Total solution for water treatments

a technology of total solution and water treatment, which is applied in the direction of water/sewage multi-stage treatment, water/sewage treatment by oxidation, electrolysis components, etc. it can solve the problems of reducing the efficiency of ozone oxidation power consumption, jeopardizing the water quality of cdi treatment, and affecting the adhesion of active material deposited or plated film, etc., to achieve the effect of improving the efficiency of power consumption in ozone oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

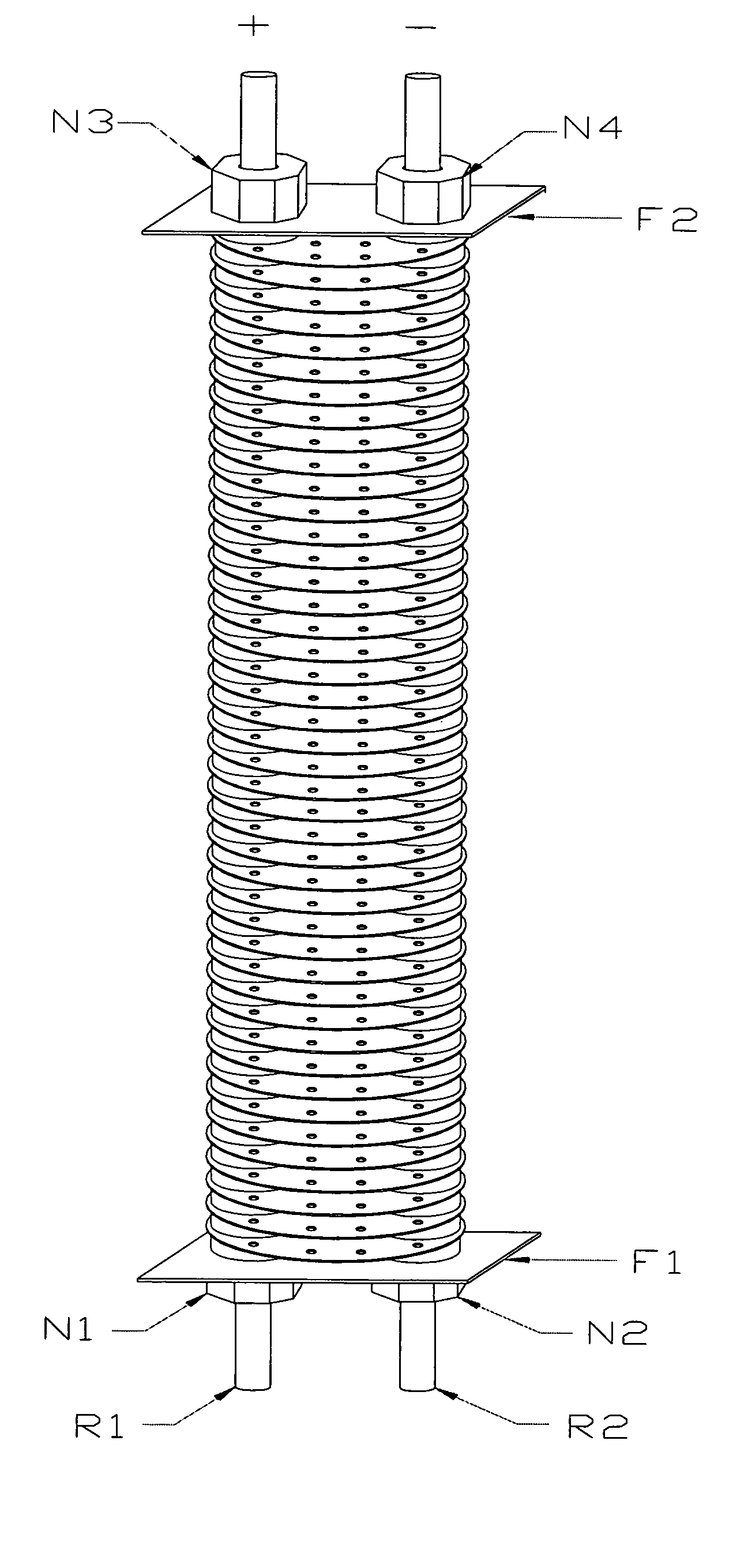

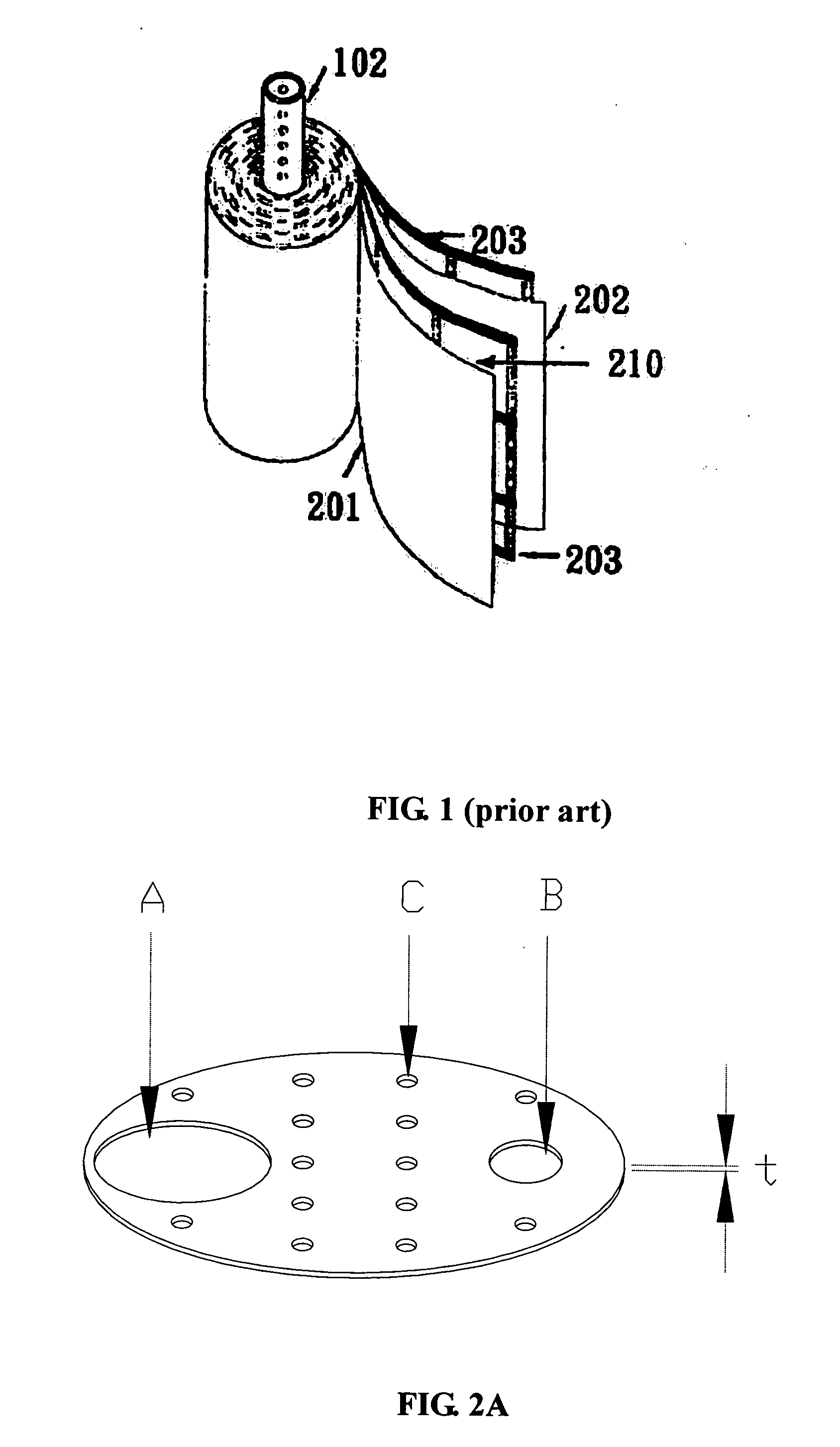

[0056]10 different reagent grade salts: CuSO4, FeSO4, Ca(NO3)2. Fe(NO3)2, Al(NO3)3, NaNO3, Zn(NO3)2, K3PO4, Na3PO4 and NaCl, are individually dissolved in 1 liter deionized water to form 10 pure solutions with TDS ranging from 700 to 1000 ppm. Each solution is deionized on 5 serially connected units of cylindrical FTC, as shown in FIG. 1, individually sealed in a plastic housing with a capacity of 600 ml. During test, each solution flows through the FTC pack continuously at 1 l / min. Each FTC has a geometric area of 1400 cm2 for each electrode to form the FTC roll, and 3V DC is applied across the two electrodes of FTC for ion removal. Since the 5 units of FTC are charged in parallel, every FTC will receive 3V of charging voltage. The total charging current is about 6A. FIG. 4 shows the reduction of TDS for each salt after 3 cycles wherein every cycle contains 3 minutes of charging for deionization and 2 minutes of discharging and rinsing for regeneration. Except the salts containing ...

example 2

[0057]1.5 liters of 1% ammonia (NH3) water is prepared for ozonation using an ozone reactor as revealed in U.S. Pat. No. 6,984,295, which is currently owned by the assignee of the present invention. A pair of platinum coated titanium meshes, each is 10 cm wide by 10 cm long with opening of 3.5 mm×6.5 mm, is used to form the ozone reactor. The ozone reactor is placed in the container of 1.5 liters ammonia water under the application of 8.5V average voltage and 1.75 A average current and PWM control. Only the TDS of the ammonia water during ozonation is measured, and the hourly variation of TDS is shown in FIG. 5A. About 6 hours since the ozonation is began, the TDS of solution levels off indicating that the decomposition of ammonia by ozone has been completed. Most ammonia may be decomposed by ozone according to the following equation:

[0058]Next, the ozonated water is deionized using a single FTC unit as example 1, as well as 3V DC for deionization. TDS of the water is reduced smooth...

example 3

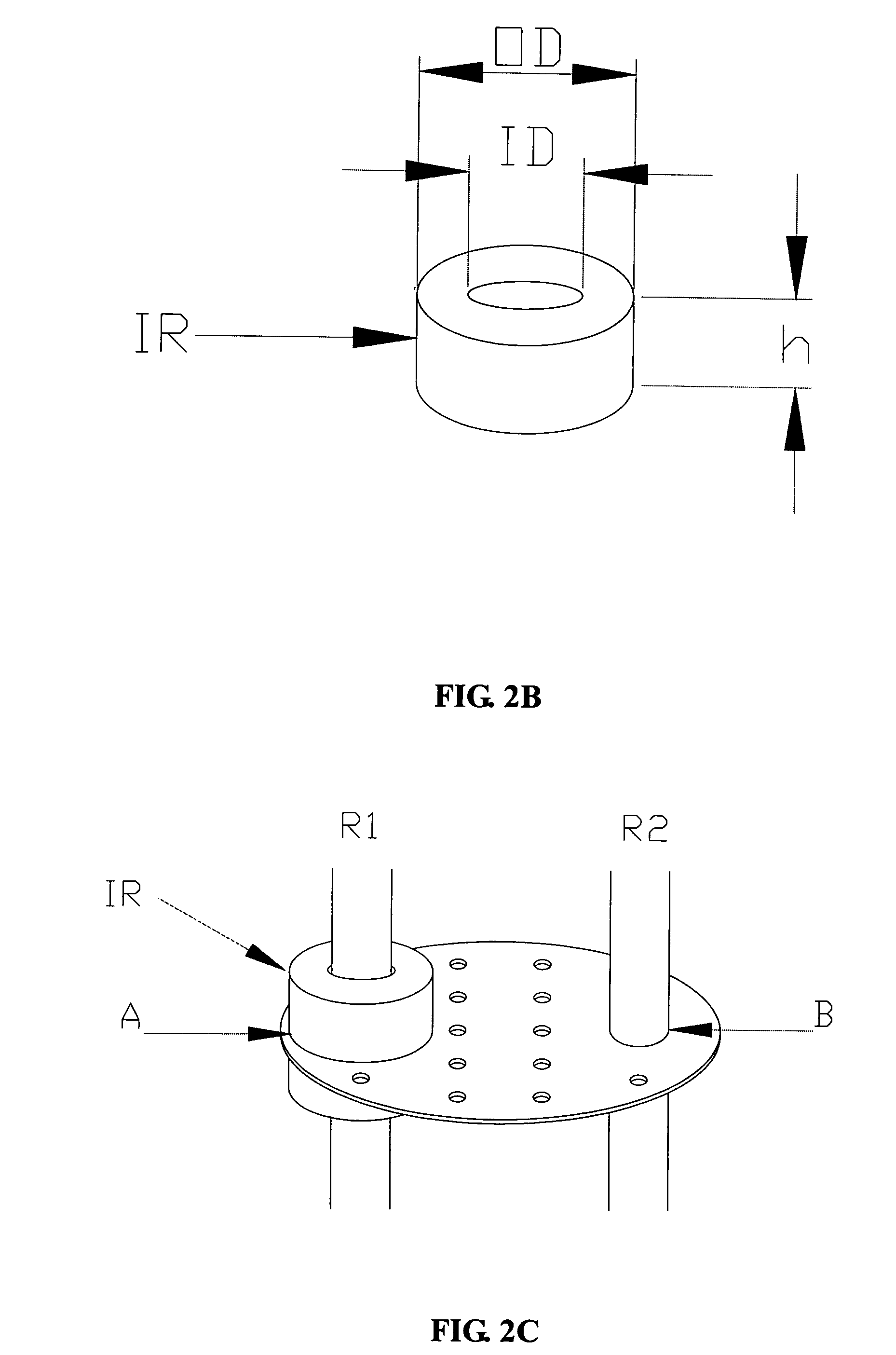

[0059]6 g of ammonia is dissolved in 2 liters tap water, which is mixed with 1 liter of filtered seawater (TDS=35,000 ppm). The salted ammonia water as prepared is first oxidized using an ozone reactor with electrode configuration of FIG. 2D concealed in a plastic housing as EXAMPLE 1. Iridium oxide (IrO2) is used as the ozone-forming material coated on titanium mesh, which has an opening of 1.5 mm×3.0 mm. A total of 32 pieces IrO2 / Ti disk electrodes of 5.3 cm diameter are disposed in the housing. The power for ozonation is set at 12V×10 A with the electrode polarities switched once every minute. The ammonia brine is circulated between the ozone reactor and a reservoir Table 1 lists the hourly variation of TDS, pH, voltage and current of ozonation

TABLE 1Ozonation of ammonia brine using an iridium oxide ozone reactorTime (hr)TDS (ppm)pHVoltage (V)Current (A)011,03010.43.810112,3009.903.910212,3009.703.910312,3009.203.910412,5007.904.010512,4008.174.010612,4008.184.010

[0060]If 2 liter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current voltage | aaaaa | aaaaa |

| current voltage | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com