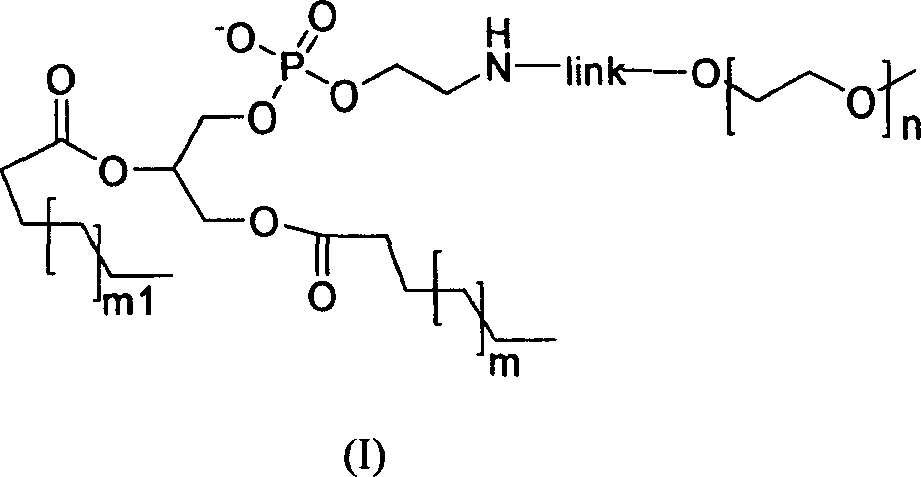

Polyethylene glycol-phosphatidyl ethanolamine polymer or medicinal acid addition salt and application thereof in pharmacy

A technology of phosphatidylethanolamine and polyethylene glycol, which is applied in the direction of medical preparations, antipyretics, antitumor drugs, etc. of non-active ingredients, can solve the problems of high price, limited use, long residence time, etc., and achieve product The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

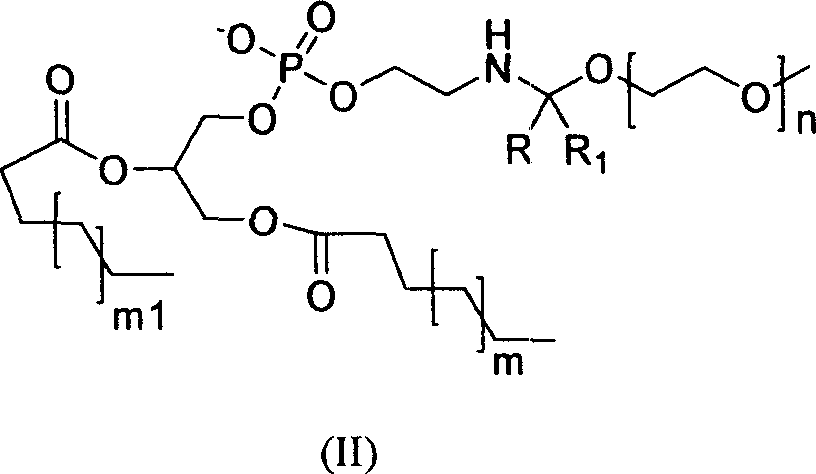

[0079] General method for preparing polyethylene glycol-phosphatidylethanolamine polymer general formula (II)

[0080] In a 1000ml three-necked bottle, add MPEG-2000 (20g; 0.01mol), distearoylphosphatidylethanolamine (0.01mol) and 500ml of chloroform, then add paraformaldehyde (3g, 0.1mol), stir and heat to reflux , slowly drop into concentrated hydrochloric acid 10ml, continue the reaction, TLC monitors the reaction process, the developer is 2-butanone / acetic acid / water=40 / 25 / 5, v / v / v, iodine color development, distearoyl phospholipid The Rf value of acyl ethanolamine was 0.68, and after 10 hours, distearoylphosphatidylethanolamine had mostly reacted completely, and the reaction solution was evaporated to dryness, and the residue was dissolved in 10ml of dichloromethane, and the shaving column chromatography was carried out, and the eluent was Dichloromethane and Methanol. The product fractions were combined and concentrated to obtain 11 g of colorless waxy methoxypolyethyle...

Embodiment 2

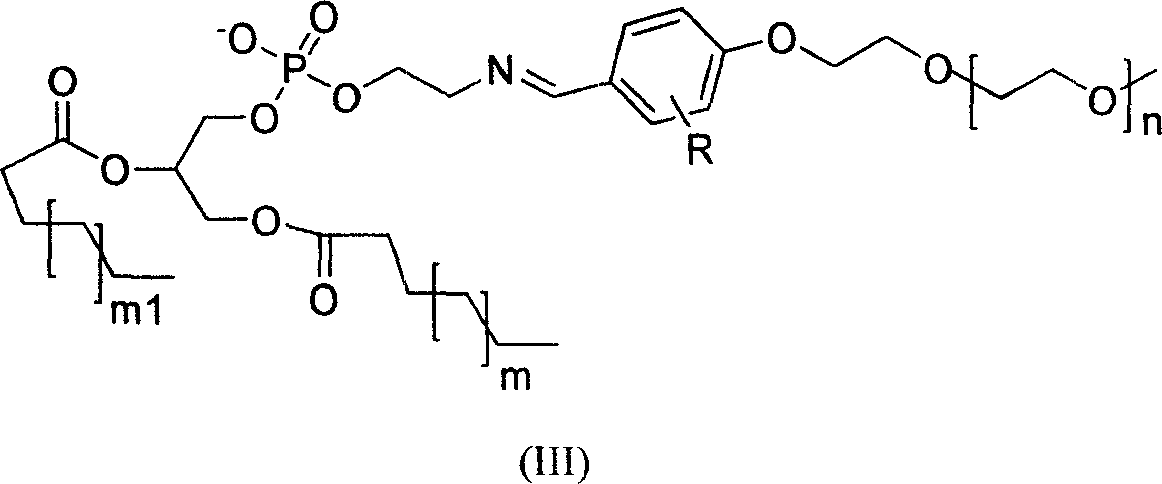

[0082] General method for preparing polyethylene glycol-phosphatidylethanolamine polymer general formula (III)

[0083] In a 1000ml three-neck flask, add cephalin (0.01mol), p-hydroxybenzaldehyde (1.22g, 0.01mol) and 300ml of anhydrous toluene, reflux with water until the evaporated toluene is clear, monitor the reaction progress by TLC, and set aside.

[0084] In a 500ml three-necked flask, add MPEG-1900 (19g; 0.01mol) and 300ml of anhydrous chloroform, cool with an ice-salt bath, slowly add 10ml of triethylamine and 3ml of trifluoromethanesulfonic anhydride, protect with inert gas, and stir overnight . The next day, slowly drop the reaction solution into the above reaction solution, gradually increase the temperature and evaporate the chloroform, react at 110°C for 16 hours, evaporate the reaction solution to dryness, dissolve the residue with 10ml of dichloromethane, perform column chromatography, wash The dehydration is dichloromethane and methanol. The product fractions...

Embodiment 3

[0086] The preparation general method of polyethylene glycol-phosphatidylethanolamine polymer general formula (IV)

[0087] method one:

[0088] In a 500ml three-necked flask, add MPEG-1500 (15g; 0.01mol) and 300ml of anhydrous benzene, under stirring, slowly drop into oxalic anhydride (1.4g, 0.02mol), continue to reflux for 4 hours, cool to room temperature, Add 10ml of freshly steamed thionyl chloride, continue the reflux reaction for 4 hours, gradually increase the temperature and evaporate to dryness, add anhydrous benzoic acid 3 times, dissolve in 300ml of anhydrous benzene and set aside.

[0089] In a 1000ml three-neck bottle, add distearoylphosphatidylethanolamine or cephalin (0.01mol), 10ml of triethylamine and 300ml of anhydrous benzene, under stirring, slowly add the above solution dropwise in an ice-salt bath, and dropwise , continue the reflux reaction for 6 hours, evaporate the reaction solution to dryness, dissolve the residue with 10ml of dichloromethane, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com