Process for preparing and extracting tert-butyl acetate

A technology of tert-butyl acetate and acetic acid, which is applied in the field of preparation and purification of tert-butyl acetate, can solve problems such as failure and difficulty in separation and purification of tert-butyl acetate, and achieve reduction of production costs, continuous esterification reaction and separation and purification, and overcome Difficult water separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

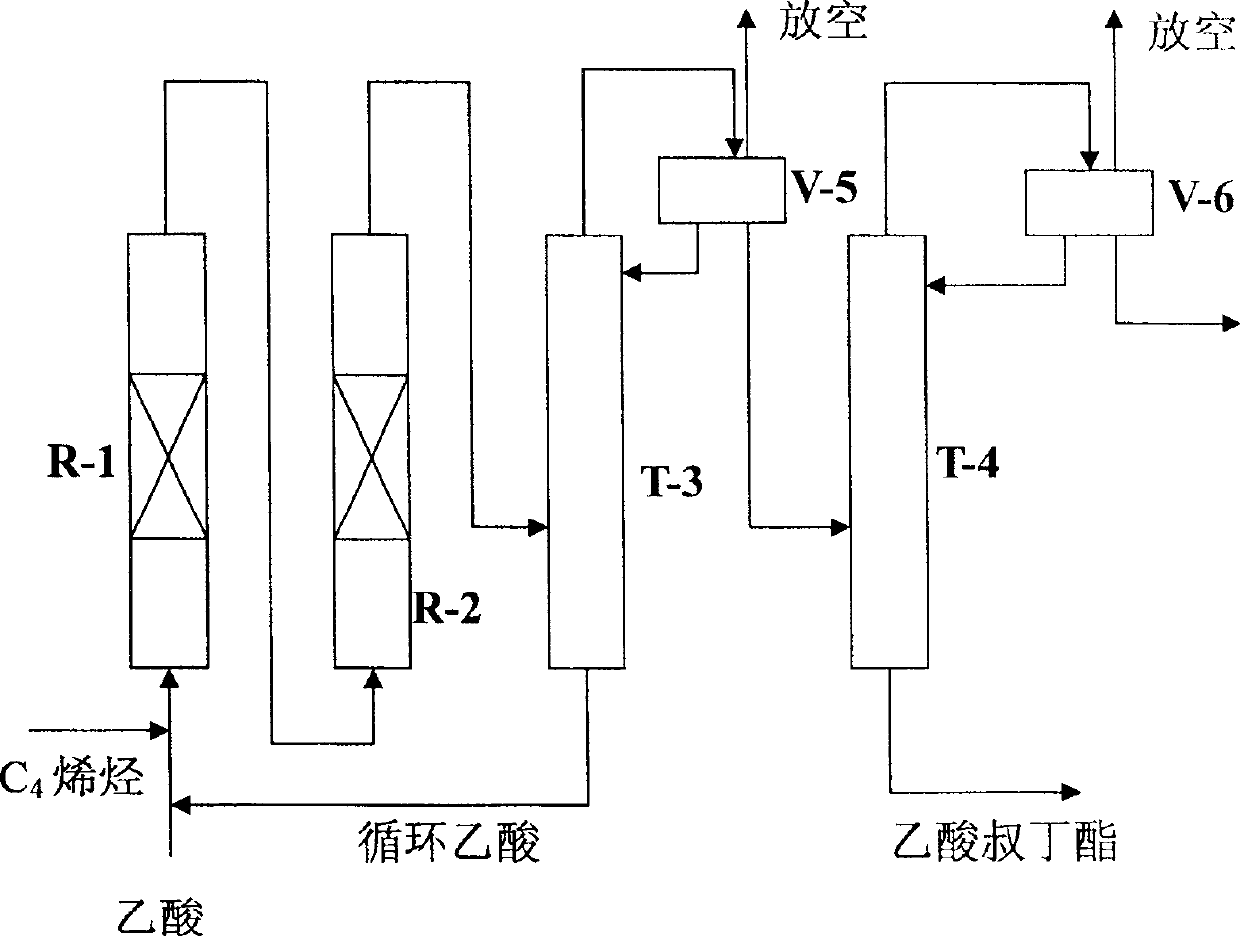

Method used

Image

Examples

Embodiment 1

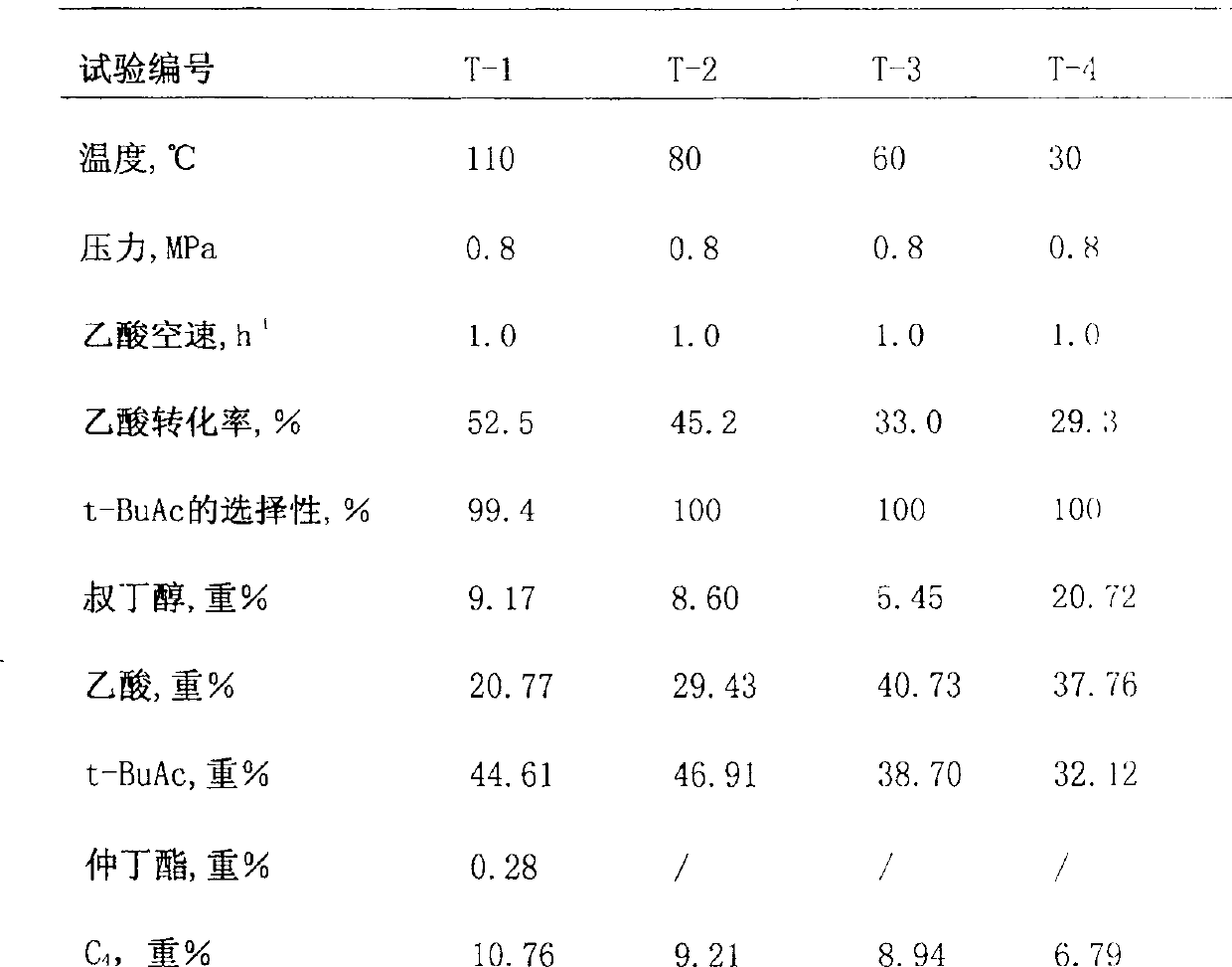

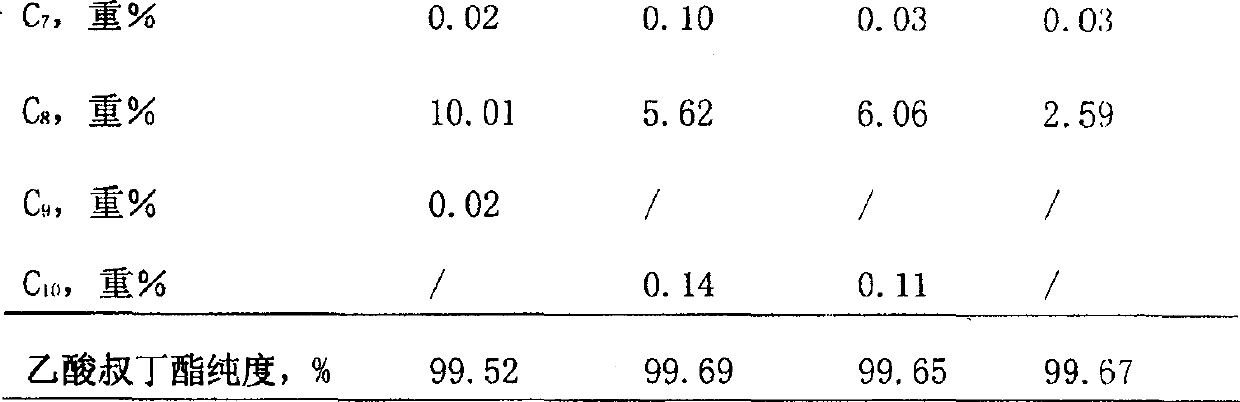

[0017] Acetic acid and C 4 The reaction is acid catalyzed and can be operated in batch or continuous mode. The inner diameter of the reaction tube is 16mm. The catalyst is a strong-acid ion-exchange resin. The loading amount of the catalyst is 30ml to 90ml. The acetic acid is metered in with an advection pump, and the temperature is controlled by a temperature control device. The raw materials used in experiments T-1, T-2, T-3, and T-4 were acetic acid and C 4 , acetic acid is fed into the esterification tower equipped with ion-exchange resin catalyst at a certain rate to maintain a stable C 4 Tail gas flow rate (60ml / min), pressure 0.8MPa, change reaction temperature, react for 6-7 hours and take samples for analysis. The crude ester is deacidified at 85-100°C, dehydrocarbonized at 70-85°C, dealcoholized at 78-90°C, and finally rectified at 90-100°C to obtain tert-butyl acetate product. The results are shown in Table 1.

[0018] Table 1, change the result of reaction temp...

Embodiment 2

[0022] The raw materials used in experiments T-5, T-6, T-8, T-10 and T-11 are acetic acid, water and C 4 , the raw materials used in experiment T-7 were acetic acid, alcohol and C 4 , experiment T-9 with acetic acid and C 4 Be raw material, keep reaction temperature be 65 ℃, change acetic acid space velocity and reaction pressure, other conditions are the same as embodiment 1. The crude ester is deacidified at 85-100°C, dehydrocarbonized at 70-85°C, dealcoholized at 78-90°C, and finally rectified at 90-100°C to obtain tert-butyl acetate product. The results are shown in Table 2.

[0023] Table 2, change the result of acetic acid space velocity and reaction pressure synthesis thick tert-butyl acetate

[0024]

[0025]

Embodiment 3

[0027] The tert-butyl acetate crude product (containing tert-butyl acetate 18.97%) that is obtained by the first esterification tower circulates into the second esterification tower, and supplemented C 4 Esterification occurs, controlling C 4 Exhaust gas flow 60ml / min. Keep the reaction temperature at 65°C, change the reaction pressure and the crude tert-butyl acetate injection space velocity to carry out experiments T-12, 13, 14, 15, and 16, and other conditions are the same as in Example 1, and react for 3 hours and take samples for analysis. The crude ester is deacidified at 85-100°C, dehydrocarbonized at 70-85°C, dealcoholized at 78-90°C, and finally rectified at 90-100°C to obtain tert-butyl acetate product. The results are shown in Table 3.

[0028] Table 3, change reaction pressure and the result of tert-butyl acetate crude product injection space velocity synthetic tert-butyl acetate cyclic reaction

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com