Prefabricated spiral phenolic aldehyde insulation tube and its production method

A technology of phenolic heat preservation and spiral pipe, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor heat preservation performance and easy deformation, and achieve the effect of good mechanical strength, good heat preservation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

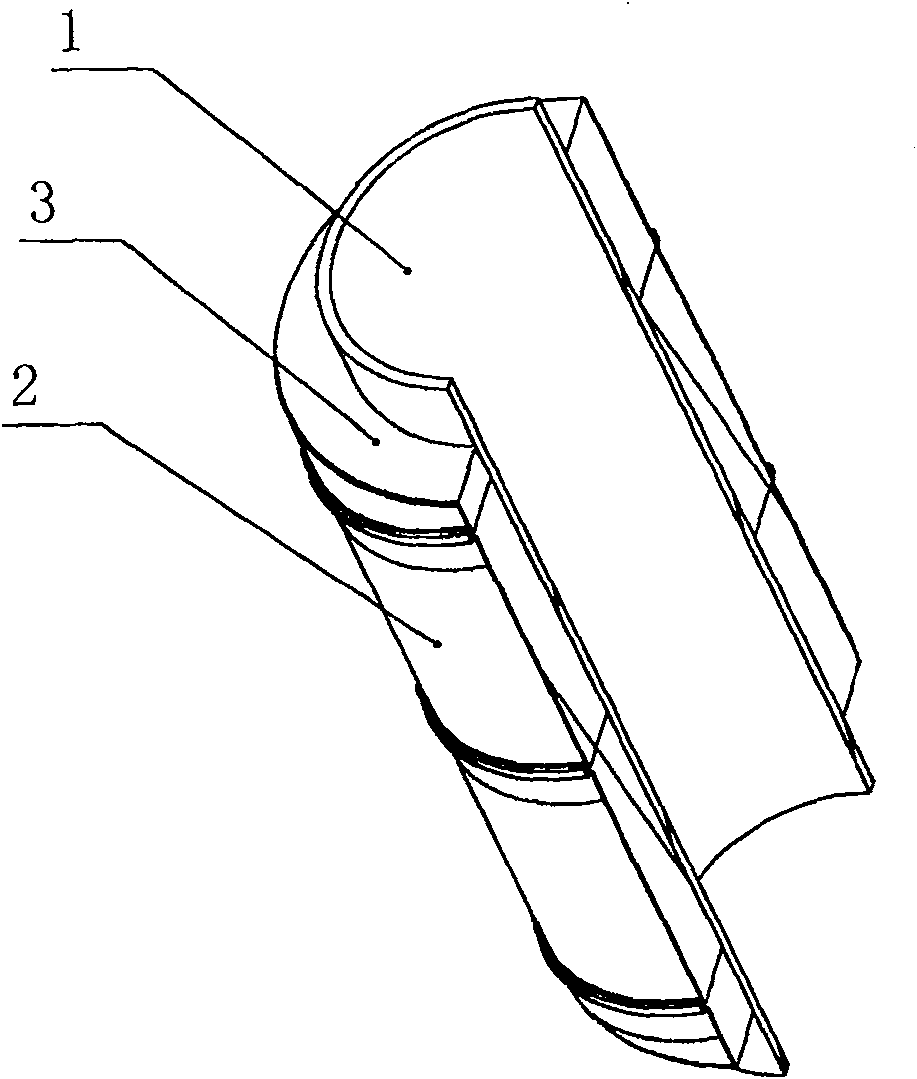

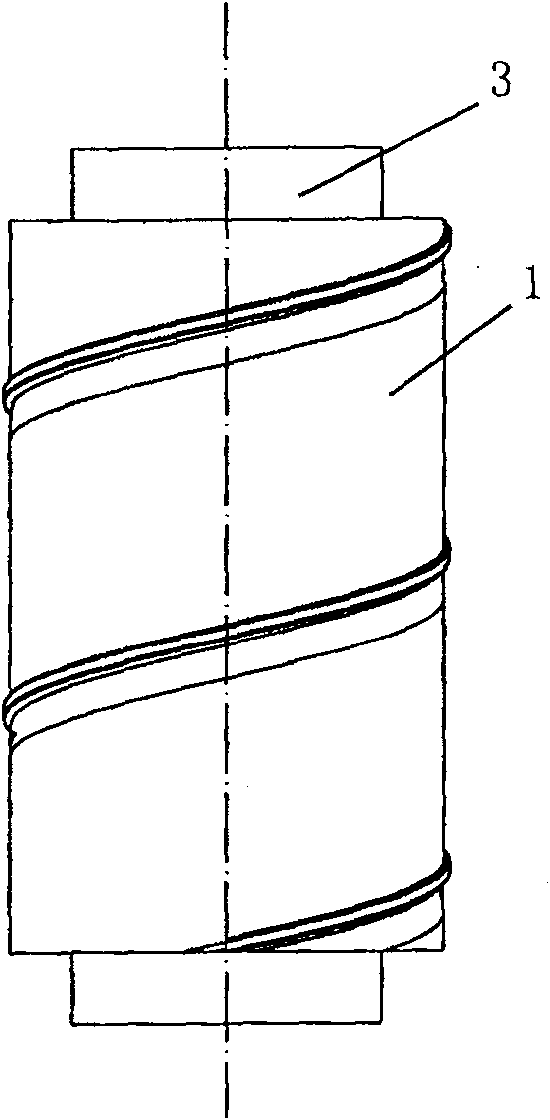

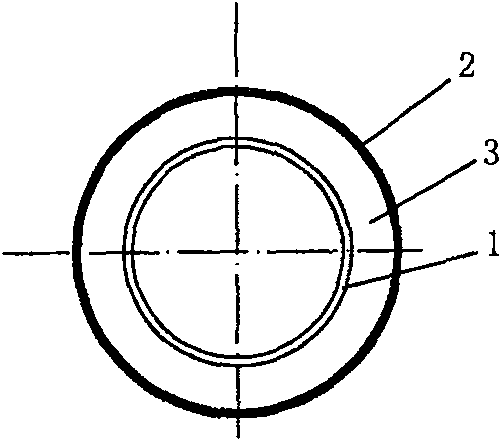

[0020] Embodiment 1: see Figure 1~5 , The prefabricated spiral phenolic insulation pipe is a three-layer composite pipe, which is provided with an inner pipe 1, an outer pipe 2 and a middle interlayer 3. The inner pipe 1 is a galvanized pipe or a seamless steel pipe. The outer pipe 2 is a galvanized iron strip spiral pipe, and the galvanized iron strip spiral pipe is formed by spiral processing of the galvanized iron strip. The interlayer 3 between the inner pipe 1 and the outer pipe 2 is an insulation layer, and the insulation layer is a phenolic foam insulation layer formed by direct foaming of phenolic resin. The outer diameter of the inner pipe is 22mm, the thickness of the interlayer insulation layer is 20mm, and the thickness of the outer pipe wall is 0.4mm. The phenolic foam of the phenolic foam insulation layer is composed of phenolic resin, flame retardant, modifier, surfactant, curing agent and foaming agent, flame retardant, modifier, surfactant, curing agent and...

Embodiment 2

[0021] Embodiment 2: Similar to Embodiment 1, the inner pipe of the prefabricated spiral phenolic insulation pipe is a PVC pipe or a PU pipe, and the outer pipe is a spiral pipe with a color steel strip, and the spiral pipe with a color steel strip is formed by spiral processing of a color steel strip. The outer diameter of the inner pipe is 100mm, the thickness of the interlayer insulation layer is 100mm, and the thickness of the outer pipe wall is 1.0mm. The phenolic foam of the phenolic foam insulation layer is composed of phenolic resin, flame retardant, modifier, surfactant, curing agent and foaming agent, flame retardant, modifier, surfactant, curing agent and foaming agent respectively Using antimony trioxide, ethylene glycol, Tween 60, hydrochloric acid and petroleum ether, the content of phenolic resin, flame retardant, modifier, surfactant, curing agent and foaming agent is 100% of phenolic resin by mass ratio, Antimony trioxide 2, ethylene glycol 6.5, Tween 60 2.5, ...

Embodiment 3

[0022] Embodiment 3: Similar to Embodiment 1, the inner pipe of the prefabricated spiral phenolic insulation pipe is a stainless steel pipe or an aluminum alloy pipe. The outer tube is an aluminum strip spiral tube, and the aluminum strip spiral tube is formed by spiral processing of the aluminum strip. The outer diameter of the inner pipe is 300mm, the thickness of the interlayer insulation layer is 135mm, and the thickness of the outer pipe wall is 0.6mm. The phenolic foam of the phenolic foam insulation layer is composed of phenolic resin, flame retardant, modifier, surfactant, curing agent and foaming agent, flame retardant, modifier, surfactant, curing agent and foaming agent Using boric acid, glycerin, dimethyl cyclosiloxane, methanesulfonic acid and n-pentane respectively, the content of phenolic resin, flame retardant, modifier, surfactant, curing agent and foaming agent is phenolic Resin 100, boric acid 3.5, glycerin 1, dimethylcyclosiloxane 1, methanesulfonic acid 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com