Fast production of high-purity radix ligustici sinensis lactone

A high-purity technology for ligustilide, applied in the field of rapid preparation of high-purity ligustilide, can solve the problems of uncommon, cumbersome detection methods, low production efficiency, etc., and achieve convenient and accurate identification methods, strong scientific and Exclusiveness, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

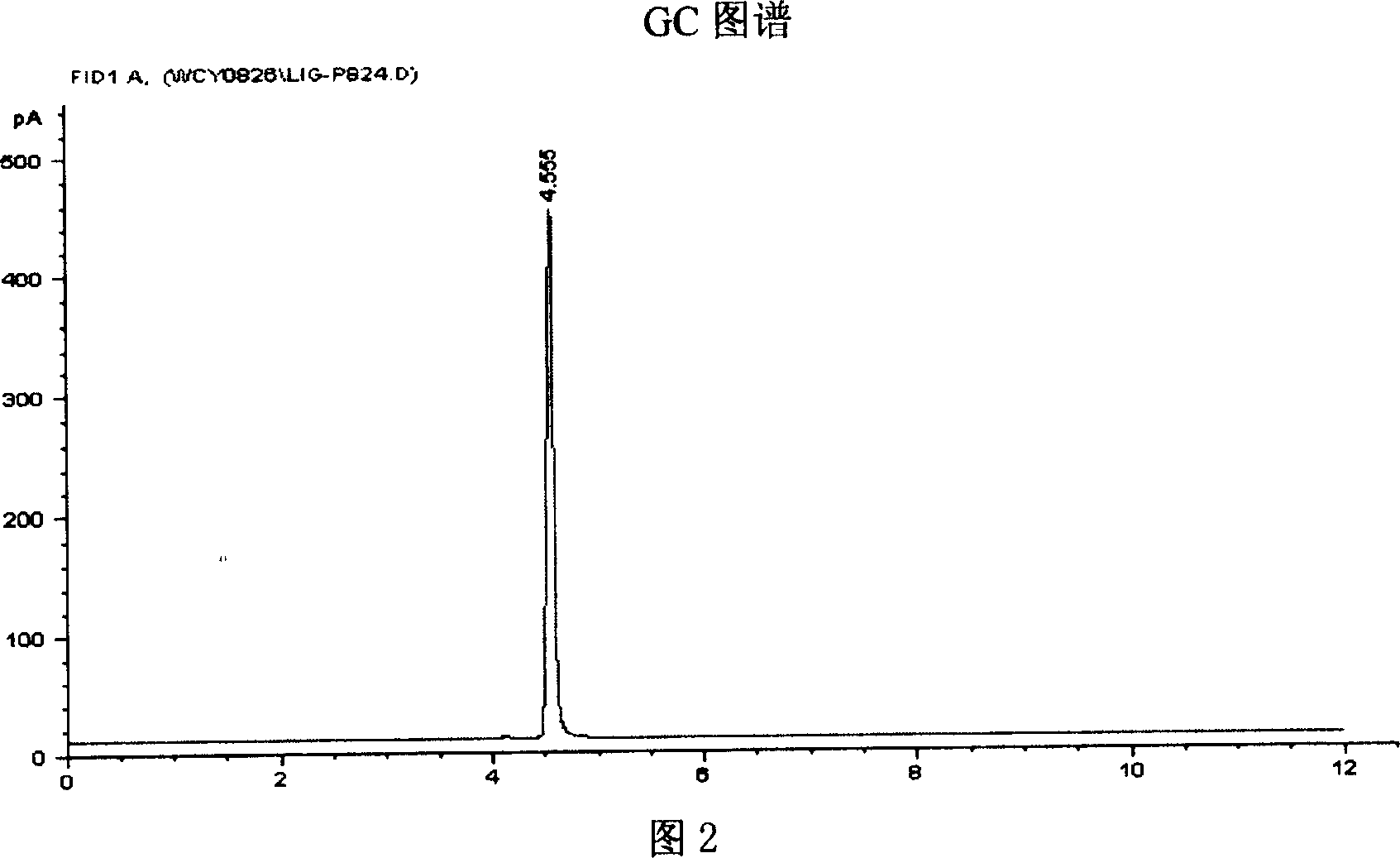

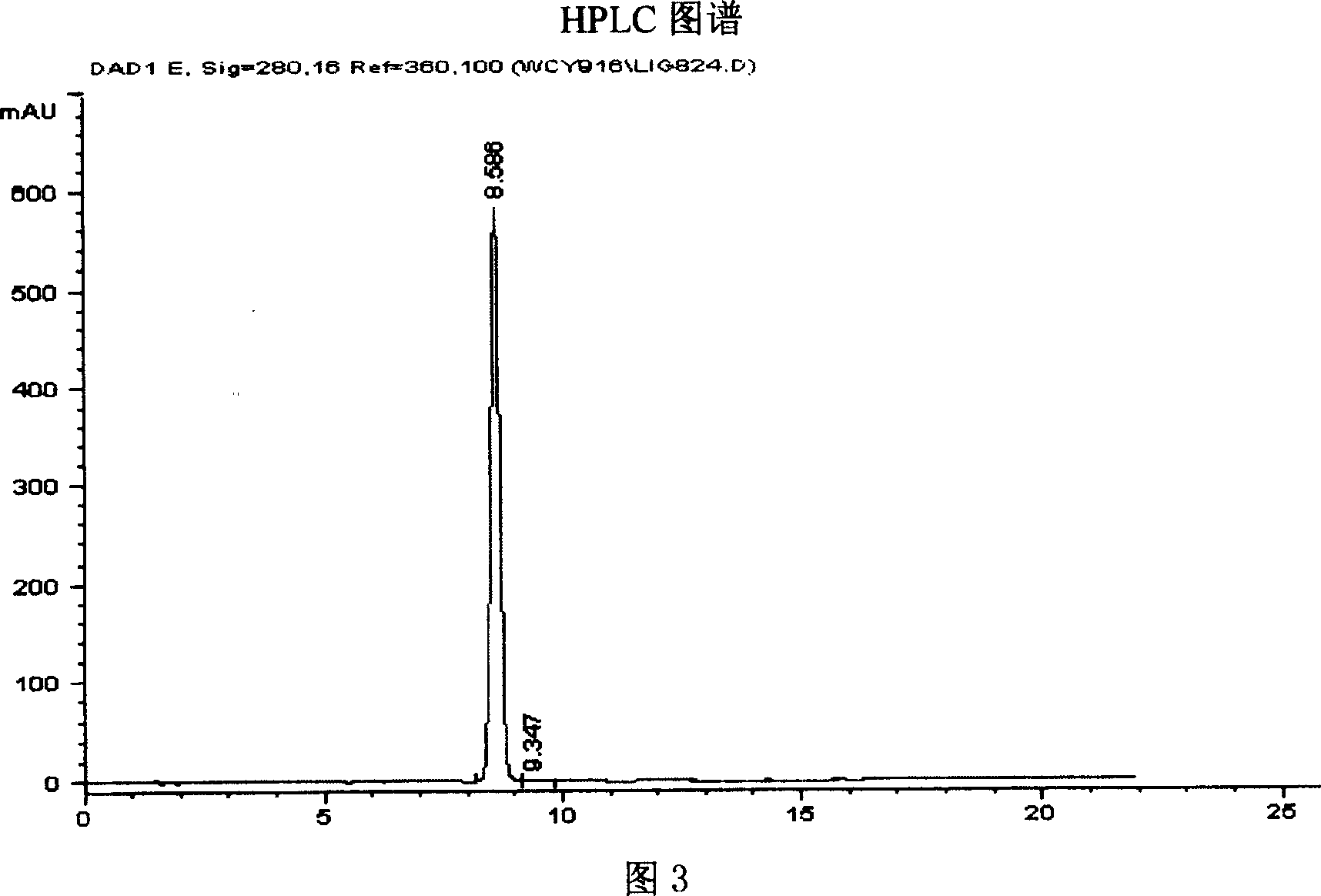

Examples

Embodiment 1

[0064] (1) Extraction and separation:

[0065] Extract ligustilide crude oil with ethanol reflux extraction method: weigh 20kg of angelica crude drug and chop it properly, add 8 times the amount of 95% ethanol to soak overnight in the extraction tank, heat and reflux extraction for 2 hours, filter, and separate the drug residues Add 6 times and 6 times the amount of 95% ethanol, heat and reflux for extraction for 2 hours respectively, filter and combine the filtrates, concentrate the filtrate under reduced pressure to recover the ethanol, and obtain about 800ml of dark brown thick liquid crude oil.

[0066] Mix the sample with 0.6kg of silica gel (100-200 mesh). Use a short thick column (diameter 25cm) to take 6kg of chromatography silica gel (200-300 mesh) and add silica gel while pumping with a water pump, and make it fully tightened so that the top surface is flat, and the height of the silica gel surface is about 30cm. Put the mixed sample silica gel on the short and thic...

Embodiment 2

[0089] Using 300-400 mesh silica gel, take 3 parts of 50ml of the same angelica volatile oil (the content of ligustilide is about 30%) respectively, add 50g of silica gel (80-100 mesh) to mix the samples respectively, and use vacuum column chromatography, Three different separation methods, such as normal pressure column chromatography and pressurized column chromatography, use the same petroleum ether-ethyl acetate elution system to complete a separation. The specific test is as follows:

[0090] Decompression column chromatography separation: use a sand core funnel (diameter 12.5cm) to take 250g of chromatography silica gel (300-400 mesh) and add silica gel while pumping with a water pump, and make it fully tightened so that the top surface is flat. The surface height is 5cm. Load the mixed sample on the top of the column, suck it with a water pump, first add 1L of petroleum ether to wash, and then wash with 4L of petroleum ether-ethyl acetate (30:1), 200ml (about 1 / 3 of th...

Embodiment 3

[0097] Ethanol leaching method to extract crude oil: Weigh 10kg of angelica crude drug and chop it properly, add 1 times the amount of 95% ethanol to moisten it, add it to the percolation irrigation, continue to add 2 times the amount of 95% ethanol, soak overnight, and then continue to add 15 times the amount of 95% ethanol was percolated at a drop rate of 1ml / kg.min, the leachate was collected, and concentrated under reduced pressure to obtain a crude oil of about 380ml of dark brown thick liquid.

[0098] The obtained crude oil was appropriately diluted with 400 ml of n-hexane. Use a sand core funnel (diameter 25cm) to take 3kg of chromatography silica gel (100-200 mesh) and add silica gel while pumping with a water pump, and make it fully tightened so that the top surface is flat, and the height of the silica gel surface is 12cm. Put the diluted sample on the silica gel column that has been installed, suck it with a water pump, first add 5L of n-hexane to rinse, then add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com