Fiberglass mesh scrim reinforced cementitious board system

a technology of cementitious boards and fiberglass mesh, which is applied in the field of cementitious panels or boards, can solve the problems of fiberglass, lack of chemical attack resistance of cement ingredients, and substantial unaffected water, and achieve the effects of improving the long-term durability of the resulting mesh, improving runnability and field performance, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

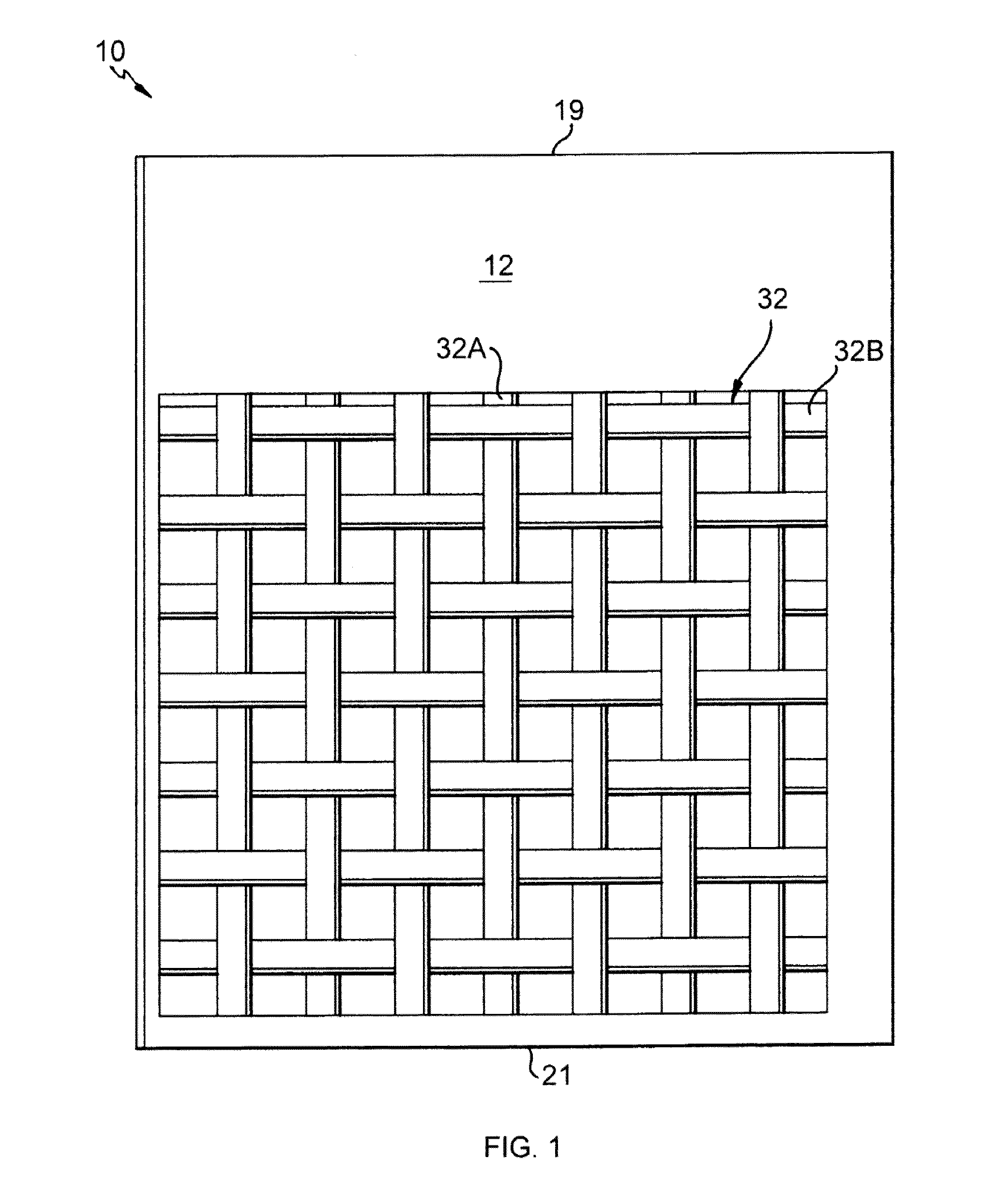

[0137]Specific examples of typical cement boards made with a fiberglass mesh scrim made with a conventional G-75 fiberglass yarn available from the St-Gobain Technical Fabrics, which has a yarn fiber density of about 7500 linear yards per one pound of yarn and has a typical mesh grid structure with 8 to 7.5 strands per inch in the longitudinal (machine) and transverse (cross machine) directions compare to an improved fiberglass mesh scrim which is made from a G-37 fiberglass yarn which has also been made by St-Gobain technical Fabrics, which is made from a similarly water and alkali resistant coated fiberglass fabric and mesh constructed but which is thicker in diameter and which has a density of about 3700 linear yards per one pound of fiberglass yarn and which is made into a mesh with 4 to 5 strands per inch e.g. 4.5×4.5 strands per inch, in the longitudinal (machine) and transverse (cross machine) directions, as shown in Table 5, below.

TABLE 5As-is and Long Term Flexural Strength...

example 3

[0144]A number of lab test panels were made from the formulations of TABLE 10 and TABLE 11 (see Example 4) in a mold with the bottom scrim laid in first, followed by pouring the cementitious slurry and then removing excess slurry with a trowel to give a thickness of 0.5″. The top scrim is then placed over the top of the slurry and then the surface is gently finished with a trowel to make sure the top scrim is embedded into the slurry. The samples are sealed and cured at 90° F. / 90% RH for 7 days before the flexural strength and nail pull testing is performed. The slurry formulation used for the lab cast is the same formulation in manufacturing cement panels is used at the plants to evaluate the effect of the use of a wide range of panel density on the nail pull strength obtained with the 4×4 fiberglass mesh scrim of the invention.

[0145]The manufactured cement boards were skin-reinforced using alkali-resistant, polyvinyl chloride (PVC) coated fiberglass mesh embedded in cementitious s...

example 4

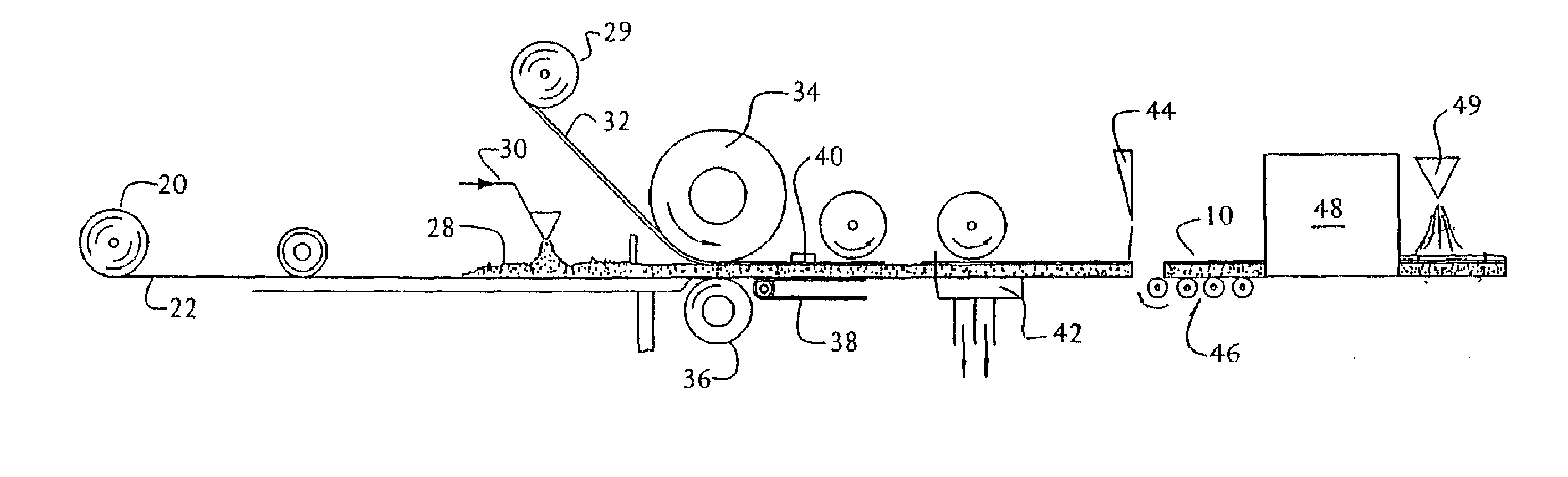

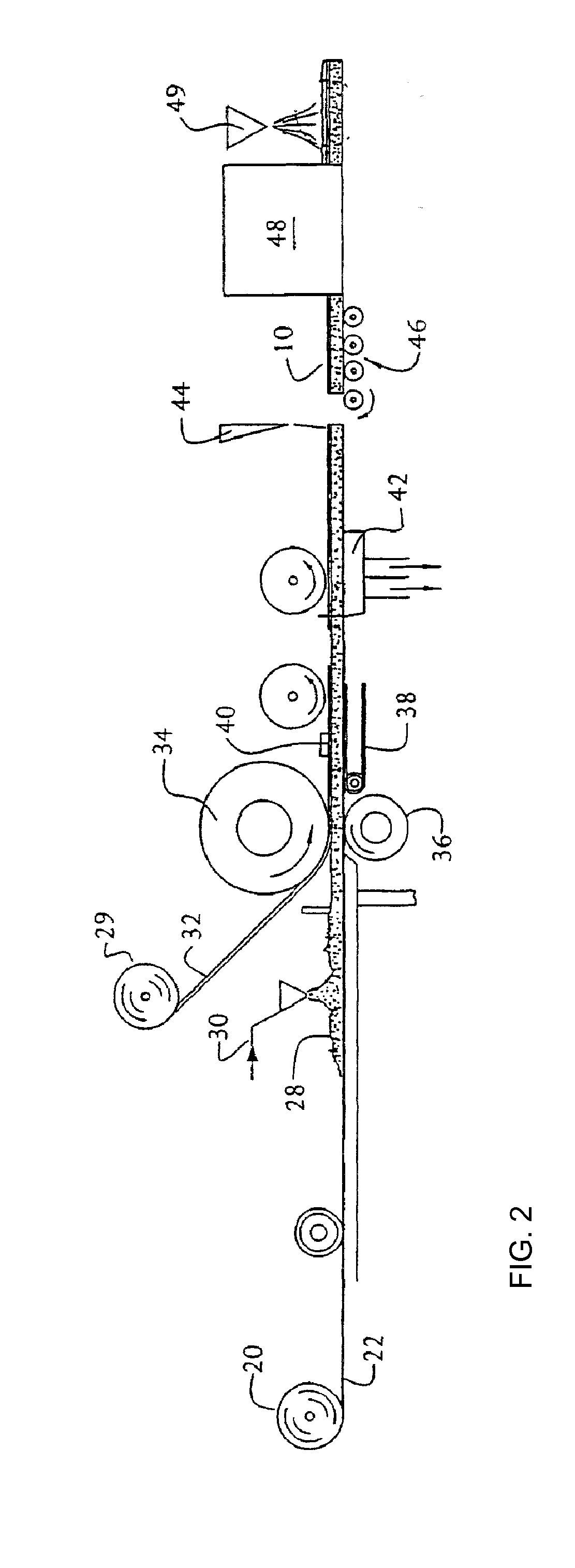

Plant Scale Production of Cement Board Made with 4×4 Fiberglass Mesh Scrim of the Present Invention Compared to Cement Board Made with Conventional 8×8 Fiberglass Mesh Scrim

[0156]Since use of more open mesh like the G-37 mesh scrim for the tighter mesh of the conventional G-75 mesh scrim could present a potential problem for nail pull performance, this property was tested on the following plant trial samples of cement board in this Example.

[0157]The following examples illustrates producing lightweight cement boards in a commercial manufacturing process using the improved fiberglass mesh scrim of the invention. The raw materials used included a cementitious reactive powder of Portland cement Type III, class C fly ash, and calcium sulfate dihydrate (landplaster), chemically coated perlite, expanded clay and shale aggregate and added liquids. The liquids, e.g., triethanolamine, were admixtures added as aqueous solutions. In addition, sodium citrate and sulfonated napthalene superplasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com