Pt-supported tungsten carbide catalyst and preparation method thereof

A technology of platinum catalyst and tungsten carbide, which is applied in the field of preparation of tungsten carbide-supported platinum catalyst, can solve the problems that have not yet been seen in literature and application reports, and achieve the effect of simple process and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

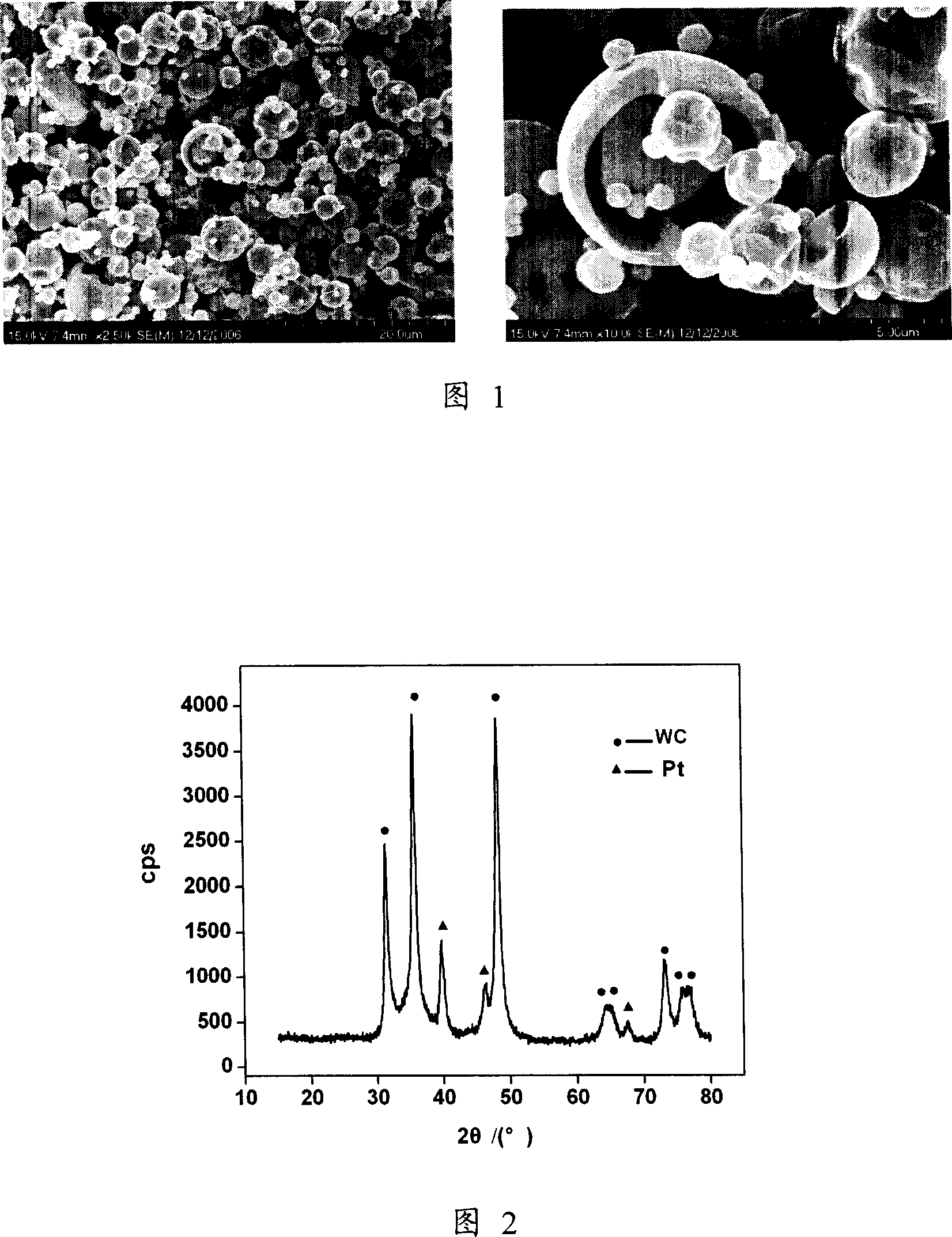

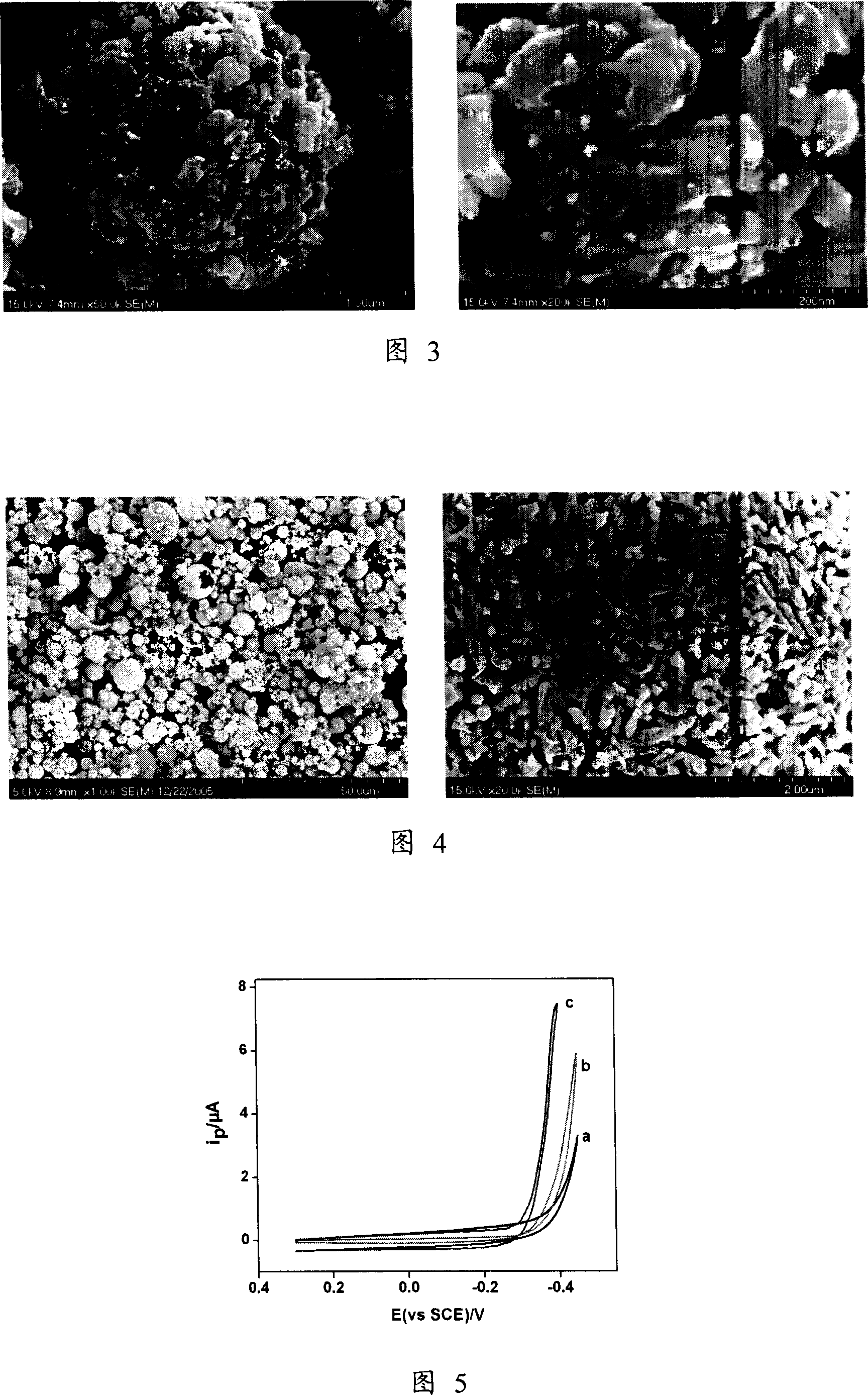

Embodiment 1

[0033] Ammonium metatungstate (AMT, (NH 4 ) 2 W 4 o 13 ·5H 2 O) and chloroplatinic acid (H 2 PtCl 6 ) is mixed in distilled water according to the mass ratio of raw materials of 1:0.23, and is prepared into a mixed aqueous solution, wherein the mass concentration of ammonium metatungstate in the solution is 5wt%, and is ultrasonically oscillated at room temperature for 30 minutes, and then stirred by a magnetic stirrer The solution was introduced into a spray dryer for spray drying to obtain hollow spherical H 2 WO 3 / Chloroplatinic acid microsphere particle precursor; put the granulated and dried precursor into a quartz boat and place it in a tubular resistance furnace, inject hydrogen at 400°C, perform a 2-hour roasting heat treatment, and then raise the temperature To 900°C, the mixed gas of methane and hydrogen is introduced for reduction carbonization, the mass ratio of methane and hydrogen mixture is 20:1, the gas flow rate is 0.45m / S, and the reduction carbonizat...

Embodiment 2

[0035] Dissolve ammonium metatungstate in water, prepare a 5wt% solution, and use ultrasonic vibration for 30 minutes under a stable room; while stirring with a magnetic stirrer, introduce the solution into a spray dryer for spray drying to obtain hollow spherical H 2 WO3 Precursor of microsphere particles; put the dried precursor into a quartz boat and place it in a tubular resistance furnace, pass hydrogen gas at 400°C for 2 hours of roasting heat treatment, then raise the temperature to 900°C, and pass in methane , Hydrogen mixed gas for reductive carbonization, the mass ratio of methane and hydrogen mixed is 20:1, the gas flow rate is 0.45m / S, and the reductive carbonization time is 12 hours. After the reaction, the product was cooled to room temperature with the furnace to obtain a tungsten carbide powder sample. The prepared tungsten carbide carrier was analyzed by scanning electron microscope. It can be seen from Fig. 4 that the obtained tungsten carbide carrier is holl...

Embodiment 3

[0037] The tungsten carbide-supported platinum catalyst prepared in Example 1 was prepared into a powder microelectrode, and the hydrogen evolution catalytic activity of the tungsten carbide-supported platinum powder microelectrode was tested by cyclic voltammetry. The results are shown in the curve in Figure 5c. The instrument used is a microcomputer-controlled CHI660B electrochemical analyzer. The experiment uses a three-electrode test system, and the electrolyte is H 2 SO 4 (1mol / L), the reference electrode is a saturated calomel electrode, the counter electrode is a Pt sheet, the experimental temperature is 25°C, and the scanning speed is 0.1V / S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com