Bitumen extraction and asphaltene removal from heavy crude using high shear

a technology of asphaltene removal and heavy crude, which is applied in the field of enhanced/or bitumen, can solve the problems of difficult transportation and upgrading, difficult to recover, and expensive to process into gasoline, diesel fuel, and other products, and achieve high shear and improve the recovery and processing of heavy crude bitumen. , the effect of high shear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

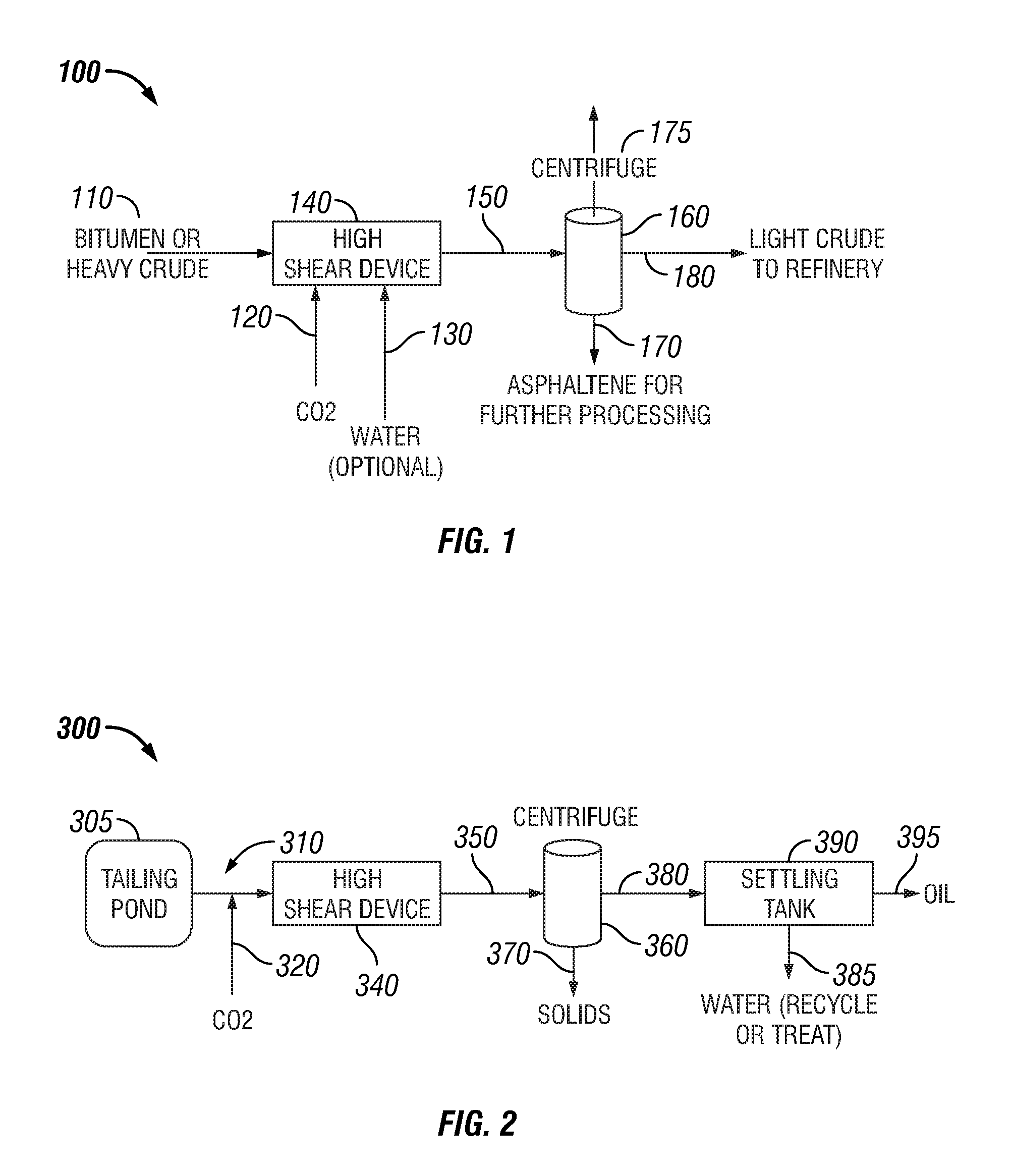

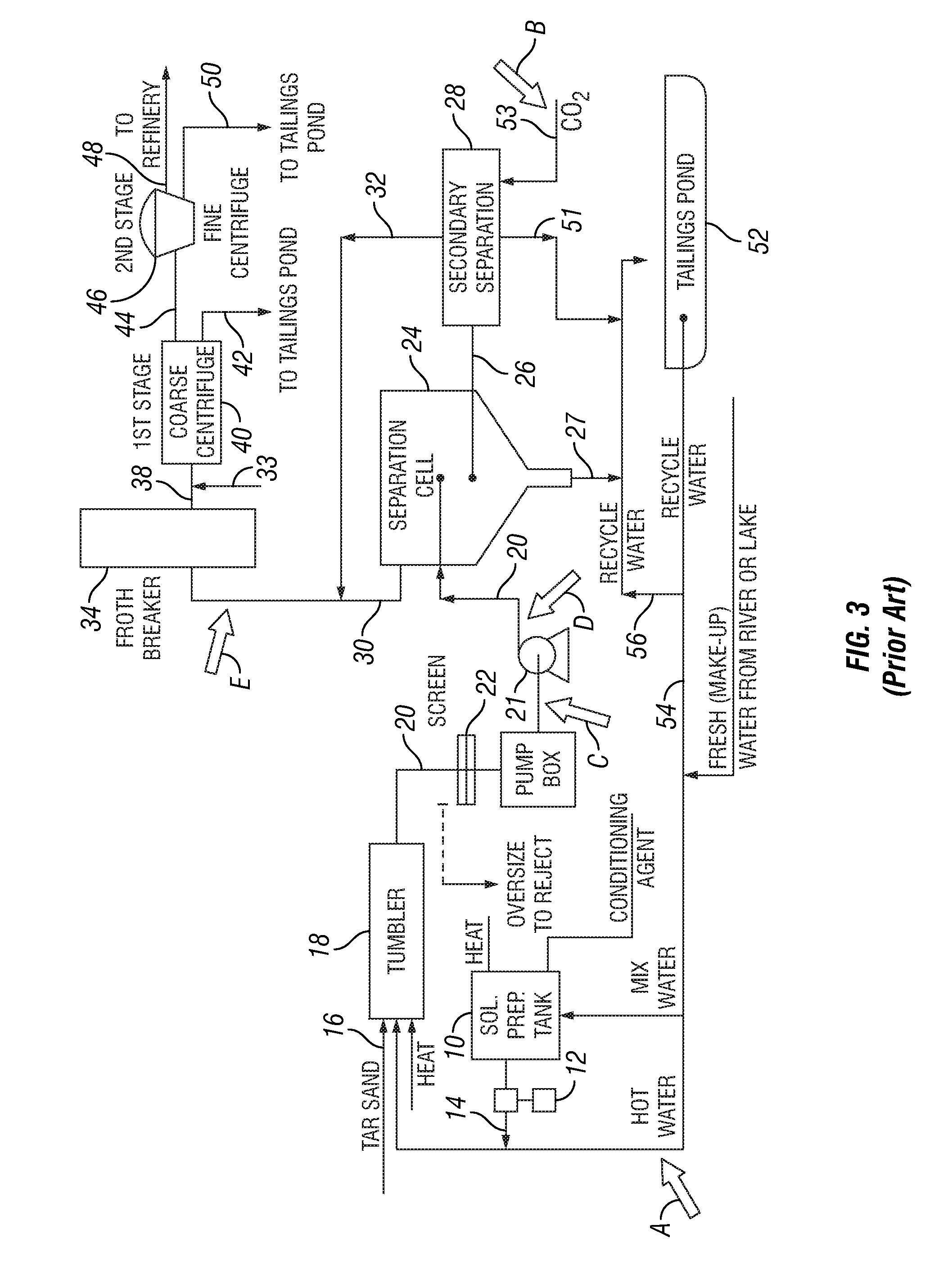

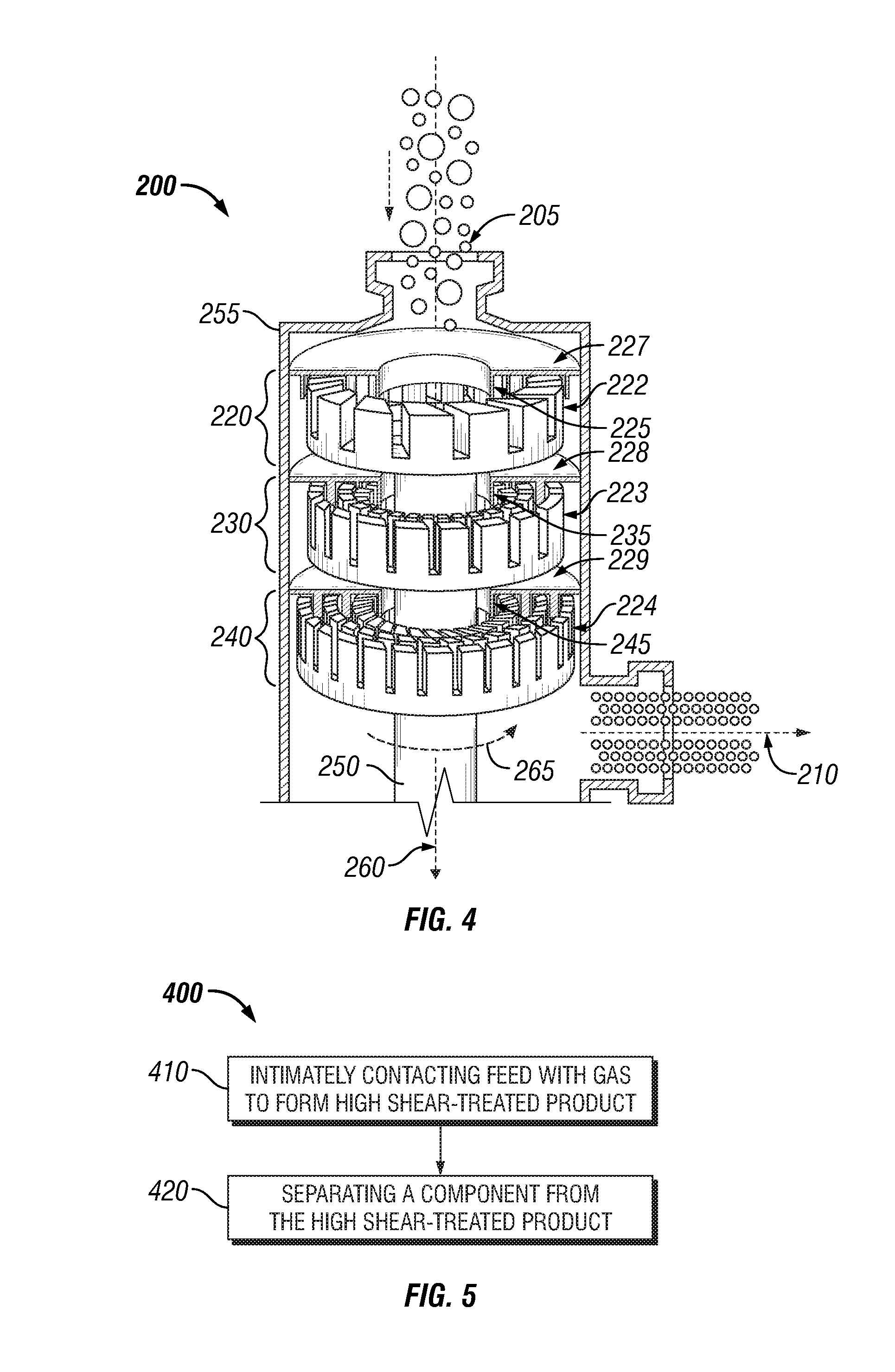

[0041]Overview. Herein disclosed are systems and methods of removing a component from a stream produced during recovery and / or processing of heavy crude oil or bitumen (e.g. from tar sands). The system and method are utilized, in embodiments, to precipitate asphaltenes from bitumen or heavy crude oil. In embodiments, the system and method are suitable for facilitating recovery of water from slurries (comprising sediments / sand particles) that are conventionally introduced into tailings ponds or recycled back to the process. The system comprises an external high shear mechanical device to provide rapid contact and mixing of reactants in a controlled environment in the reactor / mixer device. In embodiments, the system and method allow removal of asphaltenes at lower temperatures and / or pressures than conventional methods or more rapid and complete removal of asphaltenes. In embodiments, the system and method allow extraction of bitumen from tar sands with utilization of less water by fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| bubble diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com