Process of preparing magnetic drum for high precision magnetic coder

A magnetic encoder, high-precision technology, applied in the preparation of magnetic drums for high-precision magnetic encoders, and the field of magnetic rotary encoders, can solve the problems of low precision of magnetic drums, achieve no surface defects, easy industrialized mass production, sinusoidal waveforms uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1. Aluminum drum cleaning

[0018] The diameter of the aluminum drum is 40 mm, and it is ultrasonically cleaned with acetone, deionized water, and absolute ethanol for 10 to 15 minutes in order to remove oil stains and physical adsorption on the surface.

[0019] 2. Grinding and polishing the surface of the aluminum drum until the surface roughness Ra≤100nm.

[0020] 3. Electroless Co-P magnetic recording film: the main salt cobalt sulfate (CoSO 4 ·7H2O) 20g / L, reducing agent sodium hypophosphite (NaH2PO2·H2O), 18g / L, complexing agent sodium citrate 100g / L, ammonium sulfate 90g / L, respectively dissolved in deionized water, mixed to the specified The volume of the plating solution is adjusted to a pH value of 7.0 with ammonia water, and the aluminum drum is plated at a temperature of 70°C.

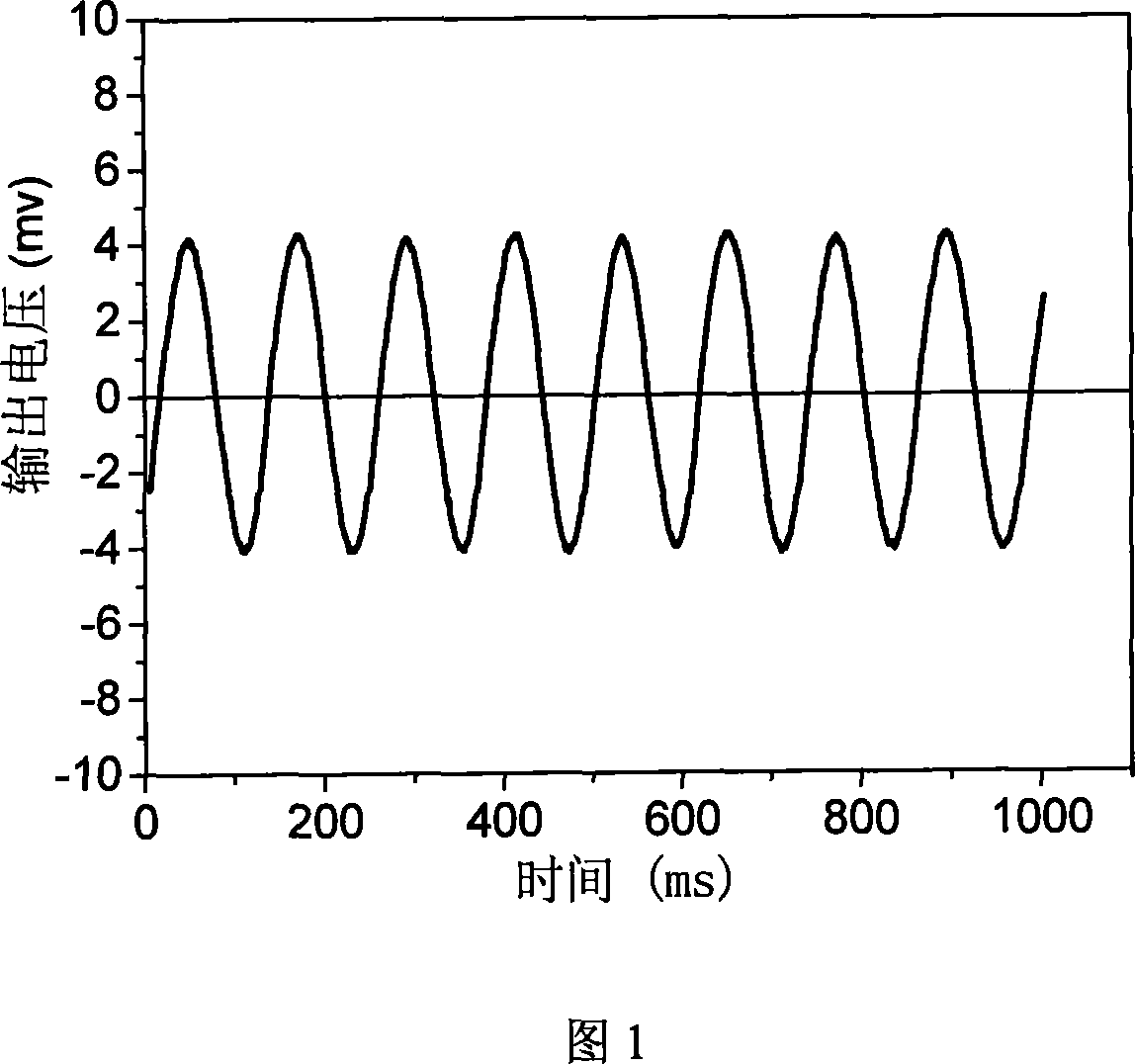

[0021] 4. Magnetization test: install the 4096PPR high-resolution optical encoder and the magnetic drum to be magnetized on the same shaft, and drive it to rotate at a constant spe...

Embodiment 2

[0023] 1. Aluminum drum cleaning

[0024] The cleaning steps are the same as in Example 1.

[0025] 2. Grinding and polishing the surface of the aluminum drum

[0026] With embodiment 1.

[0027] 3. Electroless plating of Co-Ni-P magnetic recording film: the main salt cobalt sulfate (CoSO 4 7H2O) 25g / L, nickel sulfate (NiSO4 7H2O) 20g / L, reducing agent sodium hypophosphite (NaH2PO2 H2O), 20g / L, complexing agent sodium citrate 110g / L, ammonium sulfate 100g / L, Dissolve in deionized water respectively, mix to the specified volume of the plating solution, adjust the pH value to 8.5 with ammonia water, and apply plating to the aluminum drum at a temperature of 80°C.

[0028] 4. Magnetization test

[0029] With embodiment 1.

Embodiment 3

[0031] 1. Aluminum drum cleaning

[0032] The cleaning steps are the same as in Example 1.

[0033] 2. Grinding and polishing the surface of the aluminum drum

[0034] With embodiment 1.

[0035] 3. Electroless plating Co-P magnetic recording film: the main salt cobalt sulfate (CoSO 4 7H2O) 30L, reducing agent sodium hypophosphite (NaH2PO2·H2O), 25g / L, complexing agent sodium citrate 12g / L, ammonium sulfate 105g / L, respectively dissolved in deionized water, mixed to the specified plating solution volume, adjust the pH value to 10.0 with ammonia water, and apply plating to the aluminum drum at a temperature of 80°C.

[0036] 4. Magnetization test

[0037] Same as embodiment 1, write 2048 pairs of magnetic poles to the magnetic drum at last.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com