Special charcoal-base slow release fertilizer for soybean and preparation method thereof

A special fertilizer and soybean technology, which is applied in the field of carbon-based slow-release soybean special fertilizer and its preparation, can solve the problems of lack of rich pores, adsorption capacity, and high cost, and achieve saving of fertilization costs and energy consumption, simple preparation process, and fertilizer The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

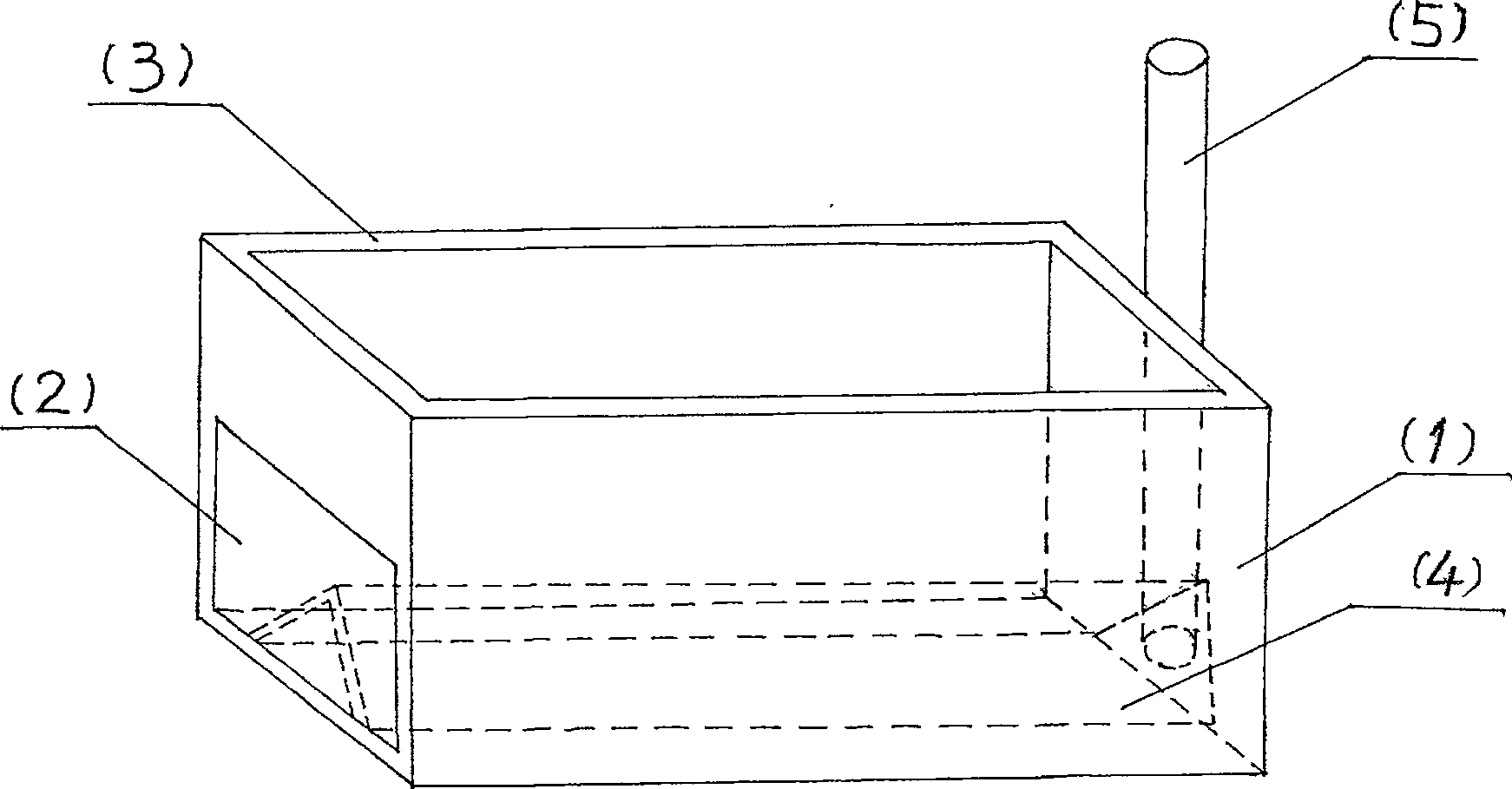

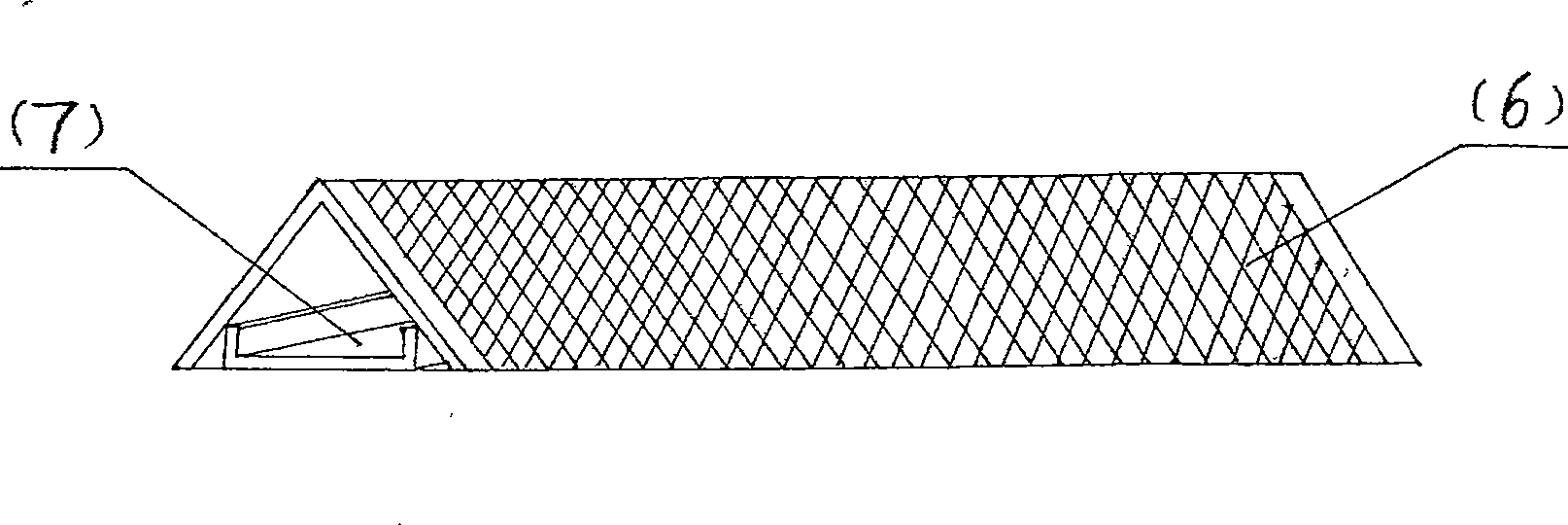

[0057] Example 1: Carbonization furnace

[0058] The carbonization furnace consists of a furnace body 1, a burner 4, an exhaust port 5, and a discharge port 2, such as figure 1 Shown. The furnace body of the carbonization furnace is 8mm thick double-layer steel plate, with asbestos silk as the middle insulation interlayer. The furnace body is a rectangular parallelepiped shape. The furnace body is semi-closed and has no cover on the top. The specific parameters of the special carbonization furnace for corncob pellet carbon are shown in the following table. At the bottom of the narrow side of the furnace body 1, there is a discharge port 2 for discharging and igniting the burner from the discharge port. The discharge port is square or semicircular. The size of the discharge port can be designed according to the volume of the furnace body. In principle, the material does not drip automatically after the furnace body is loaded. There is no sliding door outside the discharge port. Th...

Embodiment 2

[0061] Example 2 Production method of corncob granular charcoal

[0062] The method for producing corn cob granular charcoal using the carbonization furnace described in Example 1 includes the steps of selecting materials, processing materials, charging furnace carbonization, cooling and discharging, and metering and packaging.

[0063] Material selection: Naturally air-dry the corncobs of agricultural and sideline products to reduce the moisture content to below 20%.

[0064] Material processing: using any crushing method in the prior art to process and crush the above qualified corn cobs, and the diameter of the crushed corn cob particles is 2-10 mm. The crushed corn cob particles can be sieved through a sieve, and the corn cob particles that do not meet the requirements can be reprocessed.

[0065] Furnace carbonization: The processed corncob pellets are loaded into the furnace body, and the initial amount of material is added to cover the burner by 10-25 cm. Ignite the ignitor...

Embodiment 3

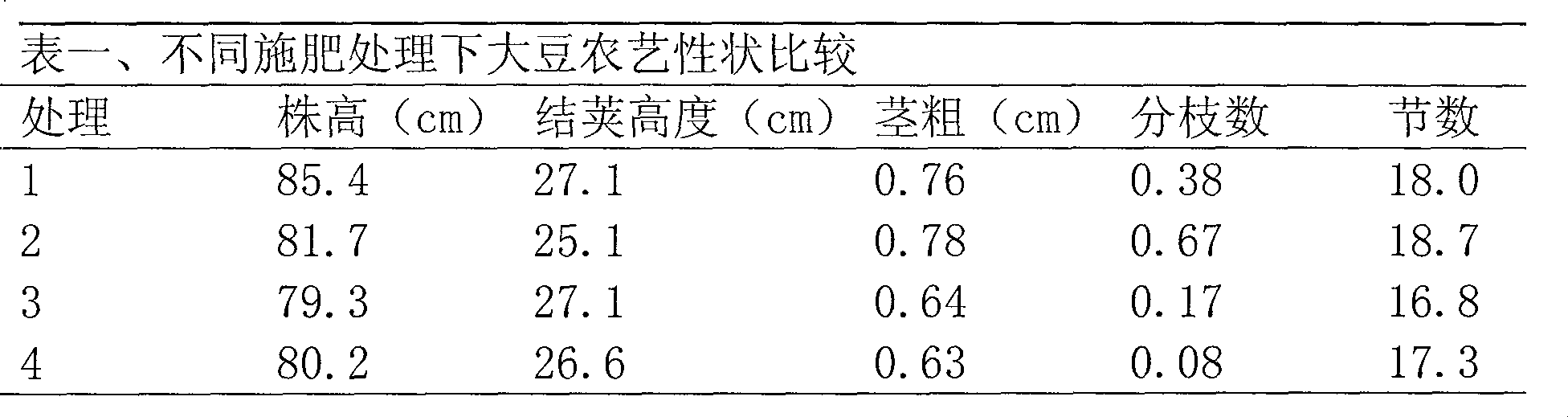

[0068] Example 3 Production process of carbon-based slow-release soybean special fertilizer

[0069] Combine 80 kg of urea (containing N46%), monoammonium phosphate (containing N11%, P 2 O 5 46%) 280 kg, corn cob granular carbon particles 300 kg, potassium sulfate (including K 2 O50%) 230 kg, zinc sulfate (containing 20% to 23% zinc) 10 kg, borax (containing 11% boron) 22 kg, molybdenum fertilizer (containing 10% molybdenum) 8 kg, binder 70 kg, mix with ZLC -300 mixer (common machinery in the fertilizer preparation process) and KP-300 organic fertilizer granulator (common machinery in the fertilizer preparation process) for pressure granulation, and other types of mixers and granulators can also be used for mixing Granulation. The binder is acid bentonite with pH 5.5-6.5. The particle size of the corncob granular carbon particles is preferably 80-100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com