Method for improving the bonding strength between nickel or nickel alloy cast layers in laminated micro devices

A combination strength and micro-device technology, which is applied in chemical instruments and methods, microstructure technology, microstructure devices, etc., can solve the problems that the requirements of high bonding strength cannot be fully met, the process reproducibility is poor, and the bonding strength between layers is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

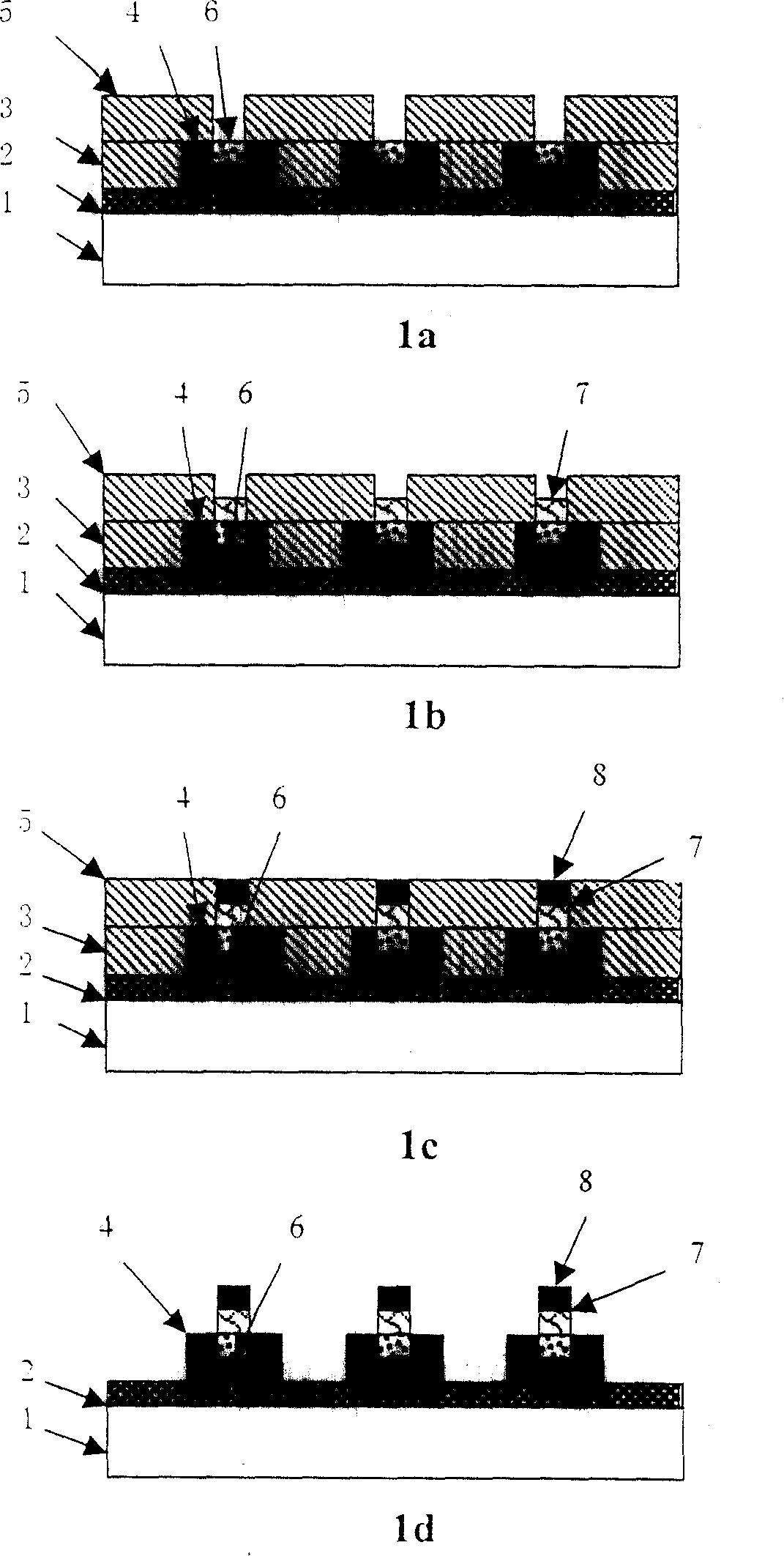

[0021] Embodiment 1 electroforming nickel to make double-layer microgear

[0022] Such as figure 1 shown, according to figure 1 For implementation, due to the special requirements on the structure of the double-layer micro-gear, UV-LIGA technology is used for micro-processing. That is, on the glass substrate 1, the Cr / Cu seed layer 2 is sputtered, the first layer of photoresist 3 is formed by spraying glue and photolithography, and then the first layer of nickel casting is obtained after mask electroforming and polishing. Layer 4; on it, a second layer of photoresist 5 is formed by lithography and photolithography; then activation-AC transition plating is performed. The treatment liquid this time uses NiSO 4 ·6H 2 O 120g / l, NiCl 2 ·6H 2 O 120g / l, HCl 100g / l and sodium 1,3,6-naphthalenetrisulfonate 0.05g / l, the pH was adjusted to 1.0, and the treatment temperature was 45°C.

[0023] 1) if figure 1 a cathode and anode alternate etching treatment: anode current density 7A...

Embodiment 2

[0027] Embodiment 2 Electroformed double-layer nickel-iron alloy

[0028] Thickness 0.3mm, area 1.5×1.5cm 2 Experiments on the bonding force of electroformed double-layer nickel-iron alloys on copper sheets. After the copper substrate 1 is degreased and polished, a 100 μm nickel-iron alloy cast layer 4 is plated in a sulfate-based nickel-iron alloy electroplating solution. After being placed in the atmosphere for 24 hours, secondary nickel-iron alloy electroforming is performed. The solution used in the activation treatment is made of NiCl 2 ·6H 2 O 100g / l, FeCl 2 4H 2 O 10g / l, HCl 20g / l and sodium dodecyl sulfonate 0.01g / l, adjust the pH to 1.5, and the temperature is 50°C; immerse the nickel-iron-plated test piece in the above solution for activation treatment.

[0029] first step, such as figure 1 a cathode and anode alternate etching treatment: anode current density 3A / dm 2, pulse period 1ms, cathode current density 1.5A / dm 2 , the pulse period is 1ms, the etching ...

Embodiment 3

[0033] Embodiment 3 Electroformed double-layer nickel

[0034] Thickness 0.3mm, area 1.5×1.5cm 2 Electroformed double-layer nickel adhesion experiments on copper sheets. Firstly, the copper substrate 1 is degreased and polished, and then a nickel casting layer 4 of 100 μm is plated in a nickel sulfamate plating solution, and placed in the atmosphere for 24 hours, followed by secondary nickel electroforming. The solution used in the activation treatment before the secondary electroforming is made of NiCl 2 ·6H 2 O 150g / l, HCl 50g / l and sodium dodecylsulfonate 0.01g / l, the pH is adjusted to 1.2, and the temperature is 50°C; the primary nickel-plated test piece is immersed in the above solution.

[0035] first step, such as figure 1 a cathode and anode alternate etching treatment: anode current density 5A / dm 2 , pulse period 10ms, cathode current density 2.5A / dm 2 , the pulse period is 10ms, the etching time is 5min, and the cathode and anode alternate etching layer 6 is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com