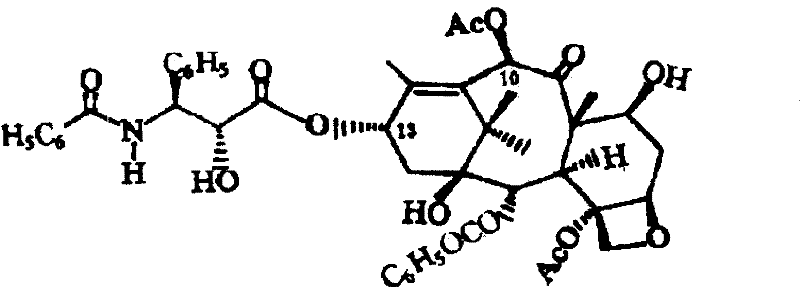

A kind of preparation method of high-purity paclitaxel compound

A technology for paclitaxel and compounds, which is applied in the field of preparation of high-purity paclitaxel compounds, can solve the problems of large consumption of chromatographic fillers, high production cost, large workload and the like, and achieves the effects of peak shape resolution, simple operation and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

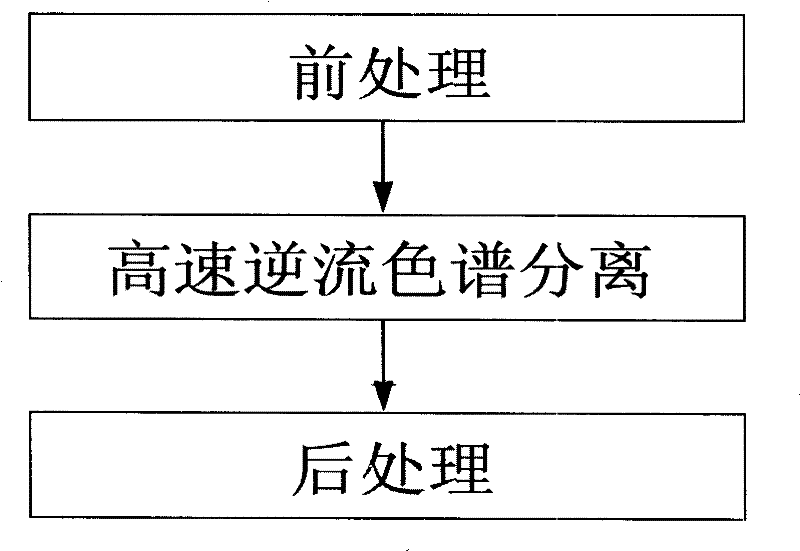

Method used

Image

Examples

Embodiment 1

[0027] A high-speed countercurrent chromatography system with a column volume of 300ml was used for separation (equipped with NS-1007 pump, 8823A-UV ultraviolet detector and Yokogawa3057 portable recorder). Select n-hexane-ethyl acetate-acetone-water as the solvent system, arrange the above-mentioned solvent components in a separatory funnel according to the volume ratio of 7:3:5:5, shake well, and then let stand to separate layers. After equilibrating for a period of time, separate the upper phase (stationary phase) and the lower phase (mobile phase).

[0028] Weigh 200mg of paclitaxel crude extract, heat and dissolve with 20ml of stationary phase for later use. Before sample injection, fill the entire column with stationary phase, adjust the speed of the main engine, pump the mobile phase into the column until a dynamic balance is established, and inject samples through the injection valve; then receive the target components according to the detection spectrum. After the ta...

Embodiment 2

[0030] A high-speed countercurrent chromatography system with a column volume of 1000ml was used for separation. Petroleum ether-chloroform-methanol-water was selected as the solvent system, and the above solvent components were arranged in a separatory funnel according to the volume ratio of 3:7:3:5, shaken up and then allowed to stand for stratification. After equilibrating for a period of time, separate the upper phase (stationary phase) and the lower phase (mobile phase).

[0031] Weigh 1g of paclitaxel crude extract, heat and dissolve with 50ml of stationary phase for later use. Before sample injection, fill the entire column with stationary phase, adjust the speed of the main engine, pump the mobile phase into the column until a dynamic balance is established, and inject samples through the injection valve; then receive the target components according to the detection spectrum. After the target fraction is evaporated to dryness, it can be crystallized with methanol to o...

Embodiment 3

[0033] A high-speed countercurrent chromatographic system with a column volume of 5000ml was used for separation. Petroleum ether-diethyl ether-ethanol-water was selected as the solvent system, and the above-mentioned solvent components were arranged in a separatory funnel according to the volume ratio of 70:70:30:70, and the mixture was left to stand and separate after shaking. After equilibrating for a period of time, separate the upper phase (stationary phase) and the lower phase (mobile phase).

[0034] Weigh 5g of paclitaxel crude extract, heat and dissolve with 250ml stationary phase for later use. Before sample injection, fill the entire column with stationary phase, adjust the speed of the main engine, pump the mobile phase into the column until a dynamic balance is established, and inject samples through the injection valve; then receive the target components according to the detection spectrum. After the target fraction is evaporated to dryness, it can be crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com