Method for preparing carbon nano-tube loading ruthenium oxide hydration composite material

A technology of carbon nanotubes and composite materials, which is applied in the direction of electrolytic organic material coating, fixed capacitor parts, fixed capacitor electrodes, etc., can solve the problems of difficult industrialization, complicated process, difficult control, etc., and achieve excellent capacitance performance, preparation Simple conditions and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

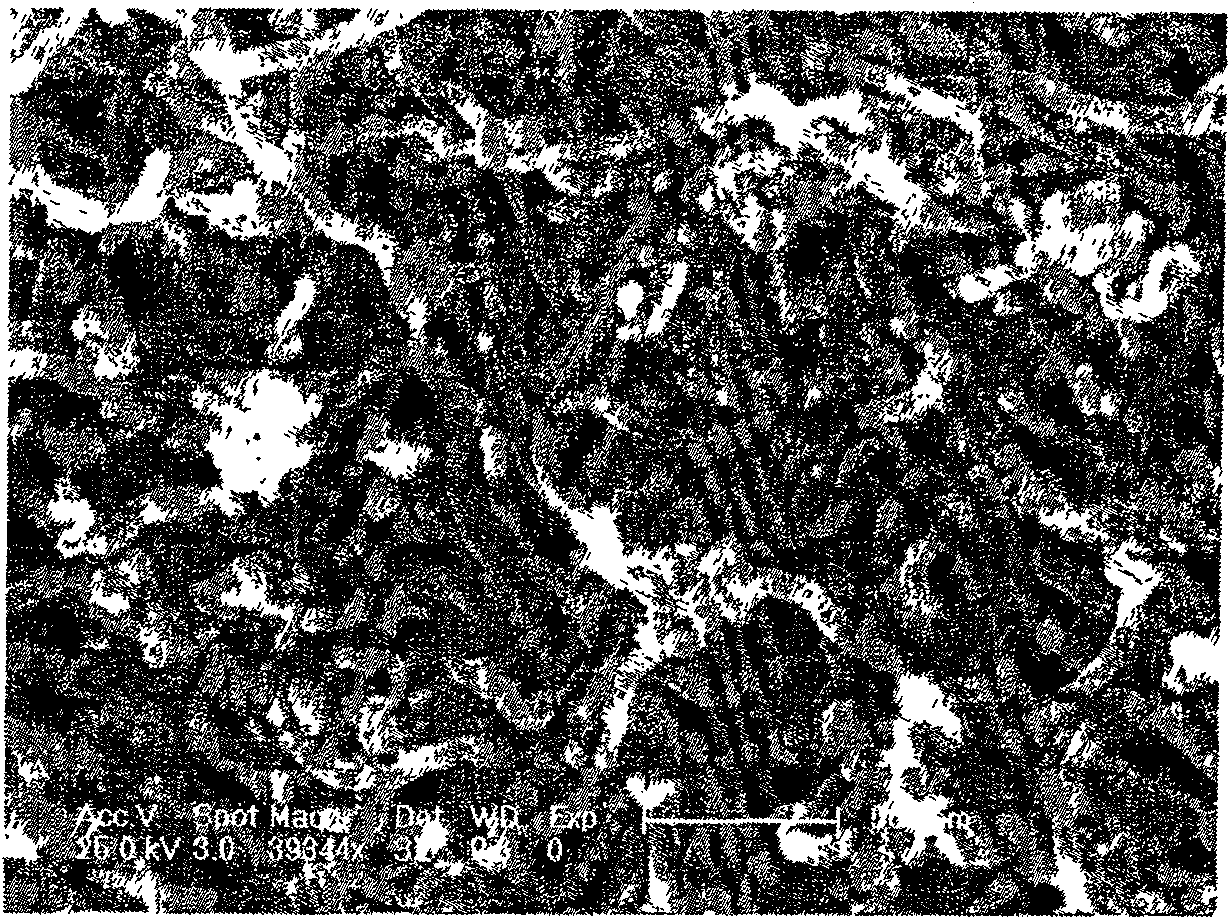

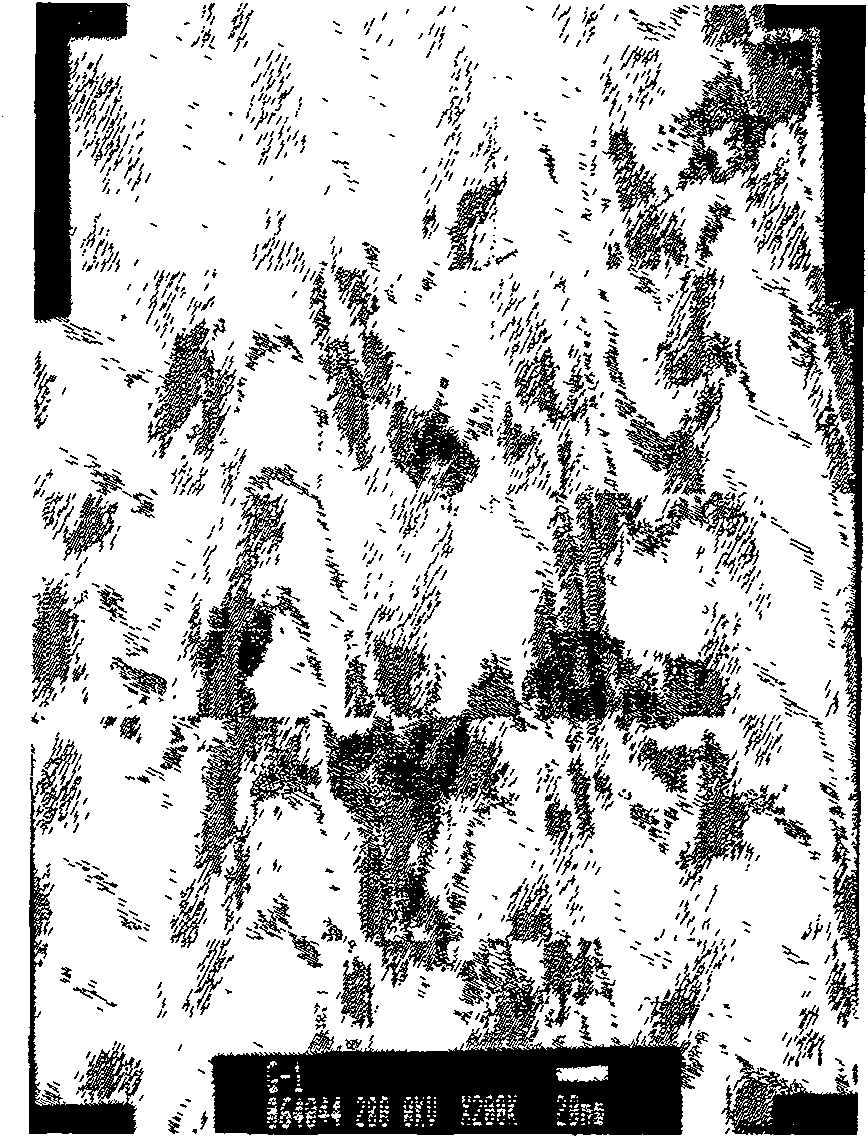

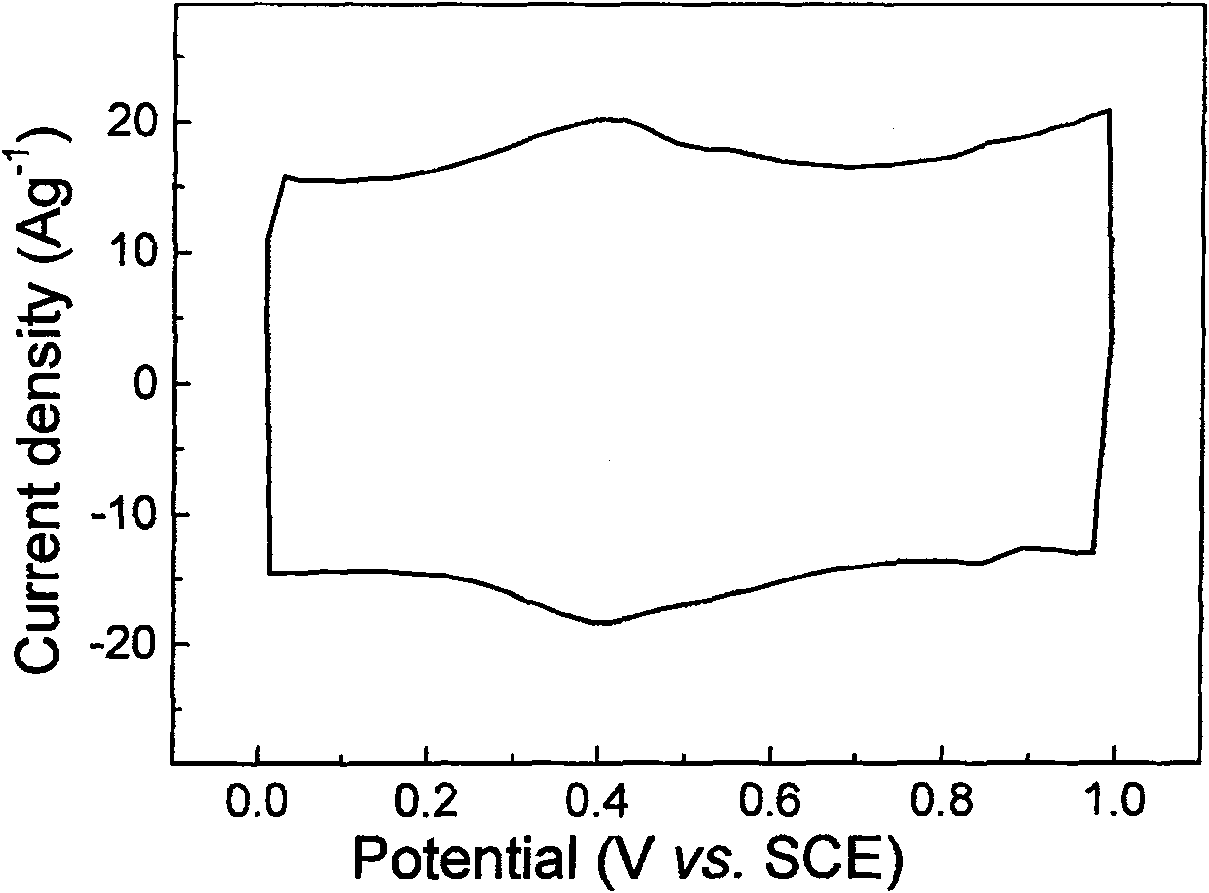

[0026] The process steps of the method for preparing the carbon nanotube / hydrated ruthenium oxide nanopowder composite material in this embodiment are as follows:

[0027] Implementation one:

[0028] 1), preparing electrodeposition solution, ruthenium trichloride 2.092g / L, sodium nitrate 42.5g / L, polyvinyl alcohol 4.0g / L are mixed into 250ml aqueous solution;

[0029] 2), disperse 4.0g / L of multi-walled carbon nanotubes in the main body solution;

[0030] 3) Take 20×20mm copper sheet as cathode and 20×20mm platinum sheet as anode; the current density used is 0.05A / cm 2 ;

[0031] 4), control the electrodeposition time, adjust the pH value in the solution to about 8, stir for 5 hours, and stabilize the precipitation;

[0032] 5) Put the electrodeposited carbon nanotube / ruthenium hydroxide precipitate into an oven for heat treatment at 150° C. for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com