Method for preparing IIB group semiconductor sulfide nano-material

A nanomaterial and semiconductor technology, which is applied in the synthesis field of preparing IIB group sulfide semiconductor nanomaterials, can solve the problems of high reaction temperature requirements, high cost, and difficult to control the morphology of toxic gas products, and achieves low cost, simple operation, Effects that are easy to build

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

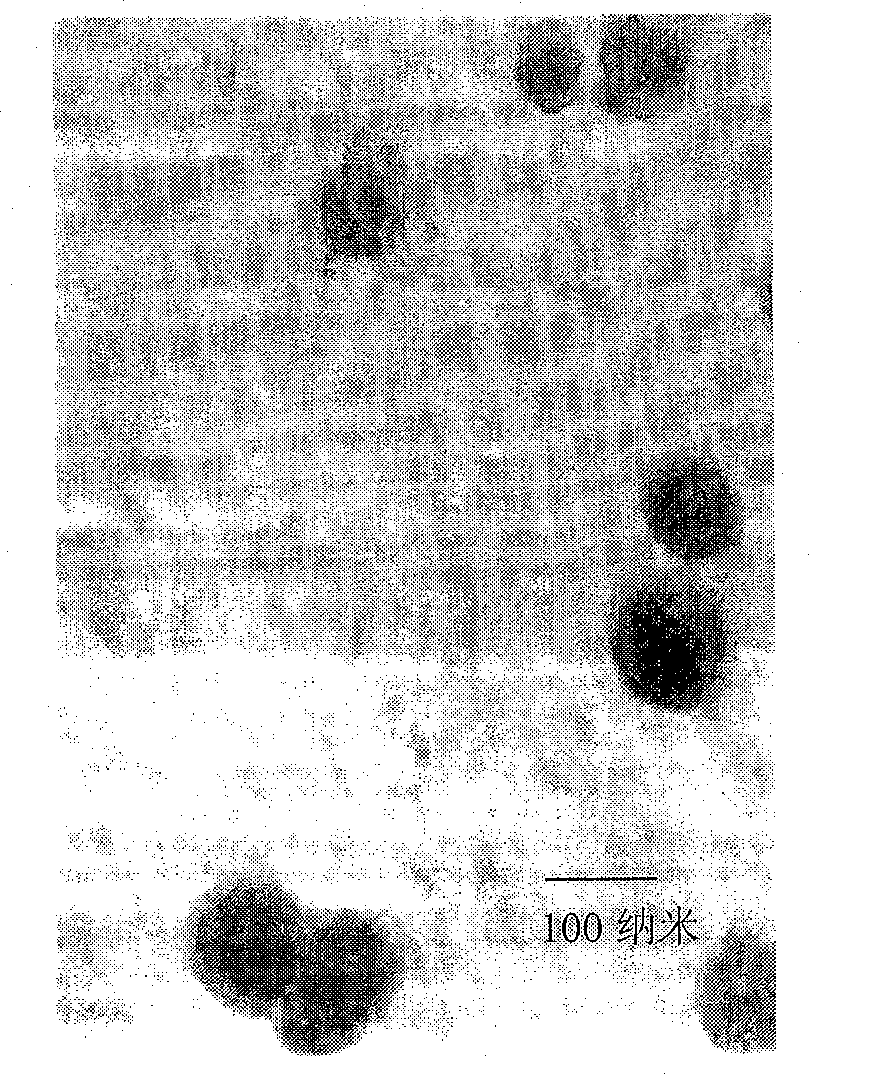

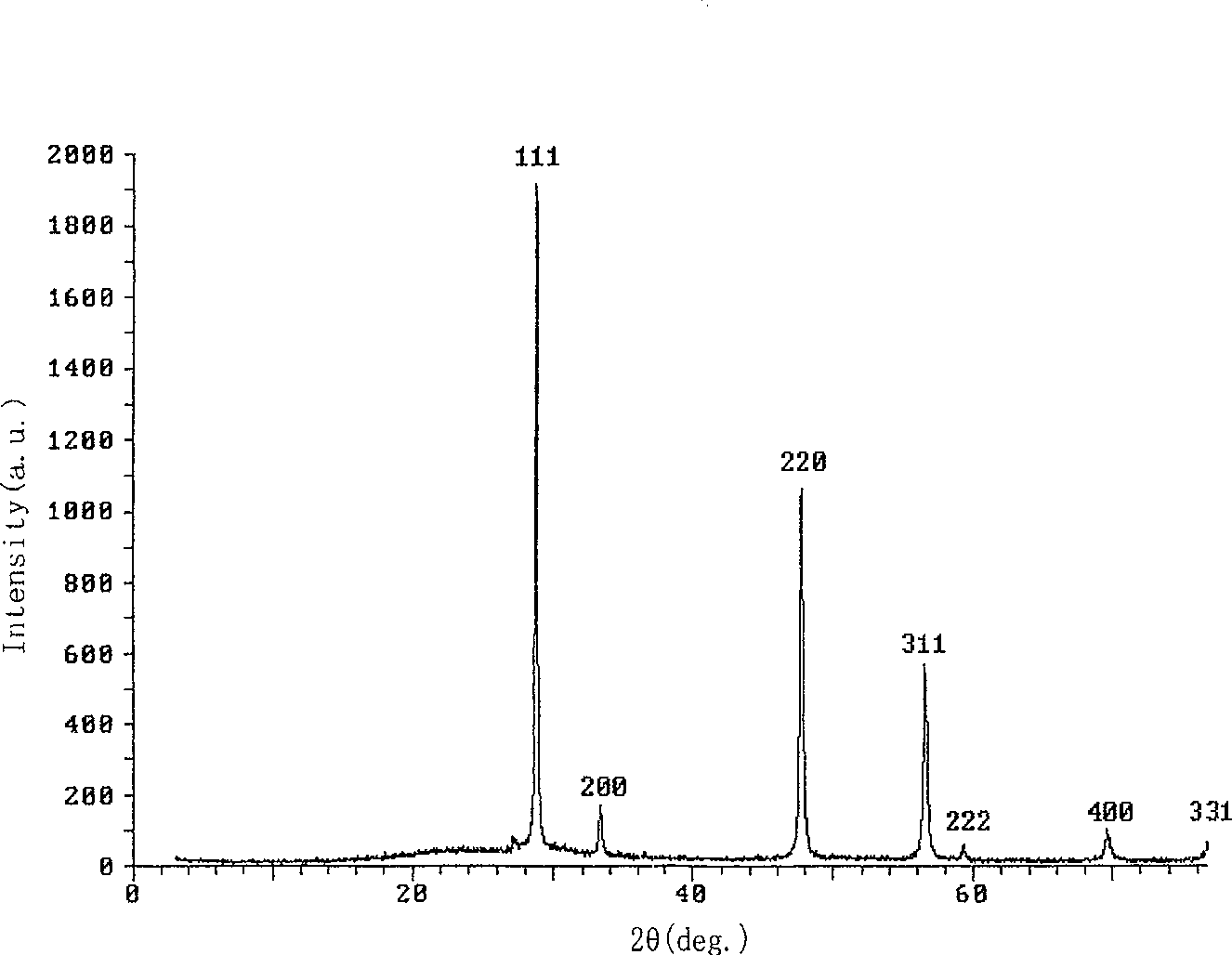

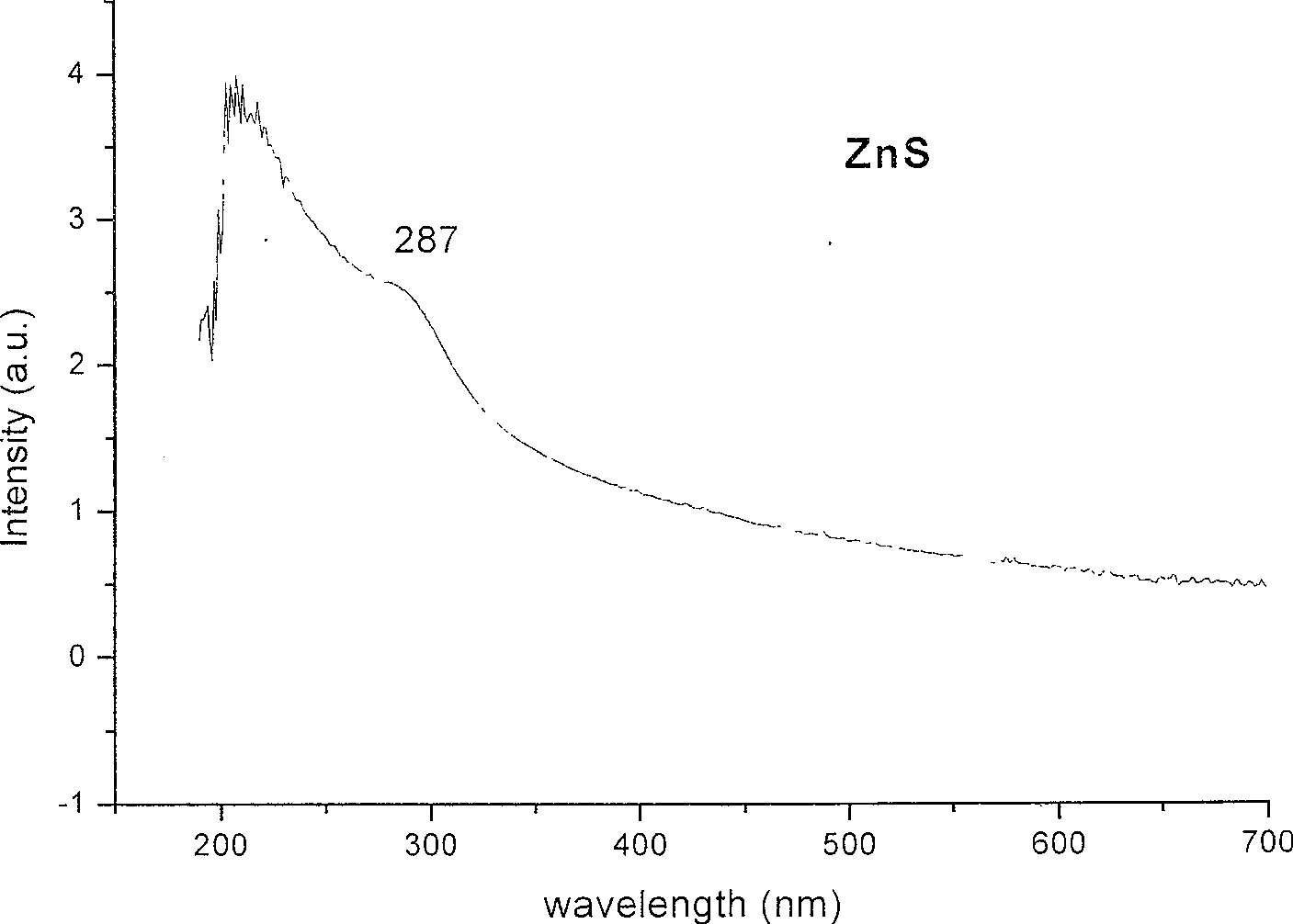

[0020] The first step, weigh 0.010mol zinc powder (analytical pure), sulfur source is 0.010mol Na 2 S (analytical pure). Na 2 S was dissolved in an appropriate amount of distilled water to form a solution.

[0021] In the second step, 0.010mol zinc powder and Na 2 The S solution was placed in a 45mL autoclave lined with polytetrafluoroethylene, and distilled water was added to it to 3 / 4 of the volume of the autoclave. N was then introduced into the reaction solution 2 After removing the dissolved oxygen in the solution, the autoclave was closed, placed in an oven, and heated at 140° C. for 12 hours. After the reaction was finished, the oven was closed, and the autoclave was naturally cooled (gradient temperature drop) to room temperature. Centrifuge at 200rpm with a centrifuge, and suck out the supernatant with a dropper.

[0022] Step 3: Take out the precipitate, wash with water, acetone, and absolute ethanol three times in sequence, and finally store the product in abs...

Embodiment 2

[0024] Replace 0.010mol zinc powder with 0.010mol cadmium powder, reaction temperature is 180 ℃, and sulfur source is 0.015mol thiourea Other conditions and steps are identical with embodiment 1, and the product that obtains is rod-shaped cadmium sulfide nanomaterial, and nanorod diameter is 75nm, about 2.3μm long. And the length and thickness of the rods are relatively uniform. CdS nanorods are cubic phase crystals, and their properties are basically similar to those of ZnS nanocrystals.

Embodiment 3

[0026] Replace 0.010mol zinc powder with 0.010mol mercury, the reaction temperature is 200°C, and the sulfur source is 0.020molK 2 S, the reaction time was 24 hours, other conditions and steps were exactly the same as in Example 1, and the product obtained was mercury sulfide particles with an average particle size of 30nm. The ultraviolet absorption peak of HgS nanoparticles has obvious "blue shift" compared with conventional materials, and the results of fluorescence spectrum analysis show that the product has photoluminescence properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com