Particulate Constructs For Release of Active Agents

a technology of active agents and constructs, applied in the field of compositions, can solve the problems of increasing the solubility of hydrophobic drugs, unable to meet the requirements of small particles, and ineffective approaches in small particles, and achieves the effect of reducing toxicity and high loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

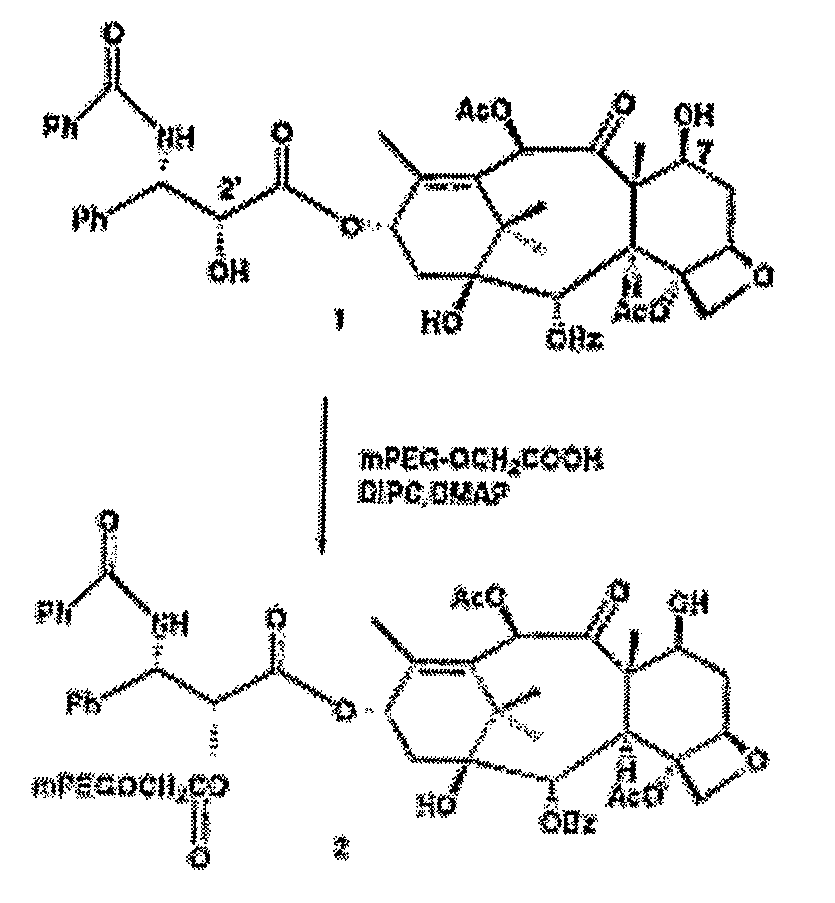

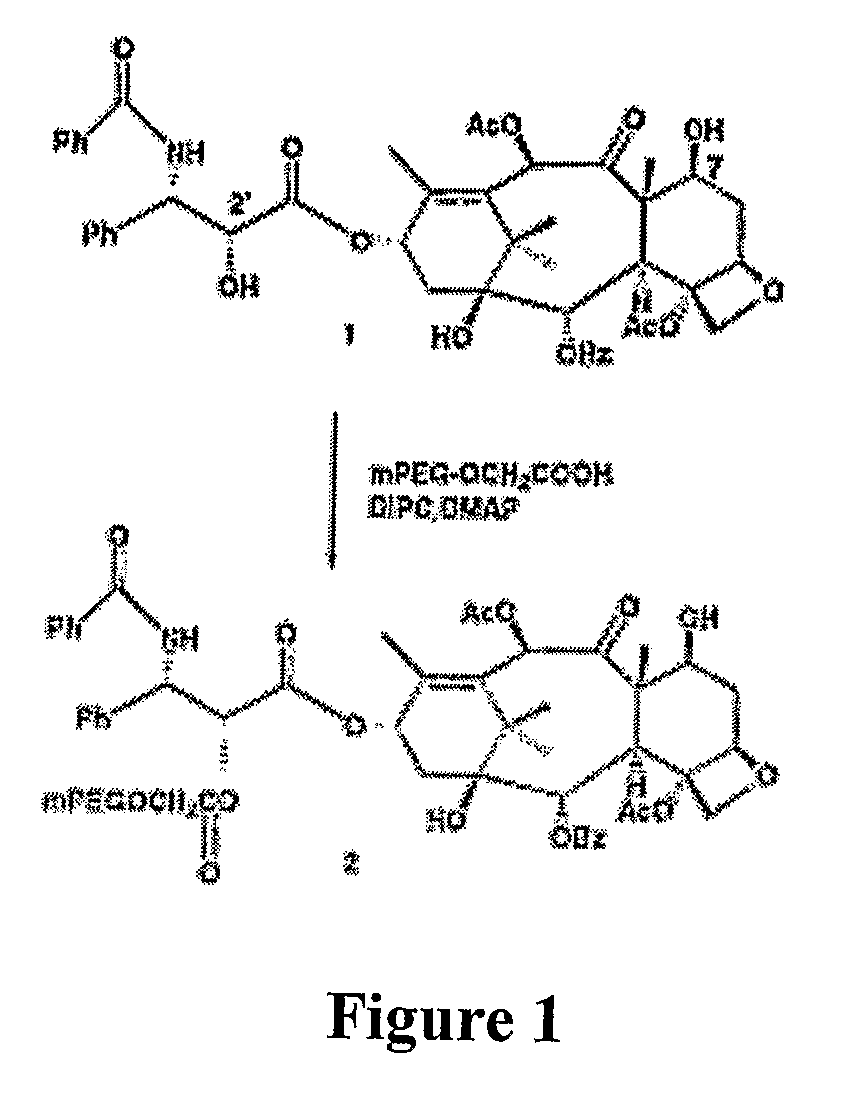

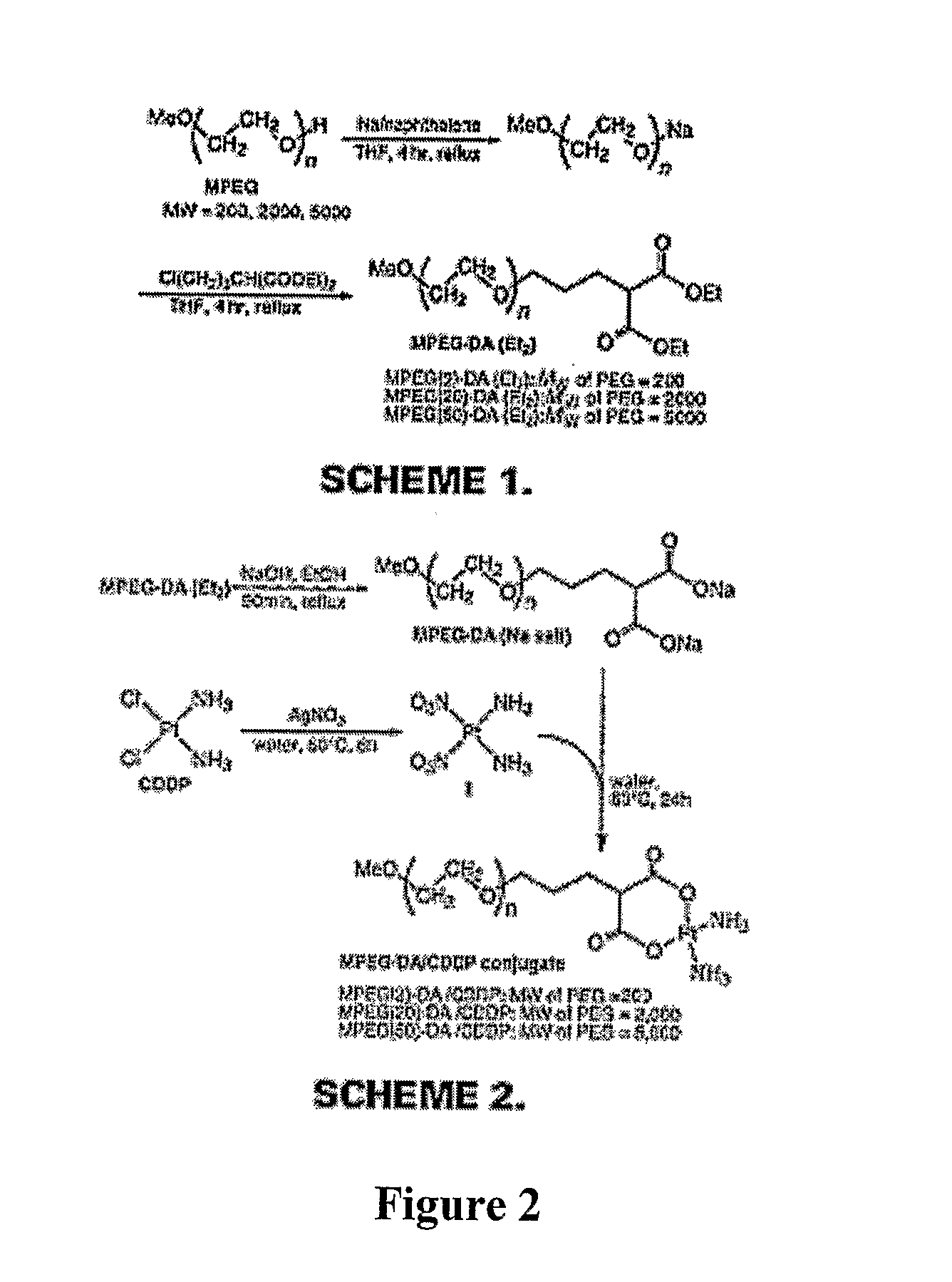

Method used

Image

Examples

example 1

Conjugation of Paclitaxel to Vitamin E Succinate (VitES)

[0137]280 mg of VitES were dissolved in 20 ml of dichloromethane and brought to 0° C. Then, 27 μL of diisopropylcarbodiimide were added, followed by 150 mg of paclitaxel and 33 mg of dimethylaminopyridine. The reaction vessel was warmed to room temperature, and left to react for 16 hours. The reaction solution was washed with 0.1 N hydrochloric acid, dried with magnesium sulfate, filtered, and dried in vacuo. The product was characterized and verified to be paclitaxel-VitES by High Performance Liquid Chromatography (HPLC) and Nuclear Magnetic Resonance (NMR) analysis.

example 2

Conjugation of Paclitaxel to Polycaprolactone with Terminal Carboxylic Acids

[0138]A. 79 mg of PCL (MW 2.2 kg / mole, PCL2.2) end-terminated with carboxylic acid groups were dissolved in 20 ml of dichloromethane and brought to 0° C. 26 μL of diisopropylcarbodiimide were added, followed by 146 mg of paclitaxel and 32 mg of dimethylaminopyridine. The reaction vessel was warmed to room temperature, left to react for 16 hours, and washed with 0.1 N hydrochloric acid, dried with magnesium sulfate, filtered, and dried in vacuo. The amount of excess paclitaxel in the reaction product was reduced by recrystallization from amyl acetate. The product was characterized and verified as PCL-paclitaxel by HPLC and NMR analysis.

[0139]B. The procedure of paragraph A was also carried out using PCL1.45 and PCL3.5.

example 3

Nanoparticles with Methoxy Polyethylene Glycol-Polycaprolactone (mPEG-PCL) and Paclitaxel-VitE

[0140]As a control, 15 mg of methoxy polyethylene glycol-(MW 5 kg / mole)-polycaprolactone (methoxy polyethylene glycol molecular weight of 5 kg / mole, PCL molecular weight of 7 kg / mole) (mPEG5-PCL7) in THF to make a 1 wt % solution (w:w) of mPEG5-PCL7. Then, 8 mg of paclitaxel and 10 mg of VitES were added to the solution and mixed using the vortex mixer at a flow rate of 12 ml / min against water at 120 ml / min. Crystals were visible about 20 minutes after mixing, and no particles were detected by Dynamic Light Scattering (DLS).

[0141]20 mg of mPEG5-PCL7 were dissolved in THF to make a 0.5 wt % solution. Then, 23 mg of paclitaxel-VitES along with 17.4 mg VitES prepared as described in Example 1 was added to make a 0.58 wt % paclitaxel-VitES solution, and mixed using the vortex mixer at a flow rate of 12 ml / min against water at 120 ml / min. Nanoparticles with an average diameter of 126 nm, as dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com