Preparation method of glass transition temperature halogenless fire retardant glass cloth laminated board

A technology with transition temperature and high vitrification, applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve problems such as poor heat resistance, low moisture resistance, and not very deep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

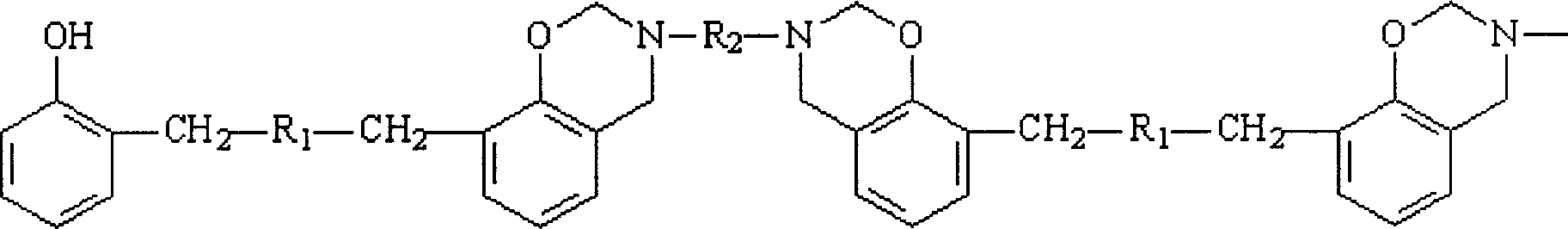

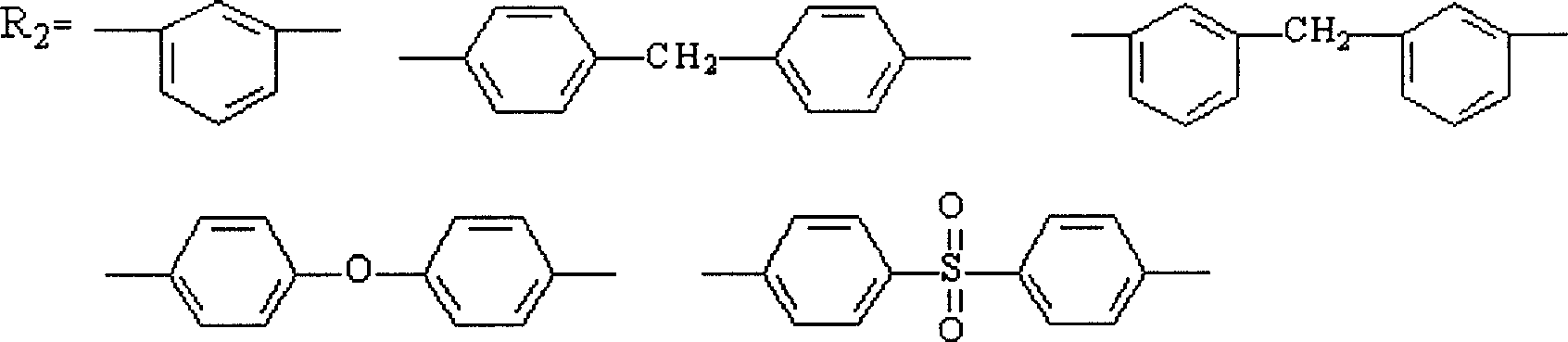

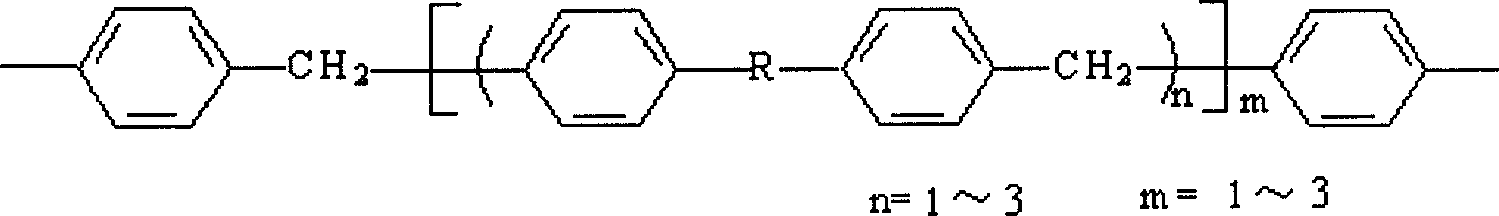

[0085] 20 parts of benzoxazine resin containing aralkyl structure (in the structural formula (1)) solution (in terms of resin solid weight parts, the same below), phosphorus-containing epoxy resin [in the structural formula of phosphorus-containing epoxy resin (3)] 5 parts (in terms of resin solid weight parts, the same hereinafter), phosphorus-containing epoxy resin ((7) n=1-10 in the phosphorus-containing epoxy resin structural formula) 5 parts (in terms of resin solid weight parts, hereinafter the same), 0.02 parts of 2-methylimidazole, 50 parts of butanone, 15 parts of toluene, and 15 parts of inorganic flame retardant silicon dioxide.

Embodiment 2

[0087] 90 parts of benzoxazine resin (in the structural formula (1)) solution containing aralkyl structure, 80 parts of phosphorus-containing epoxy resin ((7), n=1-10 in the structural formula of phosphorus-containing epoxy resin), 4, 10 parts of 4' diaminodiphenyl sulfone, 0.05 part of N, N dimethylbenzylamine, 40 parts of butanone, 25 parts of ethylene glycol dimethyl ether, organic phosphorus-containing flame retardant (organic phosphorus-containing flame retardant in the structural formula (b)) 5 parts, 10.5 parts of inorganic flame retardant aluminum hydroxide.

Embodiment 3

[0089] 90 parts of benzoxazine resin (in structural formula (2)) solution containing aralkyl structure, 50 parts of bisphenol A diglycidyl ether epoxy resin, epoxy curing agent (in the epoxy curing agent structural formula containing P structure (b)) 15 parts, 25 parts of phosphorus-containing epoxy resin ((3) in the structure formula of phosphorus-containing epoxy resin), 3.5 parts of 4,4' diaminodiphenylmethane, 0.04 parts of 2-ethyl-4-methylimidazole 20 parts, 20 parts of dimethylformamide, 35 parts of butanone, 3 parts of organic phosphorus-containing flame retardant ((d) in the structural formula of organic phosphorus-containing flame retardant), 20 parts of inorganic flame retardant magnesium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com