Synthetic method for silicon dioxide hollow bal lincluding noble metal nano particles

A silica and nanoparticle technology, applied in the direction of coating, can solve the problems of non-adjustment, difficult application, single function of shell macromolecule, etc., and achieve the effect of good mechanical properties and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

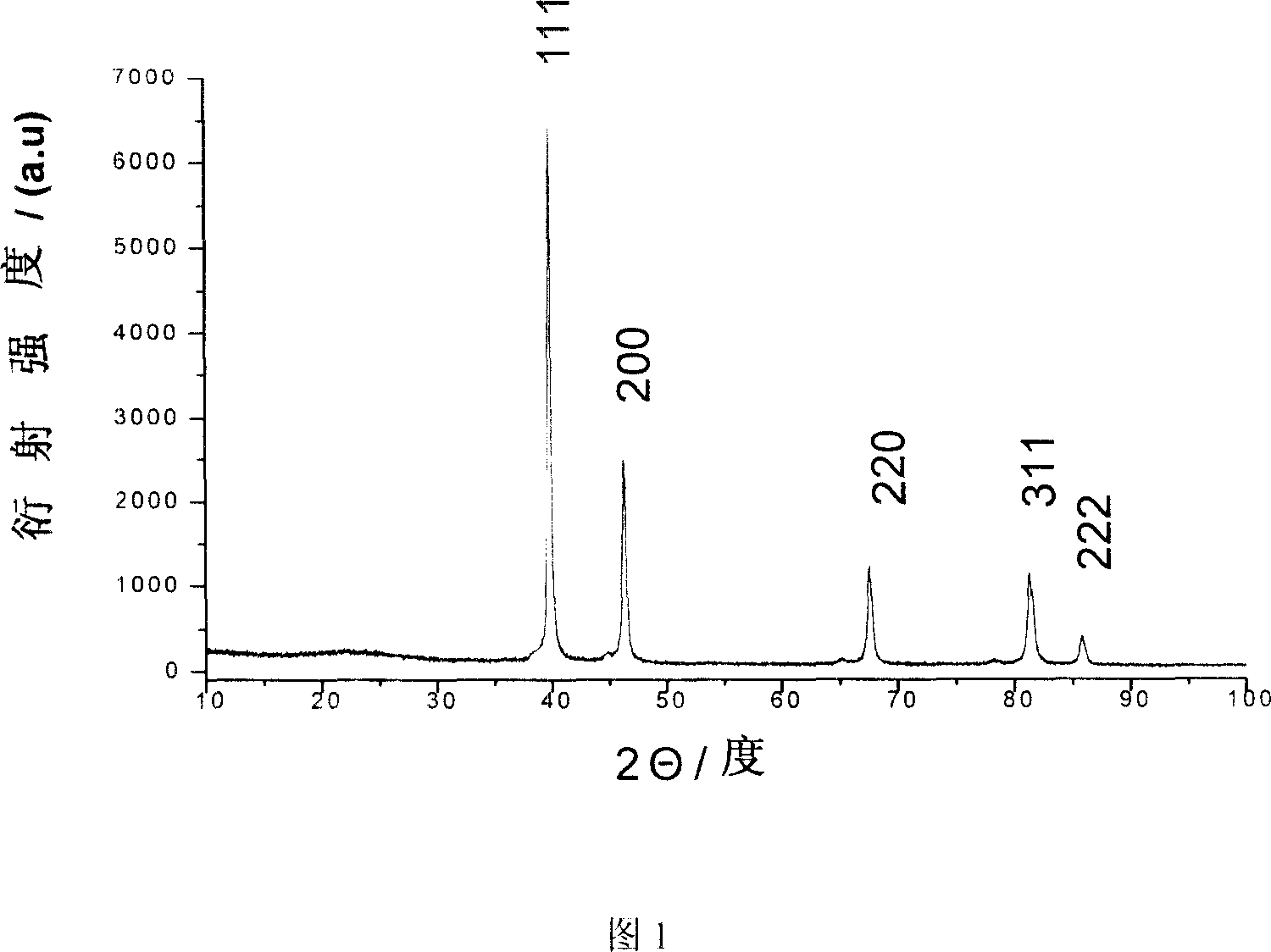

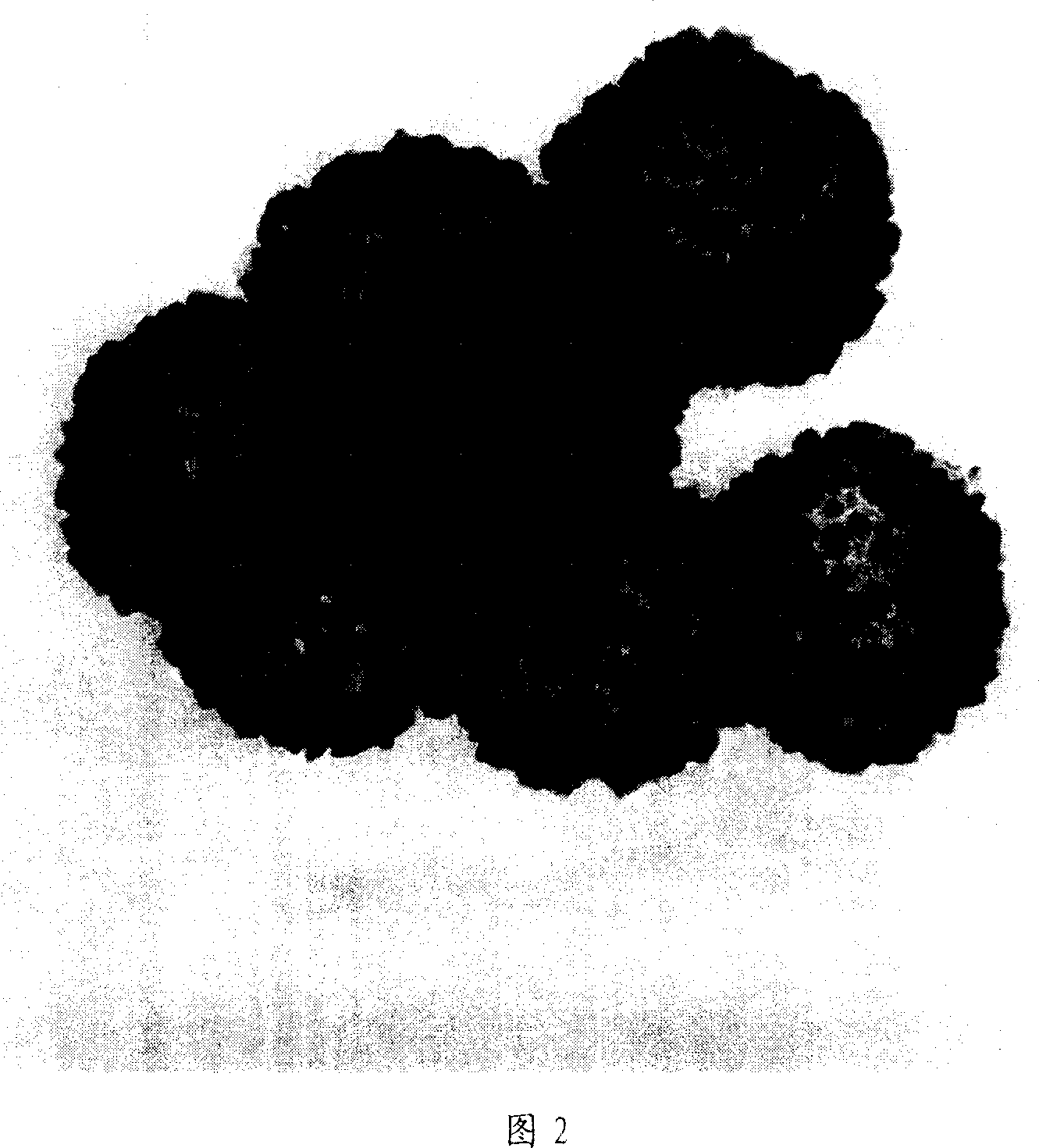

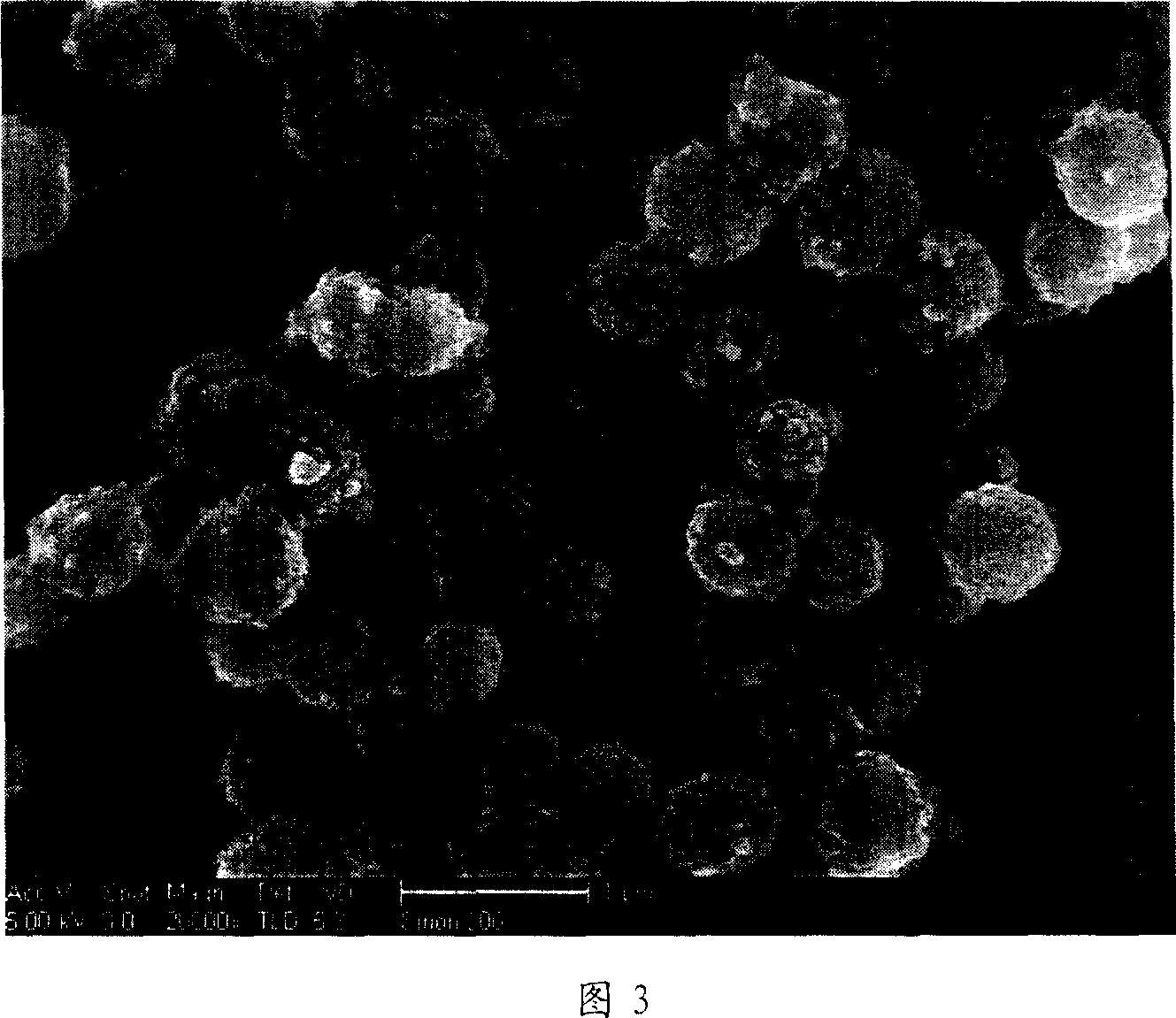

[0022] Example 1: Preparation of hollow silica spheres containing both gold and platinum particles with a shell thickness of 80 nm:

[0023] Dissolve 0.02 g of glucose in 30 ml of water, stir for 15 minutes, add dropwise 200 microliters of chloroauric acid aqueous solution with a concentration of 0.01 mol / L, stir for another 10 minutes, and transfer 31 ml of the above solution to a polytetrafluoroethylene-lined, In an autoclave with a volume of 45 ml, the reaction was carried out at 160°C for 20 hours, and the obtained product was washed by centrifugation for three times and then dried.

[0024] A total of 0.05 grams of carbon spheres containing gold cores prepared according to the aforementioned method were dispersed in 50 milliliters of distilled water, mixed with 1.5 milliliters of 12.5 mg / L chloroplatinic acid aqueous solution, refluxed in an oil bath at 160 ° C for 3 hours, and centrifuged Wash with water and ethanol three times respectively, then disperse into 40 ml of a...

Embodiment 2

[0033] Example 2: Preparation of hollow silica spheres containing gold and platinum particles with a shell thickness of 40 nm:

[0034] The carbon source is glucose as an example, 0.2 gram of glucose is dissolved in 30 milliliters of water, after stirring for 15 minutes, 2 milliliters of chloroauric acid with a concentration of 0.2 mol / liter is added dropwise, and then stirred for 10 minutes, then 31 milliliters of the above solution is transferred to the In a tetrafluoroethylene-lined autoclave with a volume of 45 ml, react at 180° C. for 16 hours, and the product is washed by centrifugation for three times and then dried.

[0035] Disperse 0.1 g of carbon spheres containing gold cores prepared according to the aforementioned method in 50 ml of distilled water, mix them with 10 ml of 0.01 mol / L chloroplatinic acid aqueous solution, reflux in an oil bath at 100°C for 10 hours, and centrifuge After washing with water and ethanol three times, disperse into 60 ml of aqueous solut...

Embodiment 3

[0038] Example 3: Preparation of hollow silica spheres containing gold and palladium particles with a shell thickness of 40 nm:

[0039]Glucose is used as the carbon source in this example, 0.3 g of glucose is dissolved in 30 ml of water, after stirring for 15 minutes, 5 ml of chloroauric acid with a concentration of 0.4 mol / L is added dropwise, stirred for another 10 minutes, and then 31 ml of the above solution is transferred In an autoclave with a volume of 45 ml and a polytetrafluoroethylene liner, react at 200° C. for 4 hours, and the product is washed by centrifugation three times and then dried.

[0040] Disperse 0.125 grams of carbon spheres containing gold cores prepared according to the aforementioned method in 50 milliliters of distilled water, mix them with 2 milliliters of palladium chloride aqueous solution with a concentration of 0.5 mol / liter, reflux in an oil bath at 140 ° C for 5 hours, and centrifuge After washing with water and ethanol for three times, disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com