A surface plasmon crystal and a preparation method thereof

A technology of surface plasmons and crystals, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve the problems of complex process, large equipment investment, high cost, etc., and achieve low equipment requirements and simple preparation process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

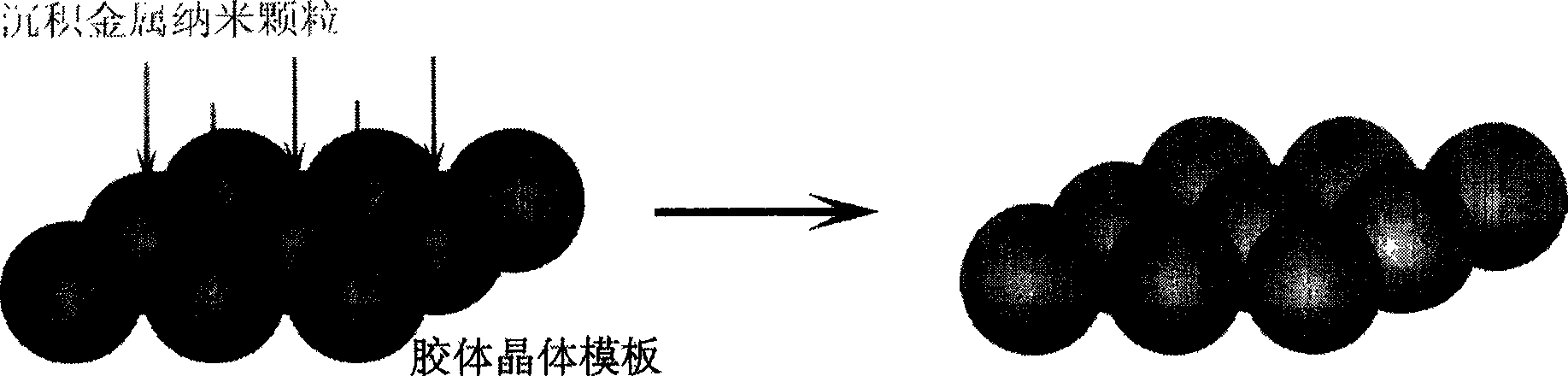

Method used

Image

Examples

Embodiment 1

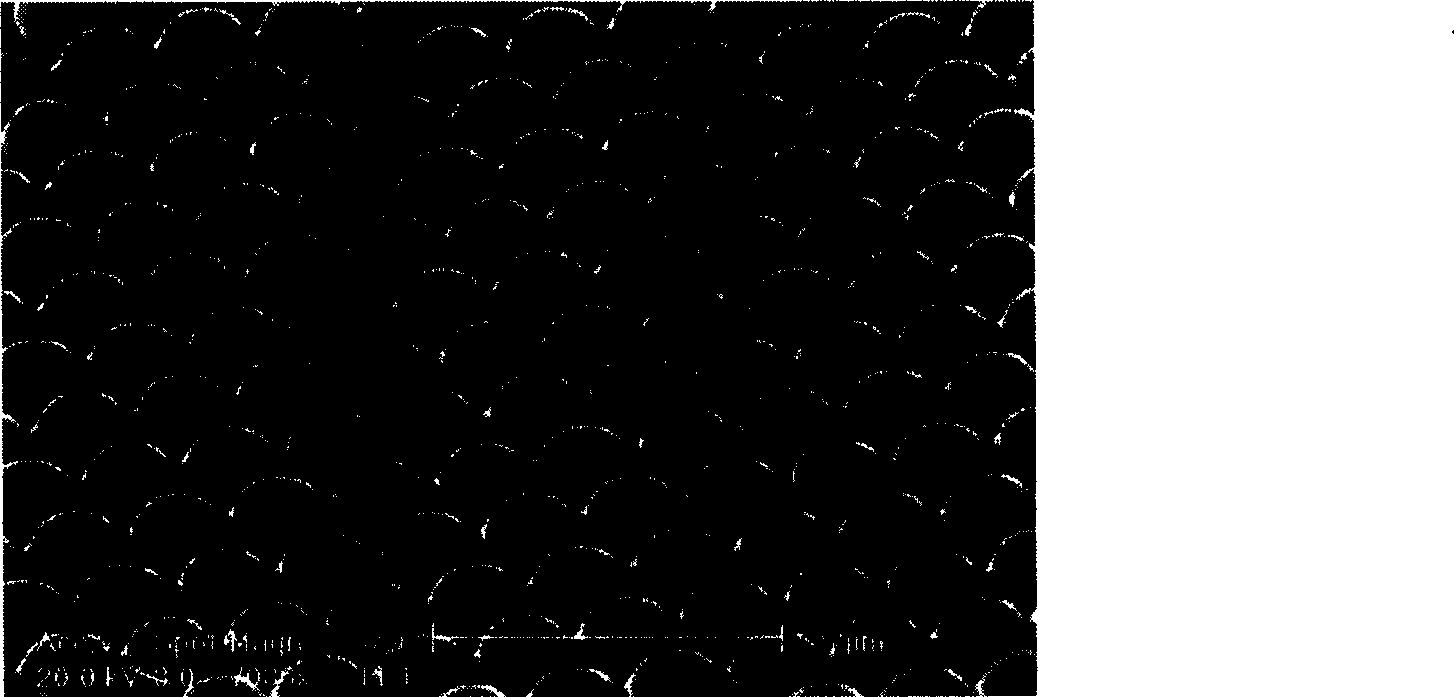

[0018] Embodiment 1: In this example, monodisperse silica microspheres are selected, and the diameter of the silica microspheres is 1580 nm. First, the microspheres are arranged into a hexagonal close-packed array by means of the surface tension in the microchannel (see microsphere self-organization technology, patent ZL 03 1 31989.0). Then, a layer of gold film was deposited on the surface of the microsphere by high vacuum argon ion beam sputtering method, and the deposition amount of gold particles was controlled so that the thickness of the apex of the gold shell layer was 25nm. Since each silica microsphere is covered with a hemispherical gold nanoshell, the hemispherical shell metals are connected to each other, thereby forming equal-diameter silica microspheres in contact with each other and deposited on them. A surface plasmon crystal composed of gold hemispherical shells on the surface.

Embodiment 2

[0019] Embodiment 2: This embodiment is basically the same as Embodiment 1, but the selected target material is a circular silver block with a diameter of 20 mm and a thickness of about 2 mm. Therefore, a surface plasmon crystal composed of equal-diameter silicon dioxide microspheres in contact with each other and a silver hemispherical shell deposited on the surface is formed, and the physical vapor deposition method is a metal thermal evaporation coating method.

Embodiment 3

[0020] Embodiment 3: This embodiment is basically the same as Embodiment 1, but as the medium microsphere array of the substrate, a two-dimensional ordered array of polystyrene microspheres is selected, and what is obtained is made of equal-diameter polystyrene microspheres in contact with each other. The surface plasmon crystal composed of spheres and chromium hemispherical shells deposited on the surface, the thickness of the metal film on the apex of the dielectric microsphere substrate surface is 150nm, and the physical vapor deposition method is laser pulse deposition method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com