Yttria/titanium dioxide nano composite material and preparation process thereof

A nanocomposite material, titanium dioxide technology, applied in the field of yttrium oxide/titanium dioxide nanocomposite materials and its preparation, can solve the problems of narrow photoresponse range of semiconductors, high recombination probability of photogenerated electrons/hole pairs, and easy deactivation of conduction band electrons , to achieve the effect of expanding the photoresponse range, improving the charge separation effect, and requiring less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

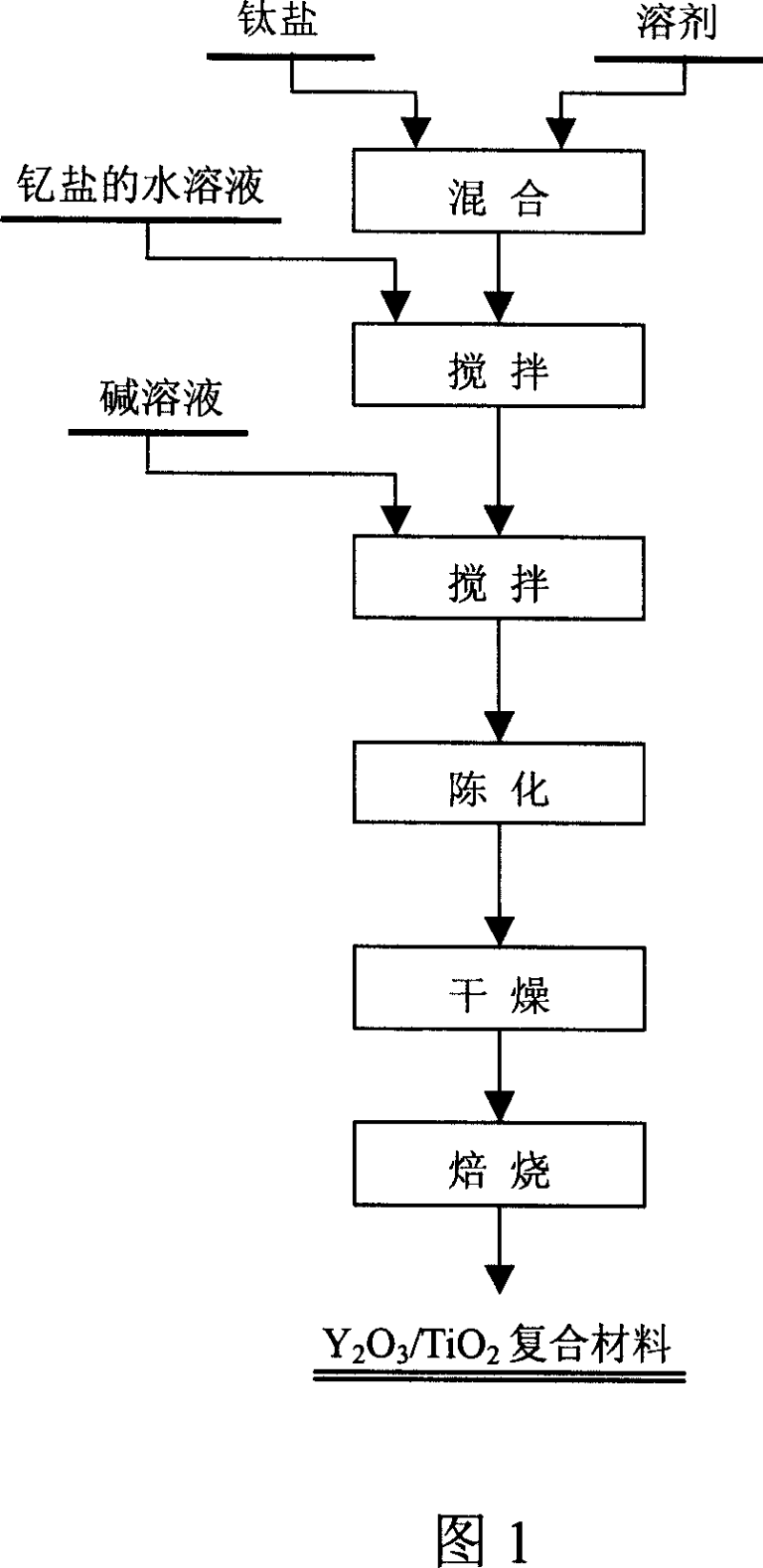

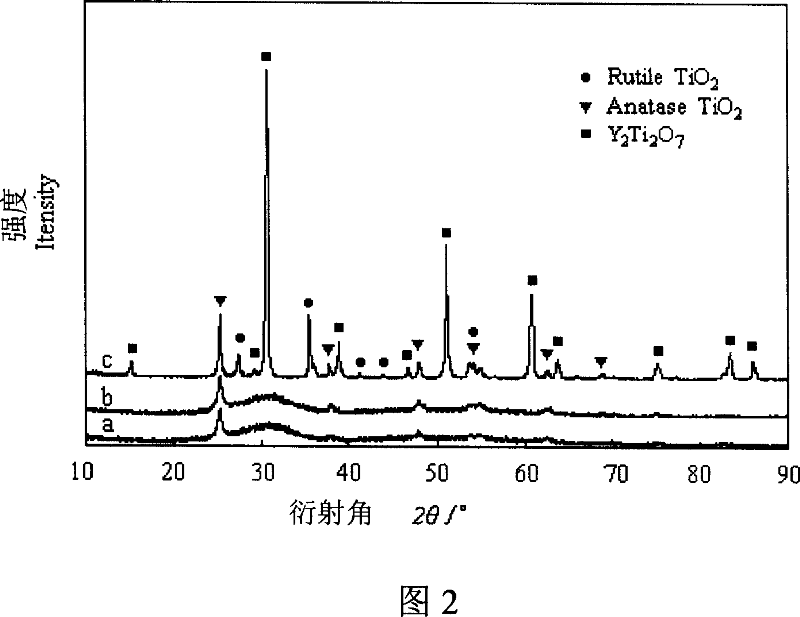

[0023] Referring to Fig. 1, it shows a schematic diagram of the process flow for preparing yttrium oxide / titania nanocomposite material. Take 10ml of butyl titanate (analytical pure) and 10ml of absolute ethanol and mix them with ultrasonic waves for 10min. The mixed solution was stirred with a heat-collecting constant temperature magnetic stirrer, and 3.617gY (NO 3 ) 3 ·6H 2 O, and the solution was added dropwise to the alcohol solution of butyl titanate, and the initial pH value of the reaction was controlled to be 9.5 with ammonia water. After stirring for two hours, the resulting sol was aged at room temperature for 24 h. Then the aged xerogel was filtered and washed twice with deionized water and absolute ethanol in a circulating water vacuum pump, and dried at 100°C in an electric heating constant temperature blast drying oven to obtain Y 2 o 3 / TiO 2 Nanocomposite precursors. Calcined at 600°C, 700°C, and 800°C for 4 hours in a box-shaped resistance furnace to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com