Cast rolling method and equipment of isometric crystal ferrite stainless steel slab band

A stainless steel plate and ferrite technology, applied in the field of axial crystal casting and rolling, can solve the problems of low equiaxed crystal rate, complicated control process, expensive equipment, etc., and achieve the effects of uniform temperature, improved purity and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

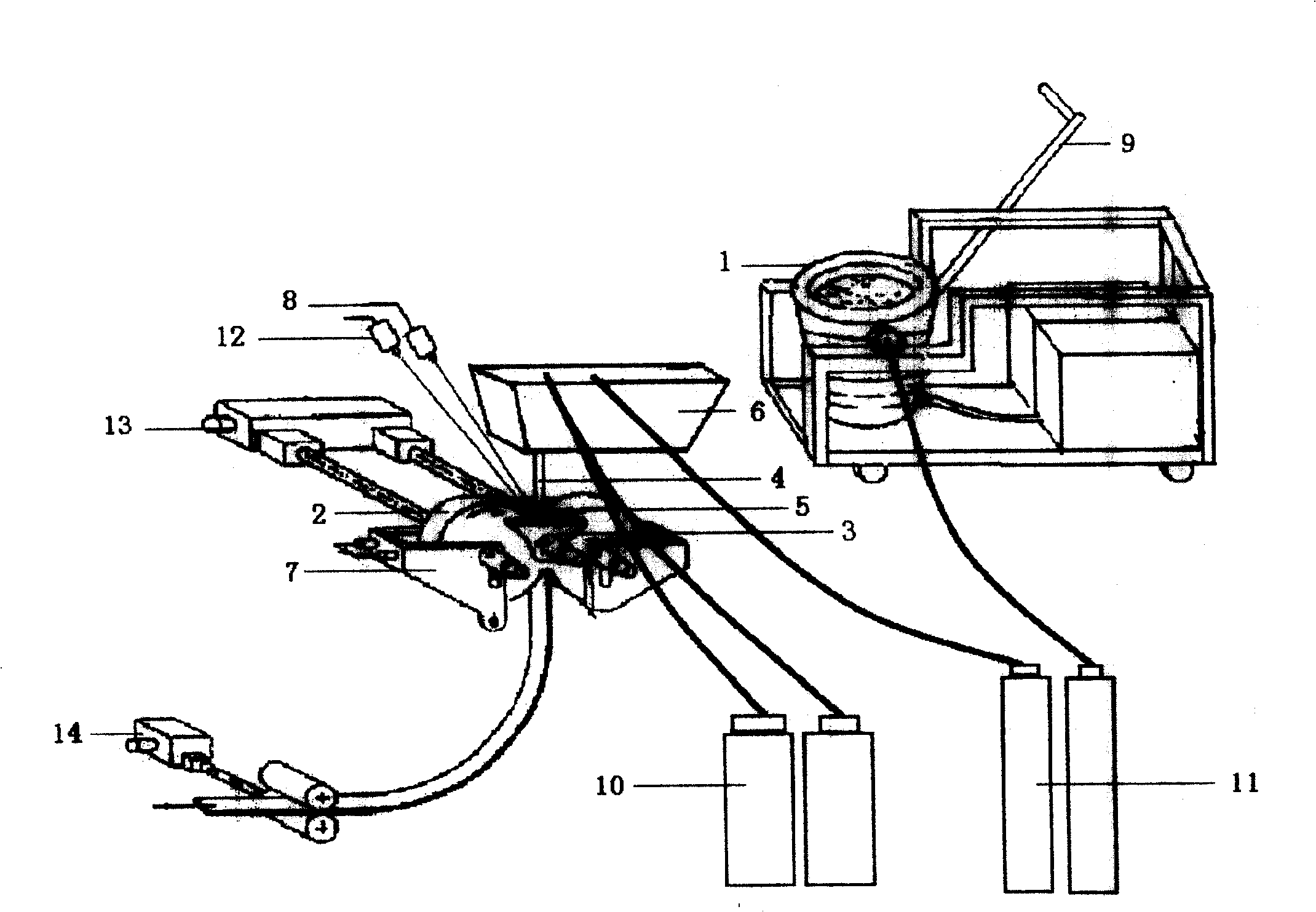

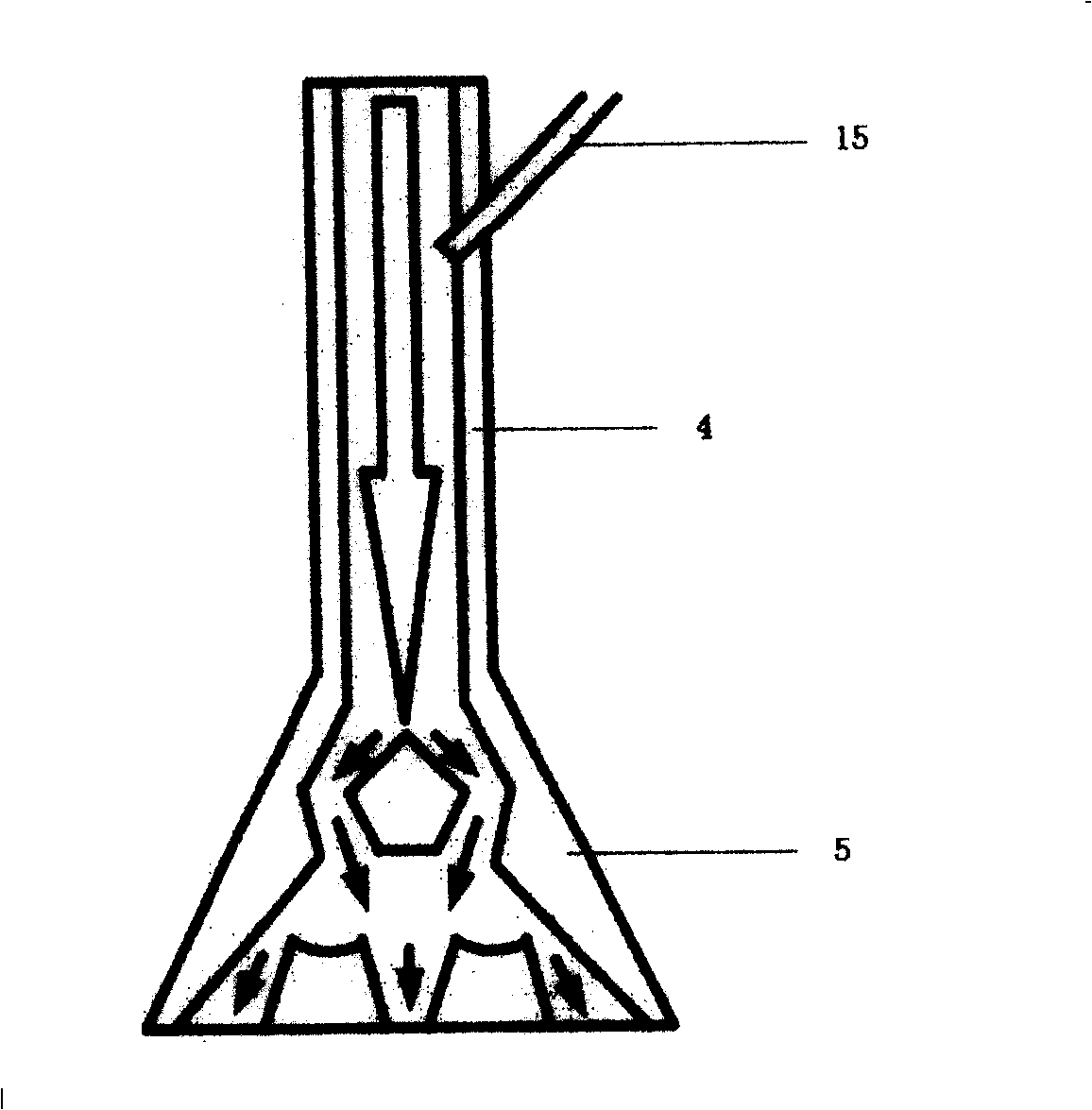

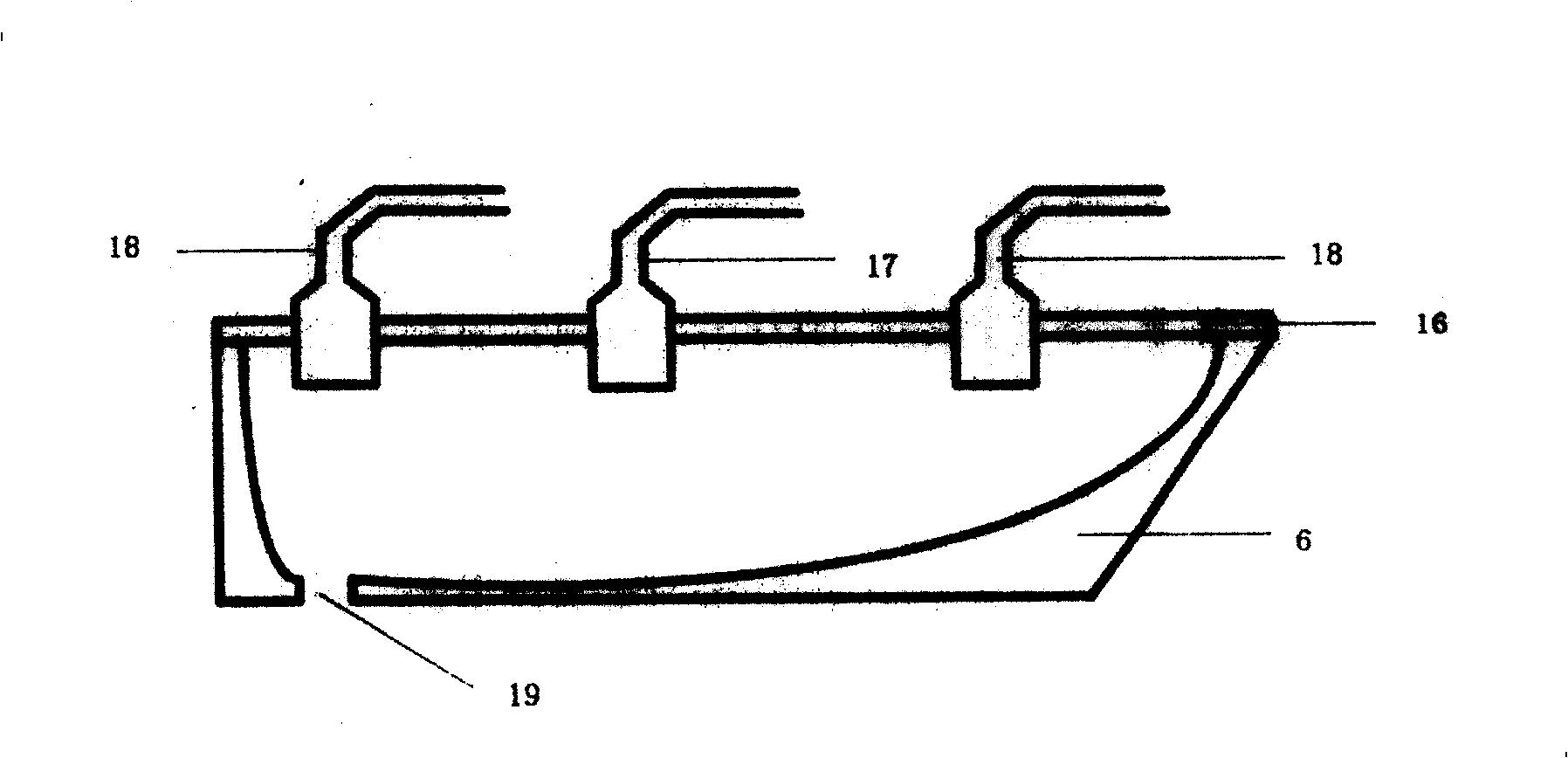

[0041] The chemical composition is: [C]≤0.12%, [Si]≤0.75%, [Mn]≤0.80%, [S]≤0.030%, [P]≤0.035%, [Cr]=16~18%, [Ni ]≤0.60%, Fe is the balance of ferritic stainless steel raw materials, after preheating, put into 40Kg intermediate frequency induction furnace 1, heating power is 10KW, when the temperature reaches 900 ℃, the gas supply device 11 to the induction furnace 1 The inert gas is introduced into the medium, and the melting is carried out under the inert protective gas. When the temperature reaches 1200°C, add DFC-700 stainless steel slagging agent, carry out stirring and refining for 5 minutes, and let air blow slag and let it stand for 5 minutes. Then, when the temperature reaches 1100°C, preheat the tundish 6, the gate 4, the spout 5, and the side sealing plate 3 for about 10 minutes. When the temperature of the liquid ferritic stainless steel reaches 1480°C, keep it warm for 10 minutes, pour it into the tundish 6 under the protection of inert gas, and the tundish 6 shou...

Embodiment 2

[0043] The chemical composition is: [C]≤0.1%, [Si]≤0.6%, [Mn]≤0.3%, [S]≤0.005%, [P]≤0.02%, [Cr]=11~11.5%, [Ti ] ≤ 0.5%, [Nb] ≤ 0.3%, Fe is the balance of the ferritic stainless steel raw material after preheating, put it into the 40Kg intermediate frequency induction furnace 1, the heating power is 25KW, when the temperature reaches 1050 ℃, by the gas supply The device 11 feeds an inert gas into the induction furnace 1 to carry out smelting under an inert protective gas. When the temperature reaches 1200°C, add DFC-700 stainless steel slagging agent, carry out stirring and refining for 15 minutes, blow the slag with 5 atmospheres of argon, and let it stand for about 15 minutes. Then, when the temperature reaches 1300°C, preheat the tundish 6, the gate 4, the spout 5, and the side sealing plate 3 for about 15 minutes. When the temperature of the liquid ferritic stainless steel reaches 1560°C, keep it warm for 10 minutes, pour it into the tundish 6 under the protection of inert...

Embodiment 3

[0045]The chemical composition is: [C]≤0.12%, [Si]≤0.75%, [Mn]≤0.80%, [S]≤0.030%, [P]≤0.035%, [Cr]=16~18%, [Ni ]≤0.60%, Fe is the balance of ferritic stainless steel raw materials, after preheating, put into 40Kg medium frequency induction furnace 1, heating power is 25KW, when the temperature reaches 1050 ℃, the gas supply device 11 to the induction furnace 1 The inert gas is introduced into the medium, and the melting is carried out under the inert protective gas. When the temperature reaches 1200°C, add DFC-700 stainless steel slagging agent, carry out stirring and refining for 15 minutes, and let air blow slag and let it stand for 15 minutes. Then, when the temperature reaches 1300°C, preheat the tundish 6, the gate 4, the spout 5, and the side sealing plate 3 for about 15 minutes. When the temperature of the liquid ferritic stainless steel reaches 1490°C, keep it warm for 10 minutes, pour it into the tundish 6 under the protection of inert gas, and the tundish 6 should k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com