Method of preparing sulfide nano material of lead with calixarene adjusting solvent thermal system

A technology of chalcogenides and nanomaterials, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of high reaction temperature requirements, high cost, and difficult to control the morphology of toxic gas products, and achieves low cost and operation. Simple, low-cost production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.001 mole of Pb(NO 3 ) 2 Solid and 0.01 g of calix[4]arene were placed in a 50 ml beaker, a small amount of toluene was added, and after stirring at 80°C for 1 hour, the mixture was transferred into a 40 ml polytetrafluoroethylene reactor, and then 0.001 mole of thiourea was added to the mixed solution. Add toluene to the reactor to 3 / 4 of the volume of the reactor, seal it, and react at 170°C for 24 hours. The reaction kettle was naturally cooled to room temperature. The obtained product was taken out, washed alternately with distilled water and absolute ethanol for 3-6 times, centrifuged, and vacuum-dried at 60° C. to obtain the desired product.

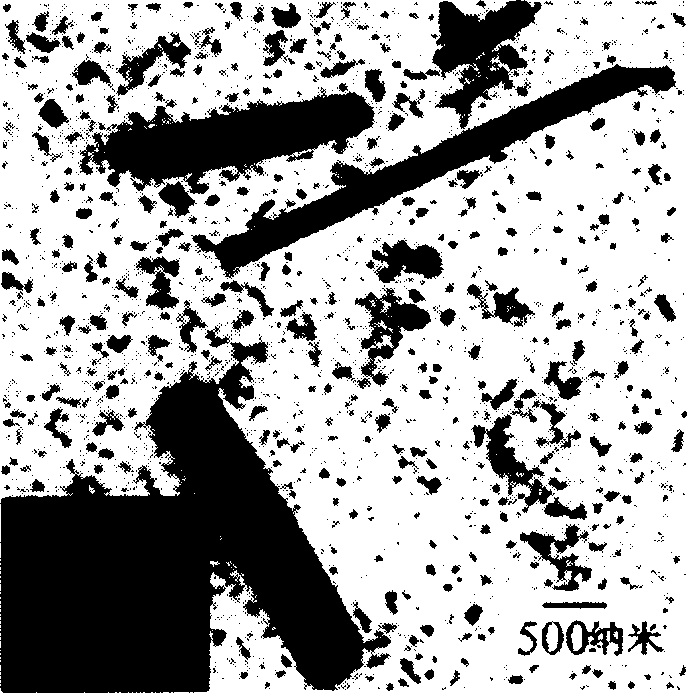

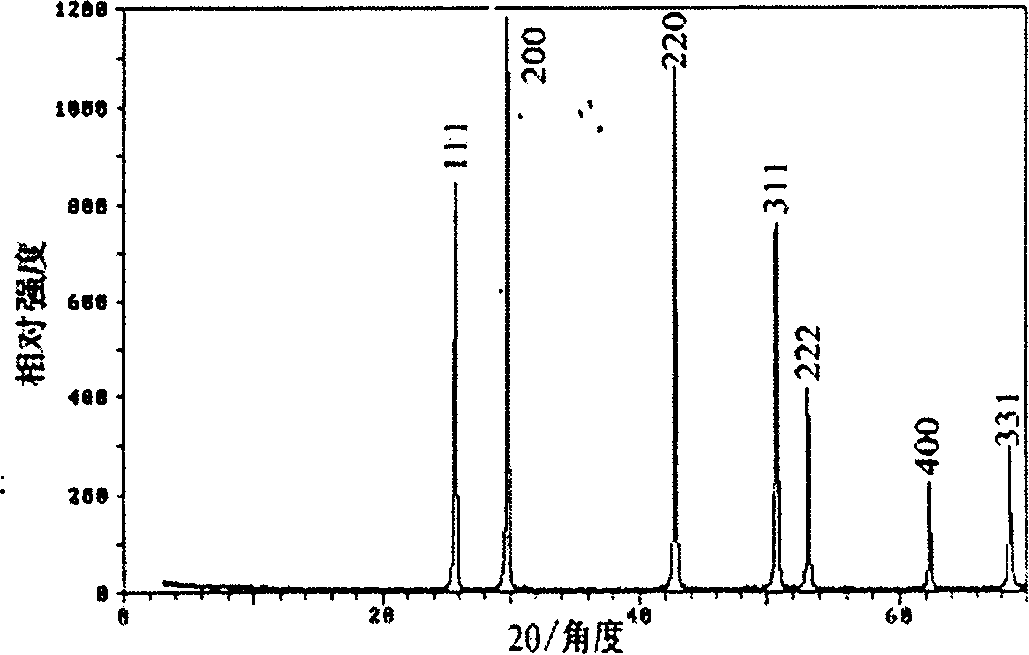

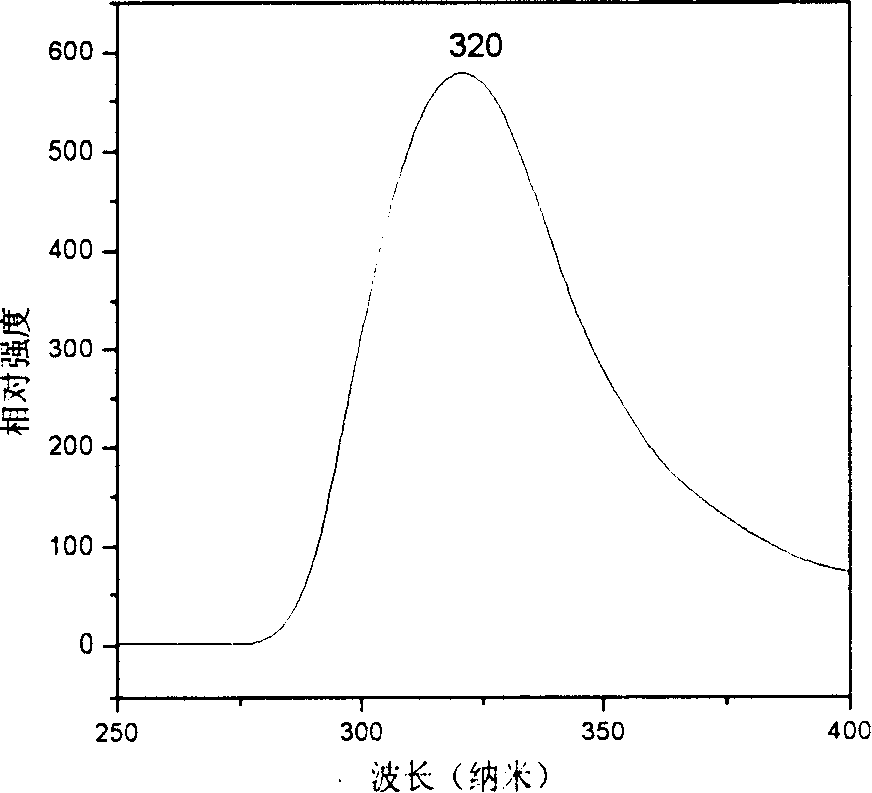

[0030] The morphology and structure of the product were characterized by transmission electron microscope (TEM) and X-ray powder diffractometer (XRD), as figure 1 The TEM shown shows that the product is a PbS quasi-nanorod with a diameter of 200 nm and a length of about 3.5 microns, as figure 2 The XRD results sh...

Embodiment 2

[0032] Weigh 0.001 mole of PbAc 2 Put the solid and 0.01 g of calix[4]arene into a 50 ml beaker, add a small amount of toluene, stir at 70 ° C for 1.5 hours, transfer the mixed solution into the reaction kettle, then add 0.001 mole of thiourea to the reaction kettle, and add toluene at the same time to 4 / 5 of the volume of the reactor, seal it, react at 150°C for 30 hours, cool the reactor to room temperature naturally, take out the obtained product, alternately wash with distilled water and absolute ethanol for 3-6 times, centrifuge and store at 70°C Dry under vacuum to obtain the desired product. The obtained product is a PbS quasi-nanorod with a diameter of about 200 nanometers and a length of about 3 microns, and the crystal system of the product is the same as that of Example 1. The product has high purity and good crystallinity. The optical properties are basically similar to Example 1.

Embodiment 3

[0034] Weigh 0.001 mole of Pb(NO 3 ) 2 Put the solid and 0.01 g of calix[4]arene into a 50 ml beaker, add a small amount of toluene, stir at 80°C for 1 hour, transfer the mixed solution into the reaction kettle, then add 0.001 mole of selenium powder to the reaction kettle, and add toluene at the same time to 3 / 4 of the volume of the reactor, sealed, reacted at 190°C for 20 hours, cooled the reactor to room temperature naturally, took out the obtained product, and cooled the reactor to room temperature naturally. The obtained product was taken out, washed alternately with distilled water and absolute ethanol for 3-6 times, centrifuged, and vacuum-dried at 80° C. to obtain the desired product. The obtained product is a PbS nanorod with a diameter of about 60 nanometers and a length of about 3 microns, and the crystal system of the product is the same as in Example 1. The product has high purity, good crystallinity and optical properties. The optical properties are basically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com