Thermosetting resin composition, presoaking materials and laminated sheet for printed circuit using same

A resin composition and thermosetting technology, which is applied in the direction of synthetic resin layered products, layered products, textiles and papermaking, etc., and can solve problems such as large amount of smoke, environmental pollution, and unpleasant smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

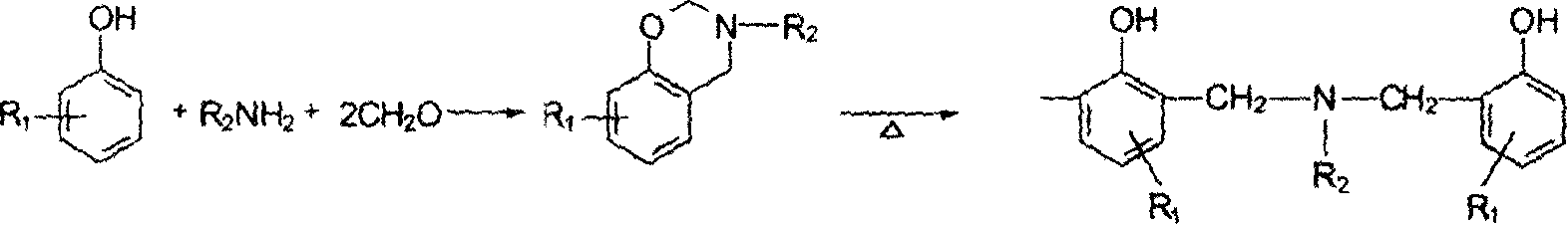

[0016] A kind of thermosetting resin composition of the present invention is by (A), (B), (C), (D) four kinds of components are combined, with the organic solid content of the composition in the composition of the present invention by weight percentage 100 In terms of parts, thermosetting resins with phosphorus-containing epoxy resin as the main component account for 46 to 70 parts by weight, compounds with dihydrobenzoxazines account for 20 to 44 parts by weight, phenols and compounds with triazine rings and The polycondensate of aldehydes accounts for 2 to 9 parts by weight and contains 0.1 to 1.0 parts by weight of accelerator, which is one or more mixtures of imidazole or methylimidazole or methyl or ethylimidazole.

[0017] The (A) component is a thermosetting resin with phosphorus epoxy resin as the main component. In the composition of the present invention, the total amount of organic solids is 100 parts by weight, and it is preferably 46 to 70 parts by weight. 55 to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com