Series of elliptical metal sulfide grain, its production and use

A metal sulfide, ellipsoid technology, used in the preparation of sulfide/polysulfide, chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of difficult to obtain uniform particles, difficult to control conditions, etc. Simple and easy, controllable size, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare zinc acetate aqueous solution, its molar concentration is 0.1mol / L; prepare sodium sulfide aqueous solution, its molar concentration is 0.2mol / L; prepare ammonia solution, its molar concentration is 10mol / L; prepare sodium hydroxide aqueous solution, its molar concentration 1.0mol / L. At 20°C, mix the configured zinc acetate aqueous solution, sodium sulfide aqueous solution, and ammonia aqueous solution in a molar ratio of 1:1:100, adjust the pH value of the reaction system to 13.5 with aqueous sodium hydroxide solution, stir, and age 4 hours; the sediment was washed, centrifuged, and dried to obtain ellipsoidal zinc sulfide particles with an average major axis size of 1.8 μm, an average minor axis size of 1.2 μm, and an average aspect ratio of 1.5. The ellipsoidal zinc sulfide particles can be used as fluorescent materials, electroluminescent materials, high-grade paints, laser materials, biological marker materials, photonic crystal assembly materials and the l...

Embodiment 2

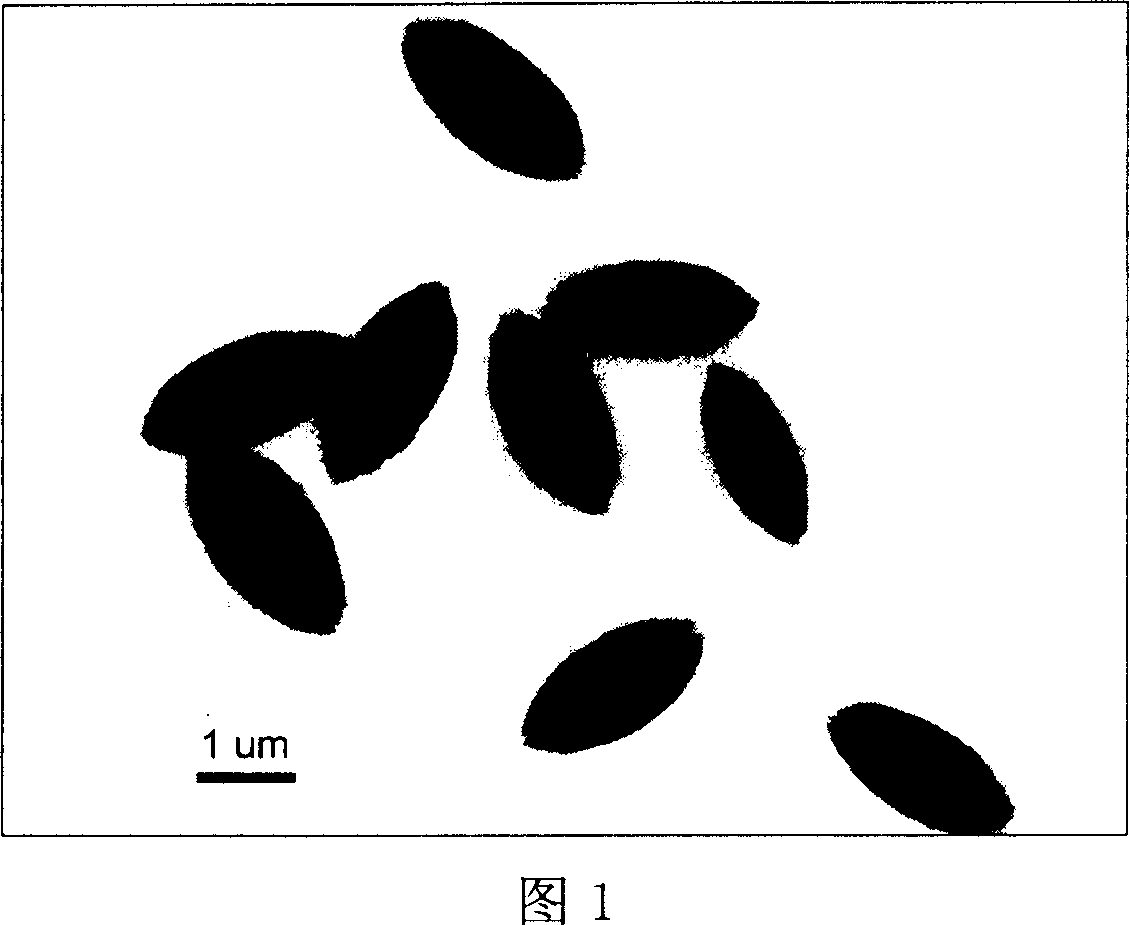

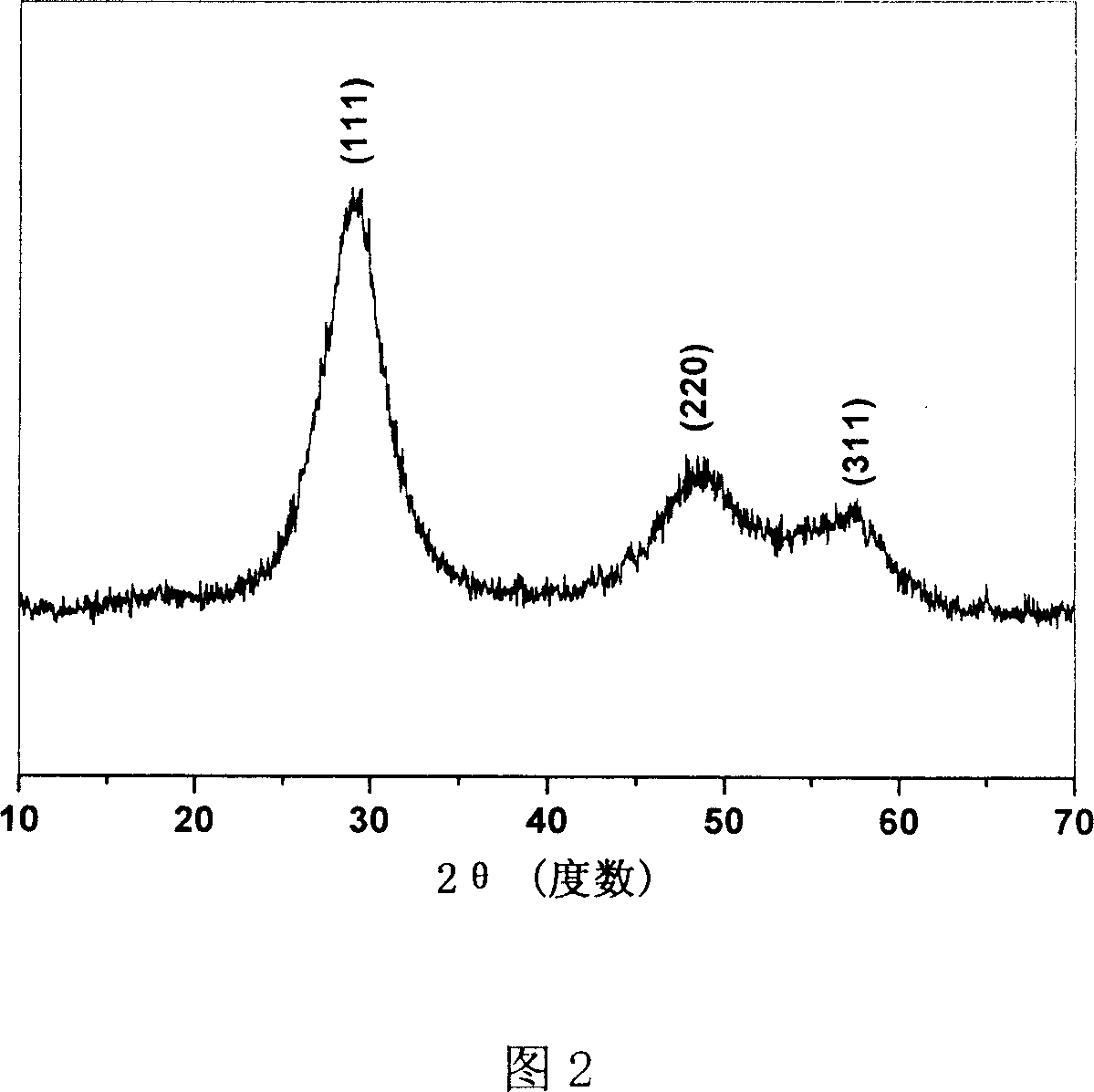

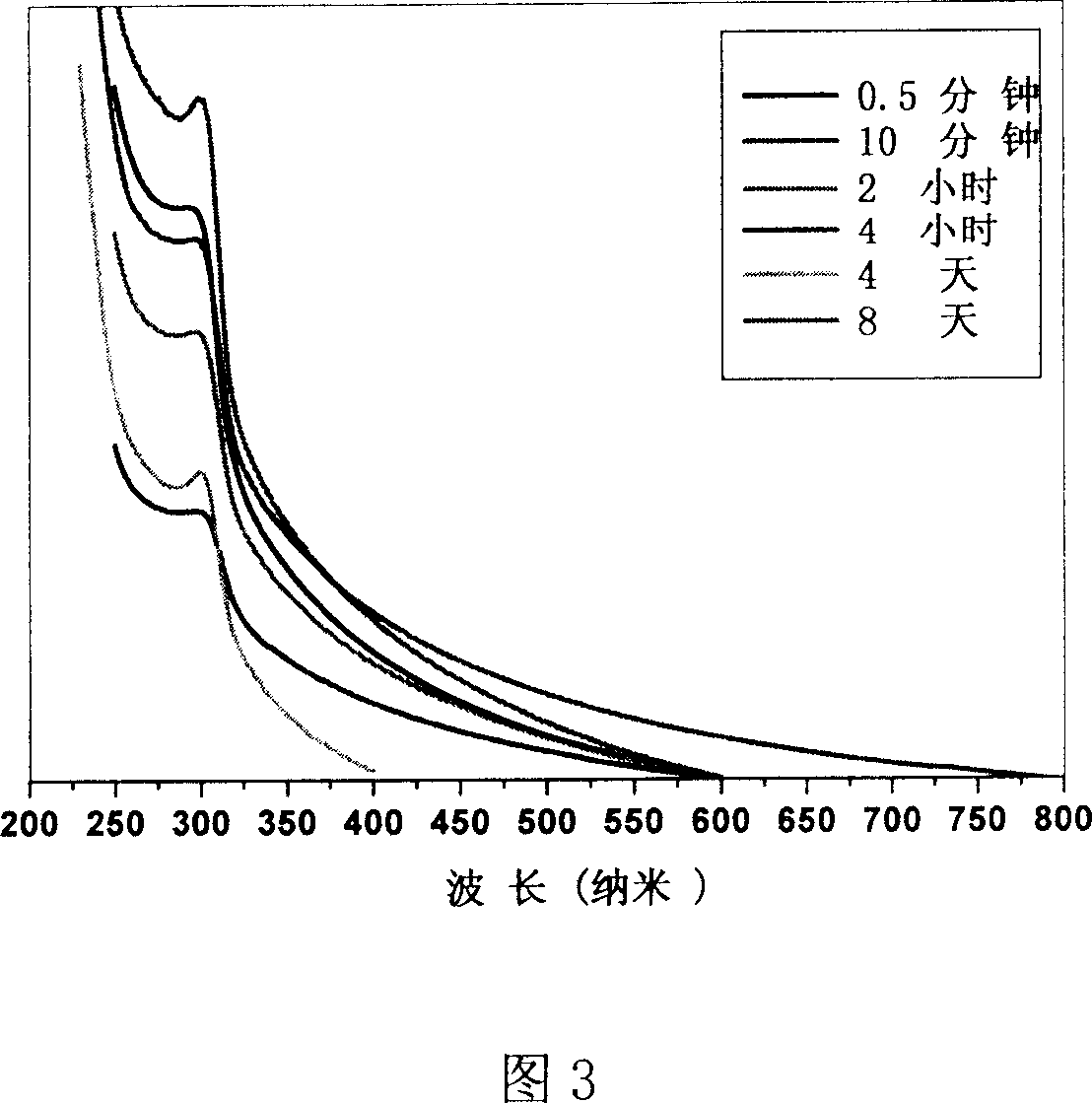

[0036]Prepare an aqueous zinc sulfate solution with a molar concentration of 0.5mol / L; prepare an aqueous ammonia sulfide solution with a molar concentration of 0.6mol / L; prepare an aqueous ammonia solution with a molar concentration of 3mol / L; prepare an aqueous sodium hydroxide solution with a molar concentration of It is 3.0mol / L. At 40°C, mix the configured zinc sulfate aqueous solution, ammonia sulfide aqueous solution, and ammonia aqueous solution in a molar ratio of 1:0.5:20, adjust the pH value of the reaction system to 12.5 with aqueous sodium hydroxide solution, stir, and age 24 hours; the precipitate was washed, centrifuged, and dried. The average size of the long axis of the obtained product was 3.5 μm, the average size of the short axis was 1 μm, and the average aspect ratio was 3.5. The ellipsoidal zinc sulfide particles, see the electron microscope photo Figure 1, the X-ray diffraction pattern of the product is shown in Figure 2, and the ultraviolet absorption s...

Embodiment 3

[0038] Prepare cadmium nitrate aqueous solution, its molar concentration is 5mol / L; Prepare potassium sulfide aqueous solution, its molar concentration is 0.6mol / L; Prepare ethylenediamine aqueous solution, its molar concentration is 0.5mol / L; Prepare potassium hydroxide aqueous solution, its The molar concentration is 5.0mol / L. At 10°C, mix the configured cadmium nitrate aqueous solution, potassium sulfide aqueous solution, and ethylenediamine aqueous solution in a molar ratio of 1:5:10, adjust the pH value of the reaction system to 10 with potassium hydroxide aqueous solution, and stir. Aging for 8 days; the precipitate was washed, centrifuged, and dried to obtain ellipsoidal cadmium sulfide particles with an average major axis size of 1 μm, an average minor axis size of 0.4 μm, and an average aspect ratio of 2.5. The ellipsoidal zinc sulfide particles can be used as fluorescent materials, high-grade paints, laser materials, biomarker materials, electroluminescence materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com