Patents

Literature

36results about How to "Interference with control signal transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and process method thereof

ActiveCN103400775AHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesWire widthEpoxy

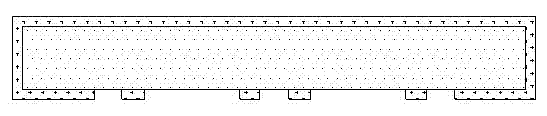

The invention relates to a packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and a process method thereof. The packaging structure comprises a pad (1) and pins (2), wherein conductive columns (3) are arranged on the front surfaces of the pins (2); a first chip (4) is normally bonded on the front surface of the pad (1); first molding compounds or epoxy resins (9) are encapsulated in the peripheral areas of the conductive columns (3), the first chip (4) and a first metal wire (5); second chips (7) are flipped on the back surfaces of the pad (1) and the pins (2); second molding compounds or epoxy resins (10) are encapsulated in the back areas of the pad (1) and the pins (2) and the peripheral areas of the second chips (7); and first metal balls (17) are arranged on the conductive columns (3). By virtue of the packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and the process method thereof, the problems of limitation of the whole packaging functional integrity caused by difficulty in embedding of an object into a conventional metal lead frame or a conventional organic substrate and requirements on smaller wire width and smaller wire interval of the conventional organic substrate can be solved.

Owner:江苏尊阳电子科技有限公司

Firstly-packaged secondly-etched three-dimensional system level chip front-installed bump packaged structure and technology method thereof

ActiveCN103515249AHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyLead frame

The invention relates to a firstly-packaged secondly-etched three-dimensional system level chip front-installed bump packaged structure and a technology method of the firstly-packaged secondly-etched three-dimensional system level chip front-installed bump packaged structure. The packaged structure comprises a base island (1) and pins (2). Electric conduction pillars (3) are arranged on the front faces of the pins (2), a first chip (4) is front installed on the front face of the base island (1), the peripheral areas of the electric conduction pillars (3), the first chip (4) and a first metal wire (5) are all packaged with first molding compounds or epoxy resin (9), and a second chip (7) is front installed on the back face of the base island (1). The back areas of the base island (1) and the pins (2) and the peripheral areas of the second chip (7) and a metal wire (8) are all packaged with second molding compounds or epoxy resin (10). First metallic balls (17) are arranged on the electric conduction pillars (3). The packaged structure has the advantages that the problems that due to the fact that a traditional metallic lead frame or a traditional organic substrate can not be buried into an object, the integration level of the whole packaging function is limited, and the traditional organic substrate needs a smaller line width and a narrower distance between lines are solved.

Owner:江阴芯智联电子科技有限公司

Secondary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation bump structure and process method

ActiveCN103646939AAchieve privacyChieve protectiveSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingOxidation resistant

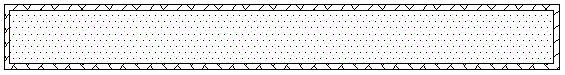

The invention relates to a secondary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation bump structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The back surface of each base island (2) is flush with the step surface of each pin (3). The step surface of each pin (3) is provided with a metal layer (4). The back surface of each base island (2) is normally equipped with a chip (6). The surface of the chip (6) is connected with the surface of the metal layer (4) through a metal line (7). The metal substrate fame (1) is internally filled with plastic packaging material (8). The front surface of the plastic packaging material (8) is flush with the step surface of the pin (3). The back surface of the plastic packaging material (8) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (9). The back surface of each pin (3) is provided with a metal ball (10). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame is solved.

Owner:JCET GROUP CO LTD

One-time eroding-before-plating metal frame subtraction embedded chip inversely-arranged salient point structure and technological method

ActiveCN103681580AAchieve privacyChieve protectiveSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a one-time eroding-before-plating metal frame subtraction embedded chip inversely-arranged salient point structure and a technological method. The one-time eroding-before-plating metal frame subtraction embedded chip inverse arranged salient structure is characterized in that a metal substrate frame is included, a paddle and pins are arranged in the metal substrate frame, chips are arranged on the back face of the paddle and the step surfaces of the pins through bottom filled glue, plastic packaging materials wrap the area of the periphery of the paddle, the area between the paddle and the pins, the area between the pins, the areas on the upper portion of the paddle, the areas on the upper portions of the pins, the area on the lower portion of the paddle, and the area on the lower portions of the pins and the chips, the plastic packaging materials are aligned with the upper surface and the lower surface of the metal substrate frame, anti oxidation layers are plated on or organic solderability preservative (OSP) wraps the front face of the paddle, the front faces and the back faces of the pins and the surface of the metal substrate frame, and metal balls are arranged on the back faces of the pins. The one-time eroding-before-plating metal frame subtraction embedded chip inversely-arranged salient point structure has the advantages of being capable of solving the problem that the function and the application performance of a metal wire frame are restricted due to the fact that objects cannot be buried in the plate thickness of the traditional metal wire frame.

Owner:JCET GROUP CO LTD

Packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and process method thereof

ActiveCN103400769AHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

The invention relates to a packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and a process method thereof. The structure comprises a pad and pins, wherein a first chip is arranged on the front surface of the pad; second chips are flipped on the back surfaces of the pad and the pins through bottom filling adhesives; the front surfaces of the first chip and the pins are connected through metal wires; conductive columns are arranged on the front surfaces of the pins; molding compounds are encapsulated in the peripheral area of the pad, the areas between the pad and the pins and between each two pins, the upper areas of the pad and the pins, the lower areas of the pad and the pins, and the external areas of the first chip, the second chips, the metal wires and the conductive columns; anti-oxidation layers are plated on the surfaces, exposed from the molding compounds, of the pins and the conductive columns; and metal balls are arranged on the tops of the conductive columns. By virtue of the packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and the process method thereof, the problem of limitation of the whole packaging functional integrity caused by difficulty in embedding of an object into a conventional metal lead frame or a conventional organic substrate can be solved.

Owner:江苏尊阳电子科技有限公司

One-time etched-before-plated metal frame subtraction embedded chip inverted flat pin structure and technological method thereof

ActiveCN103681581AInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesThick plateAdhesive

The invention relates to a flip chip one-time etching combined type flat pin metal frame structure and a technological method thereof. The metal frame structure is characterized in that a metal base plate frame is included, base islands and pins are arranged inside the metal base plate frame, and chips are arranged on the back faces of the base islands and the step surfaces of the pins through underfill adhesives; the areas on the peripheries of the base islands, the areas between the base islands and the pins, the areas between the pins, the areas on the upper portions of the base islands and the pins, the areas on the lower portions of the base islands and the pins, and the outsides of the chips are all coated with molding compounds in a sealing mode; the molding compounds are flush with the upper surface and the lower surface of the metal base plate frame; anti oxidation layers are plated on or organic solderability preservative (OSP) wraps the front faces of the base islands, the front faces and the back faces of the pins and the surface of the metal base plate frame. The metal frame structure and the technological method thereof have the advantage of being capable of solving the problem that an object can not be embedded into a thick plate in a traditional metal lead frame, so that the functionality and application performance of the metal lead frame are limited.

Owner:JCET GROUP CO LTD

Packaging-first-etching-second chip upside-upward-installation three-dimensional system-in-package structure and process method

ActiveCN103413767AHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyLine width

The invention relates to a packaging-first-etching-second chip upside-upward-installation three-dimensional system-in-package structure and a process method. The structure comprises a paddle (1) and a lead (2). The front of the lead (2) is provided with a conductive post (3), the front of the paddle (1) is provided with a first chip (4) in an upside-upward mode, the periphery of the conductive post (3), the periphery of the first chip (4) and the periphery of a first metal wire (5) are respectively coated with first molding compound or epoxy resin (9), the surface, exposed out of the first compound or the epoxy resin (9), of the conductive post (3) is provided with an anti-oxidation layer (11), the back of the paddle (1) is provided with a second chip (7) in an upside-upward mode, and the back of the paddle (1), the back of the lead (2), the area on the periphery of the second chip (7) and the area on the periphery of a second metal wire (8) are coated with second molding compound or epoxy resin (10). The structure has the advantage of being capable of solving the problems that an article cannot be embedded in a traditional metal lead frame or an organic substrate and accordingly the integration degree of the whole packaging function is limited, and the traditional organic substrate needs a smaller line width and a smaller distance between wires.

Owner:江阴芯智联电子科技有限公司

One-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure and technological method

ActiveCN103681583AInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingLead frame

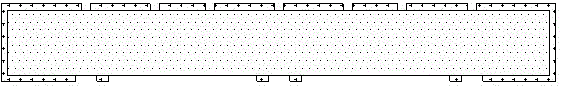

The invention relates to a one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure and a technological method. The one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure is characterized in that a metal substrate frame is included, a paddle and pins are arranged in the metal substrate frame, the front face of the paddle and the front faces of the pins are aligned with the front face of the metal substrate frame, the back faces of the pins are aligned with the back face of the metal substrate frame, the back face of the paddle is aligned with the step faces of the pins, metal layers are arranged on the step faces of the pins, a chip is arranged on the back face of the paddle through conducting or non-conducting adhesion substances, the front face of the chip is connected with the surfaces of the metal layers on the step faces of the pins through metal wires, plastic packaging materials wrap the paddle, the pins, the chip and the metal wires, the plastic packaging materials are aligned with the upper surface and the lower surface of the metal substrate frame, and anti oxidation layers are plated on or organic solderability preservative (OSP) wraps the front face of the paddle, the front faces and the back faces of the pins and the surface of the metal substrate frame. The one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure has the advantages of being capable of solving the problem that the function and the application of a metal wire frame are restricted due to the fact that objects cannot be buried in the thickness of the traditional metal wire frame.

Owner:JCET GROUP CO LTD

Packaging-prior-to-etching type three-dimensional system-level chip-flipped packaging structure and process method thereof

ActiveCN103400776AHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

The invention relates to a packaging-prior-to-etching type three-dimensional system-level chip-flipped packaging structure and a process method thereof. The structure comprises a pad and pins, wherein a first chip is arranged on the front surface of the pad; second chips are flipped on the back surfaces of the pad and the pins through bottom filling adhesives; the front surfaces of the first chip and the pins are connected through metal wires; conductive columns are arranged on the front surfaces of the pins; molding compounds are encapsulated in the peripheral area of the pad, the areas between the pad and the pins and between each two pins, the upper areas of the pad and the pins, the lower areas of the pad and the pins, and the external areas of the first chip, the second chips, the metal wires and the conductive columns; and anti-oxidation layers are plated on the surfaces, exposed from the molding compounds, of the pins and the conductive columns. By virtue of the packaging-prior-to-etching type three-dimensional system-level chip-flipped packaging structure and the process method thereof, the problem of limitation of the functionality and application performance of a metal lead frame caused by difficulty in embedding of an object into a conventional metal lead frame can be solved.

Owner:江苏尊阳电子科技有限公司

Subtractive Buried Chip Flip-Chip Pin Structure and Process Method

ActiveCN103646936BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingLead frame

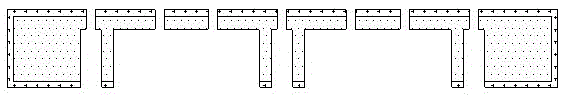

The invention relates to a secondary plating-prior-to-etching metal frame subtraction imbedded chip flip flat pin structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The pins (3) are in step shapes. The back surface of each base island (2) is flush with the step surface of each pin (3). The back surface of each base island (2) and the step surface of each pin (3) are invertedly equipped with a chip (6) through bottom filling glue (5). The metal substrate fame (1) is internally filled with plastic packaging material (7). The front surface of the plastic packaging material (7) is flush with the step surface of the pin (3). The back surface of the plastic packaging material (7) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (4). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame with such plate thickness is solved.

Owner:JCET GROUP CO LTD

Secondary etching-prior-to-plating metal frame subtraction imbedded chip flip flat pin structure and process method

ActiveCN103646930AAchieve privacyChieve protectiveSemiconductor/solid-state device detailsSolid-state devicesEtchingPlastic packaging

The invention relates to a secondary etching-prior-to-plating metal frame subtraction imbedded chip flip flat pin structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The pins (3) are in step shapes. The back surface of each base island (2) is flush with the step surface of each pin (3). The back surface of each base island (2) and the step surface of each pin (3) are invertedly equipped with a chip (6) through bottom filling glue (5). The metal substrate fame (1) is internally filled with plastic packaging material (7). The front surface of the plastic packaging material (7) is flush with the step surface of each pin (3). The back surface of the plastic packaging material (7) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (4). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame with such plate thickness is solved.

Owner:JCET GROUP CO LTD

Metal frame subtractive buried chip flip-chip flat pin structure and process method after etching once

ActiveCN103681581BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesThick plateAdhesive

The invention relates to a flip chip one-time etching combined type flat pin metal frame structure and a technological method thereof. The metal frame structure is characterized in that a metal base plate frame is included, base islands and pins are arranged inside the metal base plate frame, and chips are arranged on the back faces of the base islands and the step surfaces of the pins through underfill adhesives; the areas on the peripheries of the base islands, the areas between the base islands and the pins, the areas between the pins, the areas on the upper portions of the base islands and the pins, the areas on the lower portions of the base islands and the pins, and the outsides of the chips are all coated with molding compounds in a sealing mode; the molding compounds are flush with the upper surface and the lower surface of the metal base plate frame; anti oxidation layers are plated on or organic solderability preservative (OSP) wraps the front faces of the base islands, the front faces and the back faces of the pins and the surface of the metal base plate frame. The metal frame structure and the technological method thereof have the advantage of being capable of solving the problem that an object can not be embedded into a thick plate in a traditional metal lead frame, so that the functionality and application performance of the metal lead frame are limited.

Owner:JCET GROUP CO LTD

Secondary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation flat pin structure and process method

ActiveCN103646934AInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingLead frame

The invention relates to a secondary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation flat pin structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The pins (3) are in step shapes. The back surface of each base island (2) is flush with the step surface of each pin (3). The step surface of each pin (3) is provided with a metal layer (4). The back surface of each base island (2) is normally equipped with a chip (6). The surface of the chip (6) is connected with the surface of the metal layer (4) through a metal line (7). The metal substrate fame (1) is internally filled with plastic packaging material (8). The front surface of the plastic packaging material (8) is flush with the step surface of the pin (3). The back surface of the plastic packaging material (8) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (9). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame is solved.

Owner:JCET GROUP CO LTD

Twice first plating and then etching metal frame subtractive buried chip flip-chip bump structure and process method

ActiveCN103646935BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingOxidation resistant

Owner:JCET GROUP CO LTD

Convex point packaging structure and technique of horizontal chip of firstly-etched and then-packaged three-dimensional system level

ActiveCN103390567AHigh functional integrationImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingLead frameMetal

The invention relates to a convex point packaging structure and a technique of a horizontal chip of a firstly-etched and then-packaged three-dimensional system level. The structure comprises pads and pins, wherein first chips and second chips are arranged on front sides and rear sides of the pads; front sides of the first chips and the second chips are connected with the front sides and the rear sides of the pins through metal wires respectively; conductive columns are arranged on the front sides of the pins; the peripheral areas of the pads, the areas between the pads and the pins and among the pins, the areas of the upper parts and the lower parts of the pads and the pins and outsides of the first chips, the second chips, the metal wires and the conductive columns are packaged with a molding compound; surfaces, exposing out the molding compound, of the conductive columns are plated with an anti-oxidation layer; and metal balls are arranged at the tops of the conductive columns. According to the convex point packaging structure and the technique of the horizontal chip of the firstly-etched and then-packaged three-dimensional system level, the problem that the integration of a whole packaging function is limited due to the fact that an object cannot be embedded into a conventional metal lead frame or an organic multilayer circuit substrate is solved.

Owner:江阴芯智联电子科技有限公司

Subtractive buried chip front-mounted flat leg structure and process method of metal frame plating after secondary etching

ActiveCN103681579BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention relates to a secondary first-corrosion-then-plating metal frame subtraction burying chip obverse-mounting flat foot structure and technology method. The structure comprises a metal base plate frame (1), a base island (2) and a pin (3) are arranged in the metal base plate frame (1), the pin (3) is in a step shape, the back face of the base island (2) and the step face of the pin (3) are flush, a metal layer (4) is arranged on the step face of the pin (3), a chip (6) is arranged on the back face of the base island (2) in an obverse mode, the surface of the chip (6) and the surface of the metal layer (4) are connected through a metal wire (7), the inner zone of the metal base plate frame (1) is filled with moulding compounds (8), the front face of the moulding compounds (8) is flush with the step face of the pin (3), the back face of the moulding compounds (8) is flush with the back face of the metal base plate frame (1), and anti-oxidation layers (9) are arranged on the front face of the base island (2), the front face and the back face of the pin (3) and the front face and the back face of the metal base plate frame (1). The structure has the advantages that the problem that an object cannot be buried into plate thickness of a traditional metal lead frame, so that the function and the application performance of the metal lead frame are limited can be solved.

Owner:JCET GROUP CO LTD

Secondary plating-prior-to-etching metal frame subtraction imbedded chip flip bump structure and process method

ActiveCN103646935AAchieve privacyChieve protectiveSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingOxidation resistant

The invention relates to a secondary plating-prior-to-etching metal frame subtraction imbedded chip flip bump structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The pins (3) are in step shapes. The back surface of each base island (2) is flush with the step surface of each pin (3). The back surface of each base island (2) and the step surface of each pin (3) are invertedly equipped with a chip (6) through bottom filling glue (5). The metal substrate fame (1) is internally filled with plastic packaging material (7). The front surface of the plastic packaging material (7) is flush with the step surface of the pin (3). The back surface of the plastic packaging material (7) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (4). The back surface of each pin (3) is provided with a metal ball (9). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame with such plate thickness is solved.

Owner:JCET GROUP CO LTD

Metal frame subtractive embedded chip structure and process method

ActiveCN103681583BSmall sizeLow costSemiconductor/solid-state device detailsSolid-state devicesWire frameMetal substrate

The invention relates to a one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure and a technological method. The one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure is characterized in that a metal substrate frame is included, a paddle and pins are arranged in the metal substrate frame, the front face of the paddle and the front faces of the pins are aligned with the front face of the metal substrate frame, the back faces of the pins are aligned with the back face of the metal substrate frame, the back face of the paddle is aligned with the step faces of the pins, metal layers are arranged on the step faces of the pins, a chip is arranged on the back face of the paddle through conducting or non-conducting adhesion substances, the front face of the chip is connected with the surfaces of the metal layers on the step faces of the pins through metal wires, plastic packaging materials wrap the paddle, the pins, the chip and the metal wires, the plastic packaging materials are aligned with the upper surface and the lower surface of the metal substrate frame, and anti oxidation layers are plated on or organic solderability preservative (OSP) wraps the front face of the paddle, the front faces and the back faces of the pins and the surface of the metal substrate frame. The one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged flat foot structure has the advantages of being capable of solving the problem that the function and the application of a metal wire frame are restricted due to the fact that objects cannot be buried in the thickness of the traditional metal wire frame.

Owner:JCET GROUP CO LTD

Metal frame subtractive embedded chip structure and process method

ActiveCN103646929BAchieve privacyChieve protectiveSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingAntioxidant

The invention relates to a primary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation flat pin structure and a process method. The structure comprises a metal substrate frame. The metal substrate frame is internally provided with base islands and pins. The pins are in step shapes. The front surface of each base island and the front surface of each pin are flush with the front surface of the metal substrate frame. The back surface of each pin is flush with the back surface of the metal substrate frame. The back surface of each base island is flush with the step surface of each pin. The step surface of each pin is provided with a metal layer. The back surface of each base island is provided with a chip through conductive or non-conductive bonding material. The front surface of the chip is connected with the surface of the metal layer on the step surface of each pin through a metal line. The front surface of the base island, the front surface and the back surface of each pin as well as the surface of the metal substrate frame are plated with an anti-oxidation layer or a coated antioxidant (OSP), wherein plastic packaging materials are flush with the anti-oxidation layers or coated antioxidants (OSP) on the upper and lower surfaces of the metal substrate frame. The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame of such plate thickness is solved.

Owner:JCET GROUP CO LTD

One-time plating first and then etching metal frame subtractive buried chip front-mount bump structure and process method

ActiveCN103646932BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingMetallurgy

The invention relates to a primary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation bump structure and a process method. The structure is characterized in that the structure comprises a metal base frame; the metal base frame is internally provided with base islands and pins; the pins are in step shapes; the front surface of each base island and the front surface of each pin are flush with the front surface of the metal substrate frame; the back surface of each pin is flush with the back surface of the metal substrate frame; the step surface of each pin is provided with a metal layer; the back surface of each base island is provided with a chip through a conductive or non-conductive bonding material; the front surface of the chip is connected with the surface of the metal layer through a metal line; the front surface of the base island, the front surface and the back surface of each pin as well as the surface of the metal substrate frame are plated with an anti-oxidation layer or a coated antioxidant (OSP), wherein plastic packaging materials are flush with the anti-oxidation layers or the coated antioxidants (OSP) on the upper and lower surfaces of the metal substrate frame; and the back surface of each pin is provided with a metal ball. The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame of such plate thickness is solved.

Owner:JCET GROUP CO LTD

Subtractive Buried Chip Flip-Chip Flat Pin Structure and Process Method

ActiveCN103646930BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEtching

The invention relates to a secondary etching-prior-to-plating metal frame subtraction imbedded chip flip flat pin structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The pins (3) are in step shapes. The back surface of each base island (2) is flush with the step surface of each pin (3). The back surface of each base island (2) and the step surface of each pin (3) are invertedly equipped with a chip (6) through bottom filling glue (5). The metal substrate fame (1) is internally filled with plastic packaging material (7). The front surface of the plastic packaging material (7) is flush with the step surface of each pin (3). The back surface of the plastic packaging material (7) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (4). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame with such plate thickness is solved.

Owner:JCET GROUP CO LTD

One-time etch first and then plate metal frame subtractive embedded chip front-mount bump structure and process method

ActiveCN103681582BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesEtchingPlastic packaging

Owner:JCET GROUP CO LTD

Primary plating-prior-to-etching metal frame subtraction imbedded chip flip plat pin structure and process method

ActiveCN103646931AInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention relates to a primary plating-prior-to-etching metal frame subtraction imbedded chip flip plat pin structure and a process method. The primary plating-prior-to-etching metal frame subtraction imbedded chip flip plat pin structure is characterized in that the structure comprises a metal base frame; the metal base frame is internally provided with base islands and pins; the back surface of each base island and the step surface of each pin are invertedly provided with a chip through bottom filling glue; the peripheral areas of the base islands, the areas between the base islands and the pins, the areas between the pins, the areas above the base islands and the pins, the areas under the base islands and the pins and the outer sides of the chips are wrapped with plastic packaging materials; and the front surface of the base island, the front surface and the back surface of each pin as well as the surface of the metal substrate fame are plated with an anti-oxidation layer or a coated antioxidant (OSP), wherein the plastic packaging materials are flush with the anti-oxidation layers or coated antioxidants (OSP) on the upper and lower surfaces of the metal substrate fame. The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame of such plate thickness is solved.

Owner:JCET GROUP CO LTD

Seal first and etch later three-dimensional system-level chip flip-chip bump packaging structure and process method

ActiveCN103400775BHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEpoxyWire width

The invention relates to a packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and a process method thereof. The packaging structure comprises a pad (1) and pins (2), wherein conductive columns (3) are arranged on the front surfaces of the pins (2); a first chip (4) is normally bonded on the front surface of the pad (1); first molding compounds or epoxy resins (9) are encapsulated in the peripheral areas of the conductive columns (3), the first chip (4) and a first metal wire (5); second chips (7) are flipped on the back surfaces of the pad (1) and the pins (2); second molding compounds or epoxy resins (10) are encapsulated in the back areas of the pad (1) and the pins (2) and the peripheral areas of the second chips (7); and first metal balls (17) are arranged on the conductive columns (3). By virtue of the packaging-prior-to-etching type three-dimensional system-level chip-flipped bump packaging structure and the process method thereof, the problems of limitation of the whole packaging functional integrity caused by difficulty in embedding of an object into a conventional metal lead frame or a conventional organic substrate and requirements on smaller wire width and smaller wire interval of the conventional organic substrate can be solved.

Owner:江苏尊阳电子科技有限公司

Etch first and then seal three-dimensional system-level chip flip-chip bump packaging structure and process method

ActiveCN103400769BHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesAdhesiveFunctional integrity

Owner:江苏尊阳电子科技有限公司

Primary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation flat pin structure and process method

ActiveCN103646929AInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

Owner:JCET GROUP CO LTD

Etch first and then seal three-dimensional system-on-chip front-mount bump packaging structure and process method

ActiveCN103390567BHigh functional integrationImprove cooling effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLead frame

Owner:江阴芯智联电子科技有限公司

Secondary first plating and then etching metal frame subtraction embedded chip positive bump structure and process method

ActiveCN103646939BInterference with control signal transmissionSmall sizeSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingOxidation resistant

The invention relates to a secondary plating-prior-to-etching metal frame subtraction imbedded chip normal-installation bump structure and a process method. The structure comprises a metal substrate fame (1). The metal substrate fame (1) is internally provided with base islands (2) and pins (3). The back surface of each base island (2) is flush with the step surface of each pin (3). The step surface of each pin (3) is provided with a metal layer (4). The back surface of each base island (2) is normally equipped with a chip (6). The surface of the chip (6) is connected with the surface of the metal layer (4) through a metal line (7). The metal substrate fame (1) is internally filled with plastic packaging material (8). The front surface of the plastic packaging material (8) is flush with the step surface of the pin (3). The back surface of the plastic packaging material (8) is flush with the back surface of the metal substrate fame (1). The front surface of the base island (2), the front surface and the back surface of each pin (3) as well as the front surface and the back surface of the metal substrate fame (1) are provided with an anti-oxidation layer (9). The back surface of each pin (3) is provided with a metal ball (10). The beneficial effect of the structure and method is that: the problem that the function and the application performance of a conventional metal lead frame are limited since an object cannot be imbedded in the metal lead frame is solved.

Owner:JCET GROUP CO LTD

One-time eroding-before-plating metal frame subtraction embedded chip normally-arranged salient point structure and technological method

ActiveCN103681582AAchieve privacyChieve protectiveSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingStructure of the Earth

The invention relates to a one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged salient point structure and a technological method. The one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged salient point structure is characterized in that a metal substrate frame is included, a paddle and pins are arranged in the metal substrate frame, the pins are of a step shape, the front face of the paddle and the front faces of the pins are aligned with the front face of the metal substrate frame, the back faces of the pins are aligned with the back face of the metal substrate frame, the back face of the paddle is aligned with the step faces of the pins, metal layers are arranged on the step faces of the pins, a chip is arranged on the back face of the paddle through conducting or non-conducting adhesion substances, the front face of the chip is connected with the surfaces of the metal layers on the step faces of the pins through metal wires, plastic packaging materials wrap the paddle, the pins, the chip and the metal wires, and anti oxidation layers are plated on or organic solderability preservative (OSP) wraps the front face of the paddle, the front faces and the back faces of the pins and the surface of the metal substrate frame. Metal balls are arranged on the back faces of the pins. The one-time eroding-before-plating metal frame subtraction embedded chip normally-arranged salient point structure has the advantages of being capable of solving the problem that the function and the application performance of a metal wire frame are restricted due to the fact that objects cannot be buried in the thickness of the traditional metal wire frame.

Owner:JCET GROUP CO LTD

Etching first and then sealing three-dimensional system-on-chip flip-chip packaging structure and process method

ActiveCN103400776BHigh functional integrationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

The invention relates to a packaging-prior-to-etching type three-dimensional system-level chip-flipped packaging structure and a process method thereof. The structure comprises a pad and pins, wherein a first chip is arranged on the front surface of the pad; second chips are flipped on the back surfaces of the pad and the pins through bottom filling adhesives; the front surfaces of the first chip and the pins are connected through metal wires; conductive columns are arranged on the front surfaces of the pins; molding compounds are encapsulated in the peripheral area of the pad, the areas between the pad and the pins and between each two pins, the upper areas of the pad and the pins, the lower areas of the pad and the pins, and the external areas of the first chip, the second chips, the metal wires and the conductive columns; and anti-oxidation layers are plated on the surfaces, exposed from the molding compounds, of the pins and the conductive columns. By virtue of the packaging-prior-to-etching type three-dimensional system-level chip-flipped packaging structure and the process method thereof, the problem of limitation of the functionality and application performance of a metal lead frame caused by difficulty in embedding of an object into a conventional metal lead frame can be solved.

Owner:江苏尊阳电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com