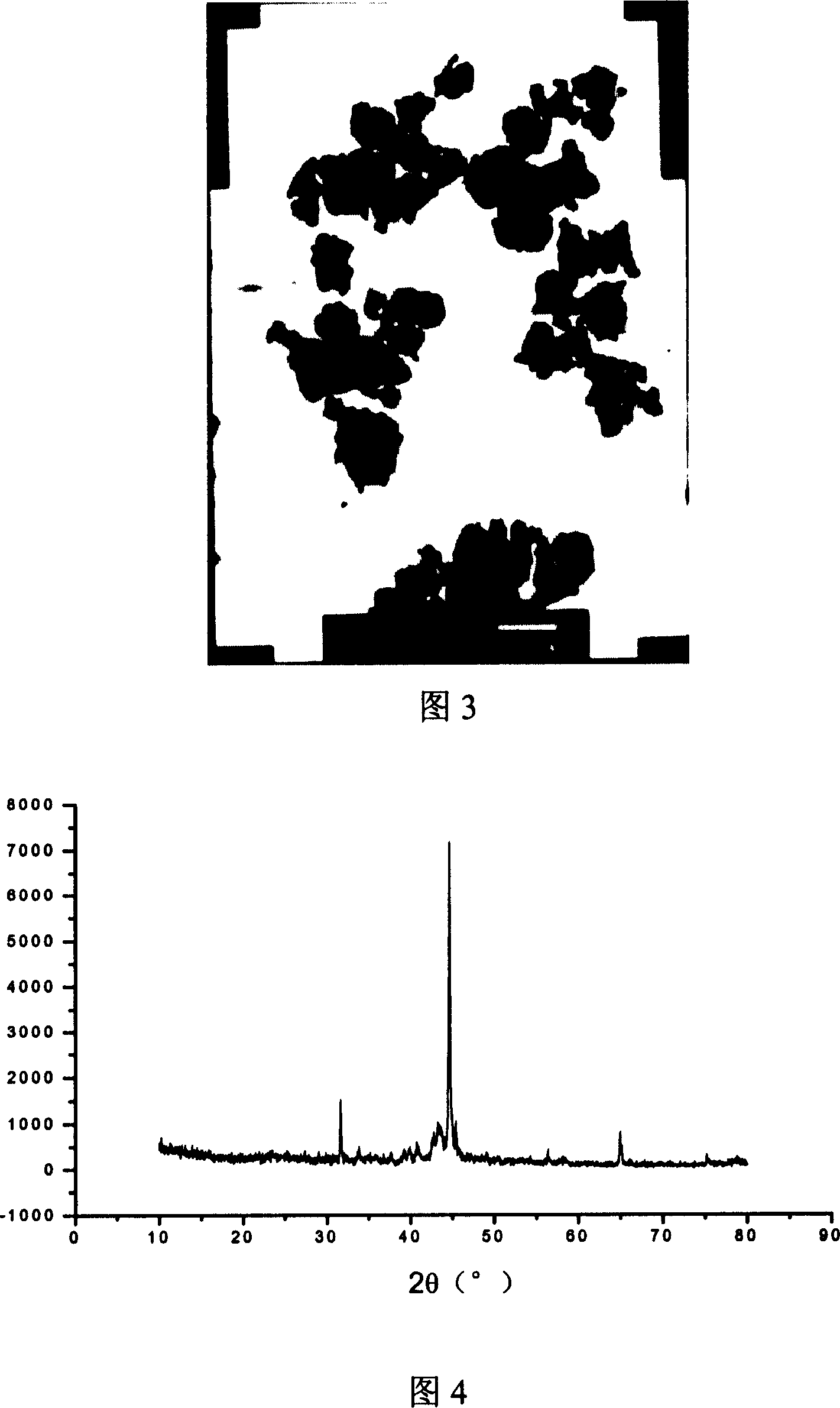

[0034] Ball milling and reduction are the same as in Example 1, except that the reduction reaction temperature is 500° C., and the spacer is potassium chloride; the carbon coating reaction conditions are the same as in Example 1, except that the carbon source acetylene is changed to 50% each of ethanol and acetylene ( Volume ratio).

[0035] According to electron microscope analysis, the product is granular (see Figure 3), and the particle size of the product is mainly 20-300nm; the specific saturation magnetic strength is 143emu / g and the residual magnetization is 1.37emu / g when the vibrating sample magnetometer is tested. After one month, the test specific saturation magnetization is 139emu / g; the thermogravimetric balance (TG) analysis test shows that its oxidation resistance temperature is 420°C; the X-ray diffraction test (see accompanying drawing 4) shows that iron exists in the α-Fe phase in the product, containing Trace amounts of iron sulfide and iron oxide, in which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com