Fluorescent particle, with semiconductor nanoparticles dispersed therein, fabricated by the sol-gel process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Silica Glass Fine Particles

[0116]CdSe / ZnS nanoparticles (CdSe core, ZnS shell) whose surface is coated with dodecylamine were prepared by a known method (Nano Letters, Vol. 1, p. 207 (2001) and Colloids and Surfaces A, Vol. 202, p. 145 (2002)). The nanoparticles were dispersed at a concentration of 20 μM in a toluene solution. The PL efficiency was measured to be 35%. The emission wavelength was about 620 nm, and the half-bandwidth (full width at half-maximum) of the emission spectrum was about 33 nm.

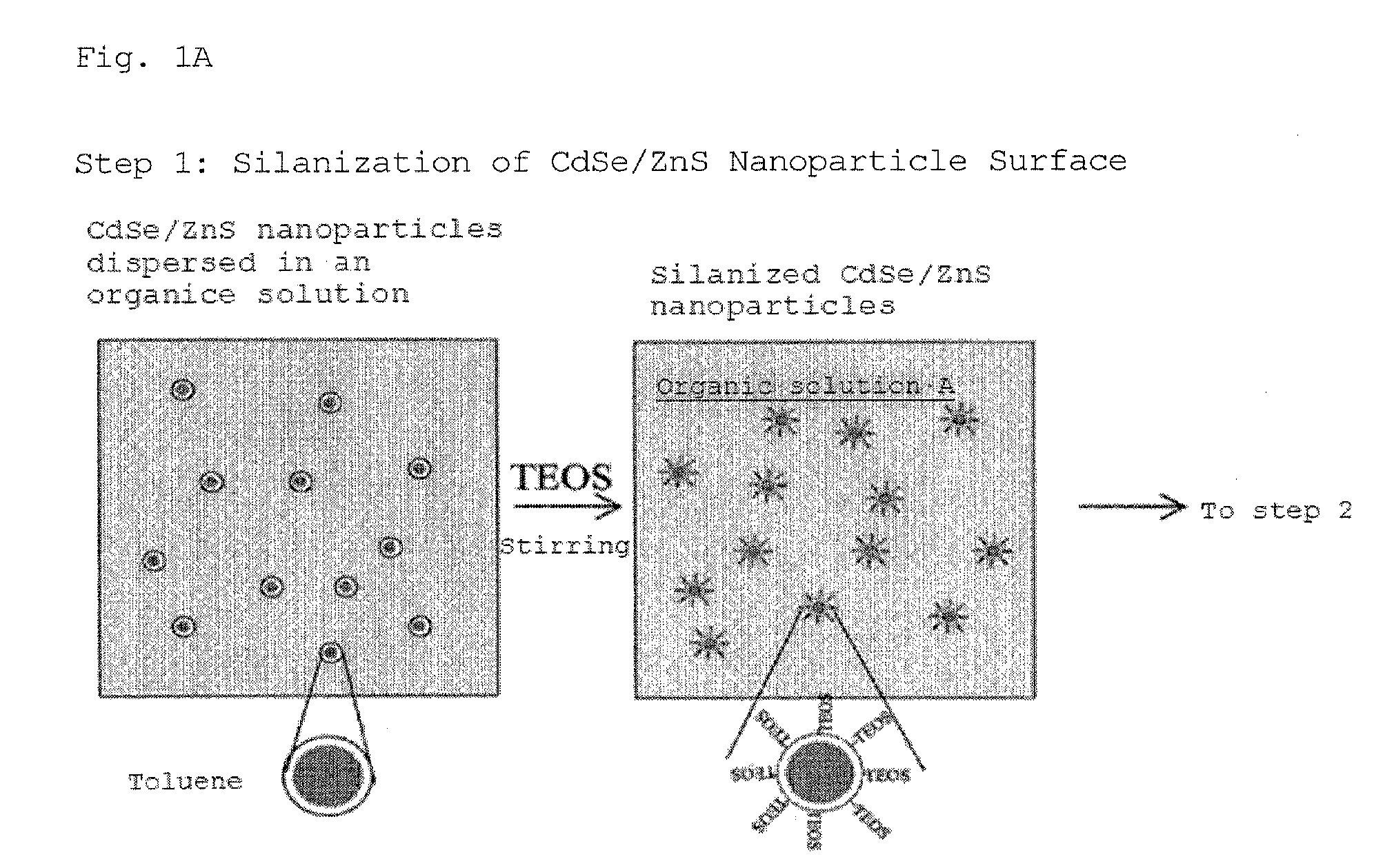

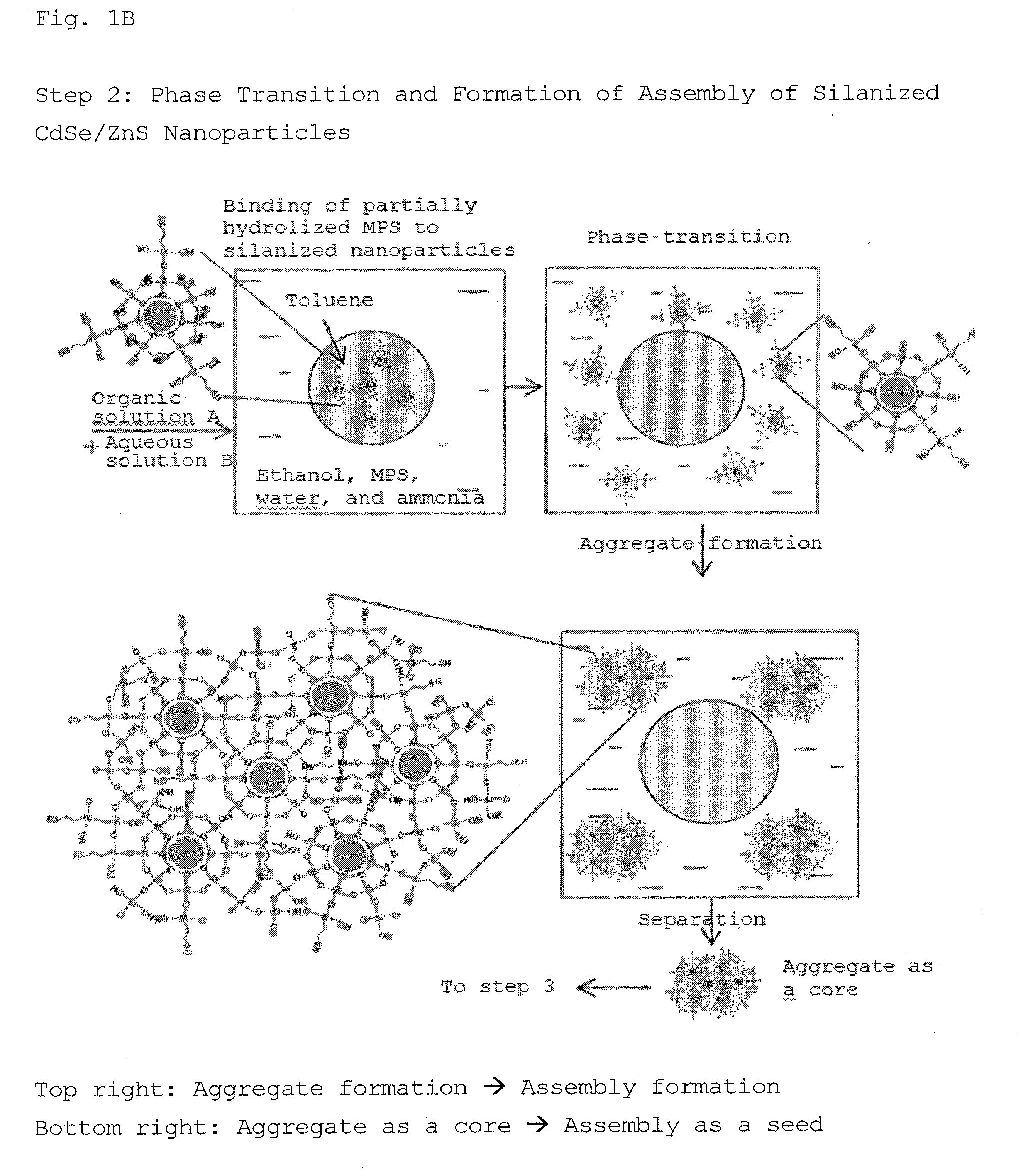

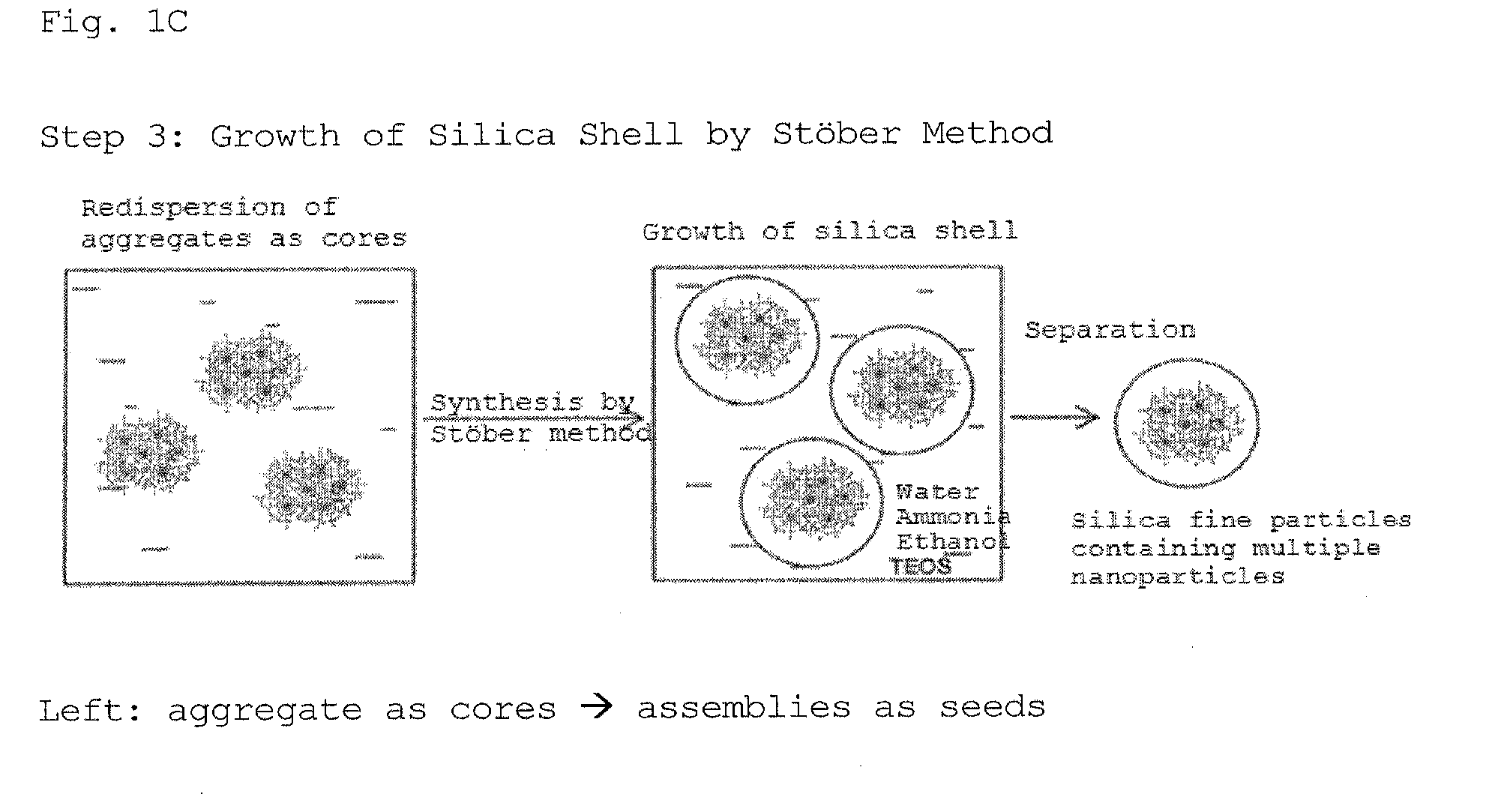

[0117]Next, silica glass fine particles in which fluorescent nanoparticles are dispersed were prepared via 3 stages from step 1 to 3 shown in FIGS. 1A to 1C. Unless otherwise stated, the synthesis was carried out at room temperature in the atmosphere.

[0118]In step 1, tetraethoxysilane (TEOS, 10 μL) was added to a toluene solution in which nanoparticles are dispersed (0.4 mL, 1.5 μmol / L), and the mixture was stirred for 3 hours, thereby obtaining organic solution A. In regar...

example 2

[0133]Hydroxyl groups are present on the surface of the silica glass fine particles prepared in Example 1. In order to apply the silica glass fine particles as fluorescent probes in the field of biotechnology, the surface of the silica glass fine particles were modified with various functional groups; and further, antibodies were conjugated thereto.

[0134]When MPS was used after the formation of a silica glass layer in Example 1, fine particles coated with thiol groups were prepared.

[0135]The fine particles after the formation of the silica glass layer were dispersed in pure water, and 0.5 mL of fine particles (nanoparticle concentration of 1 μM) was extracted and added to a mixture of MPS (2 μL) and ethanol (30 μL). After stirring, precipitate was obtained by centrifugation, washed with pure water, and dispersed in a PBS (concentration: 10 μM) solution to obtain an amount of 0.5 mL. 0.1 mL was extracted therefrom, and a PBS buffer solution (10 μL) in which the concentration of strep...

example 3

[0148]When the amount of MPS used in “Synthesis of Silica Glass Fine Particles” in Example 1 was decreased to 0.5 μL, the size of nanoparticle assemblies formed was increased. The surface of these assemblies was coated with silica glass in the same manner as in Example 1, thereby obtaining fluorescent fine particles. At this time, the PL efficiency when the semiconductor nanoparticles were dispersed at a concentration of 10 nmol / L in a HEPES solution was about 25%. It was found by electron microscope observation that the fluorescent fine particles have an average particle size of 95 nm. Further, it was confirmed that at least 160 nanoparticles are dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com