Glucosamine and method of making glucosamine from microbial biomass

a technology of microbial biomass and glucosamine, which is applied in the direction of application, biocide, sugar derivates, etc., can solve the problems of not necessarily providing any allergic risk, glucosamine exposure to shellfish, and significant variation in composition of wild shellfish, etc., to achieve low ash content, low impurity level, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0046]The invention will be further explained by the following non-limiting illustrative examples. Unless otherwise indicated, all amounts are expressed in parts by weight.[0047]Example 1

[0048]Citric biomass was pretreated with a 4 percent aqueous sodium hydroxide (NaOH) solution in an autoclave at 120° C. for 1 hour. This step removed excess proteins and other undesirable materials. The biomass was then thoroughly washed with de-ionized water until its pH was approximately 7.0. This washed material was mixed with concentrated hydrochloric acid (HCl) and water to form a mixture of 10 to 15 percent HCl and 5 to 6 percent biomass, based upon dry weight of the biomass. This mixture was heated at reflux. Samples were taken from time to time, and the reaction analyzed with a high-pressure liquid chromatograph available from Dionex HPLC under the trade designation “DX-500”.

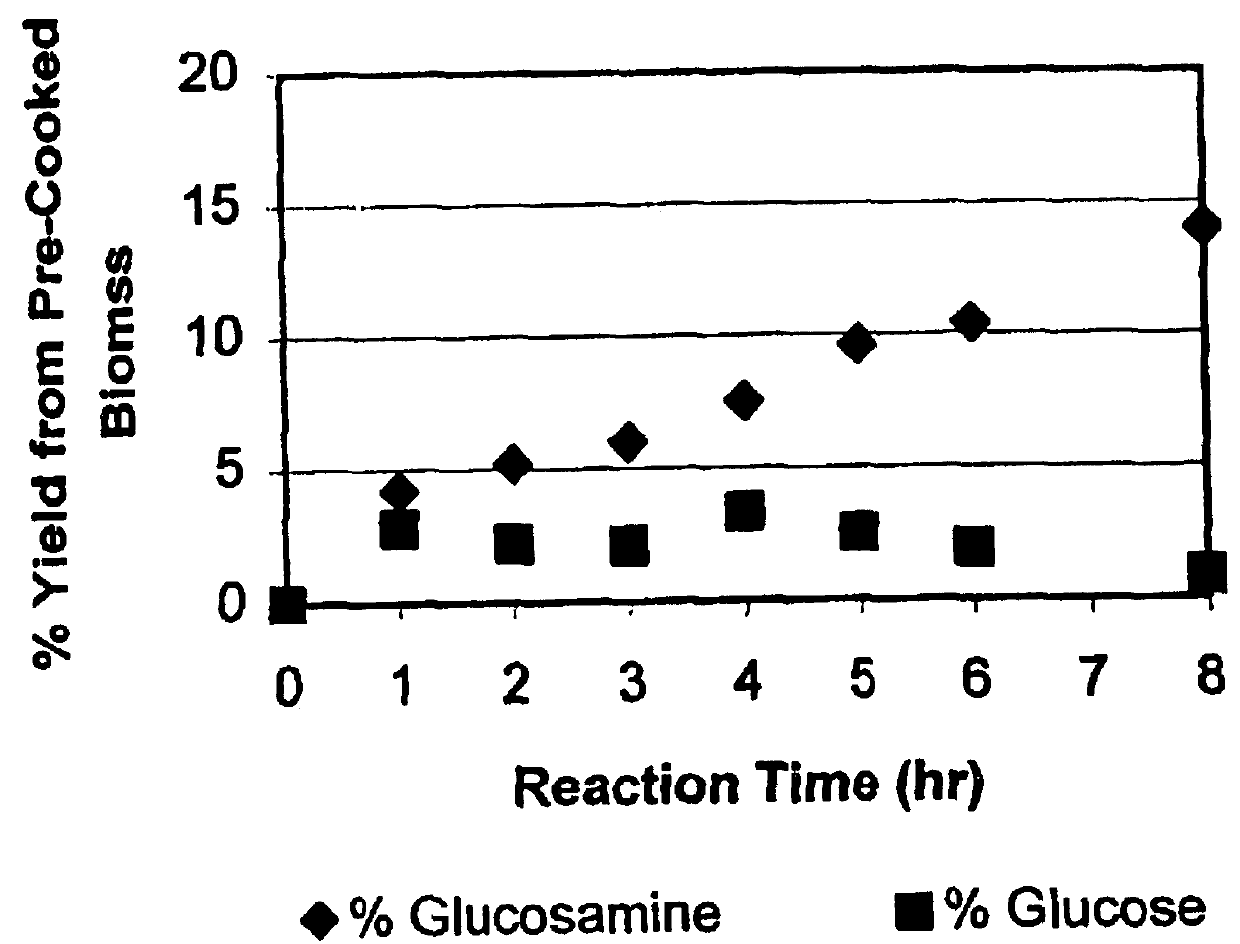

[0049]The results are provided in FIG. 1, which shows a chart indicating glucosamine production, and shows that the g...

example 2

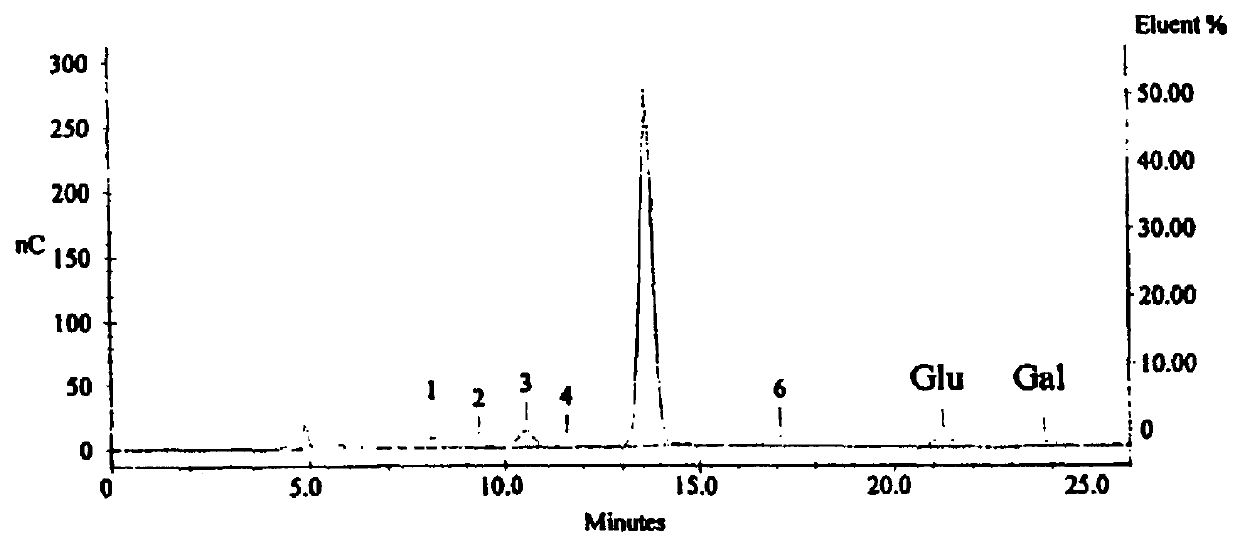

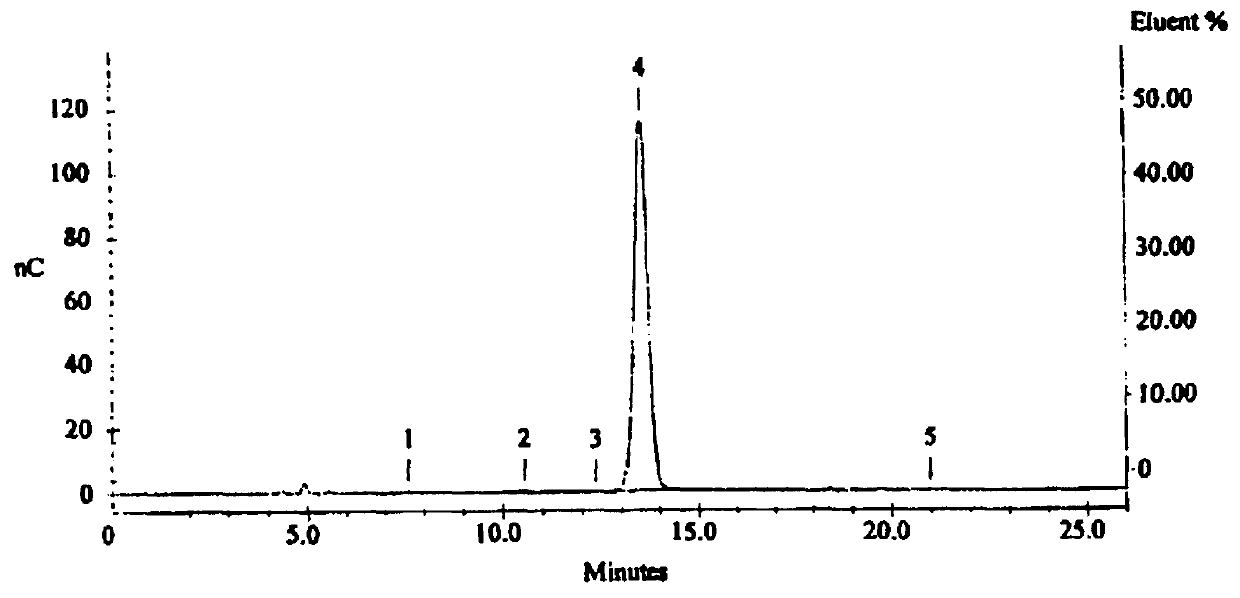

[0050]Following reaction, the mixture was filtered, and the filtrate evaporated using a rotating evaporator manufactured by RotaVap to increase the glucosamine concentration of the solution. The final volume was reduced to about 10 to 20 ml. To this solution was added 20 ml of ethanol and the solution swirled to promote precipitation of glucosamine and enhance yield. These glucosamine precipitates were obtained by filtration and were further washed with alcohol until the color became white. FIG. 3 shows a chromatogram of the product, indicating greater than 97 percent glucosamine.[0051]Example 2

[0052]Example 1 was repeated, but the pretreated biomass was maintained under reflux conditions for 13 hours. The resulting glucosamine was greater than 98 percent pure.

example 3

[0053]The foregoing detailed description and examples have been given for clarity of understanding only. No unnecessary limitations are to be understood from this description or examples. The invention is not limited to the exact details shown and described, for variations will be included within the invention defined by the claims.[0054]Example 3

[0055]The Gram-positive bacteria Streptomyces griseus and Bacillus subtilis were isolated as individual colonies on trypticase-soya agar for growth in pure culture. Each was separately inoculated into 1 L of sterile trypticase-soya broth and grown for 48 hours at 32° C. and 170 rpm. The mature cultures were harvested by centrifugation for 10 minutes at 7,500 g and 4° C. Each pellet was washed in 50 mL of phosphate buffer and centrifuged as above. The pellets of bacterial biomass were stored at −20° C. until processing.

[0056]Additionally, three cultures of unknown gram positive bacteria were isolated as single colonies on Tripticase Soy Agar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree specific rotation | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| reaction temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com