Pollution free organic fertilizer produced by aginomoto waste liquid and preparation method thereof

The technology of organic fertilizer and monosodium glutamate waste liquid is applied in the direction of organic fertilizer, inorganic fertilizer, fertilizer made of biological waste, etc., which can solve the problems of difficult formula adjustment, high packaging cost and high production cost, and achieves strong market competitiveness of products, The effect of improving soil physicochemical properties and soil physicochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

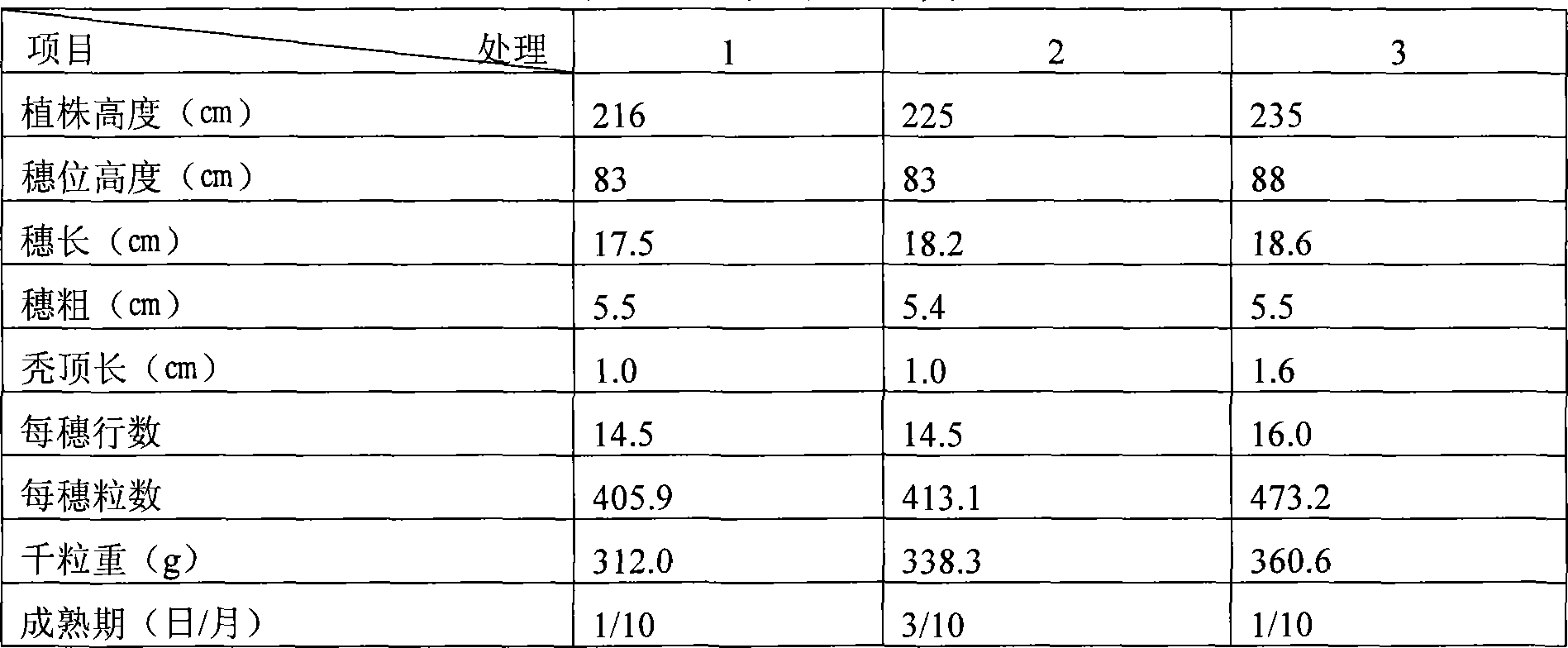

Image

Examples

Embodiment 1

[0080] A pollution-free organic fertilizer produced by using monosodium glutamate waste liquid, the components are as follows, all in parts by weight;

[0081] 50 parts of monosodium glutamate waste liquid, 20 parts of acid analysis lignin, 10 parts of weathered coal, 8 parts of monoammonium phosphate, 5 parts of potassium chloride, 5 parts of trace elements (iron, zinc, molybdenum, boron), 2 parts of curing agent, of which , the curing agent is a combination of water-soluble resin BLT167-65 and triglycidyl isocyanurate (TGIC) in a mass ratio of 1:0.3, and the trace elements are iron, zinc, molybdenum and boron in a mass ratio of 1:0.7:0.5:0.3: The combination.

[0082] The preparation method is as follows;

[0083] 50 parts of monosodium glutamate waste liquid (solid content 50%), 20 parts of acid-analyzed lignin, 10 parts of weathered coal (more than 50% of humic acid content), 8 parts of monoammonium phosphate, 5 parts of potassium chloride, trace elements (iron , zinc, m...

Embodiment 2

[0085] An organic fertilizer has the following components, all in parts by weight:

[0086] 35 parts of monosodium glutamate waste liquid (solid matter 50%), 25 parts of acid-analyzed lignin, 15 parts of weathered coal (more than 50% of humic acid content), 10 parts of monoammonium phosphate, 7 parts of potassium chloride, trace elements (iron, 4 parts of zinc, molybdenum, boron), 4 parts of curing agent, wherein the curing agent is a combination of water-soluble resin BLT167-65 and triglycidyl isocyanurate (TGIC) with a mass ratio of 1:0.5, and the trace elements are iron, zinc, The combination of molybdenum and boron mass ratio 1:0.5:0.8:0.2.

[0087] Preparation:

[0088] The above-mentioned components are added into the stirring tank in sequence by weight, stirred by a vertical mixer to a slurry-like uniform body while feeding, and then placed at room temperature to solidify for 4 days, so that the water content of the material is about 15%. The solidified material is gr...

Embodiment 3

[0090] An organic fertilizer has the following components, all in parts by weight:

[0091] 40 parts of monosodium glutamate waste liquid (solid matter 50%), 15 parts of acid-analyzed lignin, 5 parts of weathered coal (more than 50% of humic acid content), 15 parts of monoammonium phosphate, 10 parts of potassium chloride, trace elements (iron, Zinc, molybdenum, boron) 7 parts, curing agent 8 parts, above-mentioned curing agent is the combination of water-soluble resin BLT167-65 and triglycidyl isocyanurate (TGIC) mass ratio 1: 0.8, and above-mentioned trace element is iron, zinc , molybdenum, boron mass ratio 1:1:0.4:0.5: combination.

[0092] Preparation:

[0093] The above-mentioned components are added into the mixing tank in sequence by weight, stirred by a vertical mixer to a slurry-like homogeneous body, and then placed at room temperature for 2.5 days to solidify, so that the water content of the material is about 30%. The solidified material is granulated from the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com