Production of micron-solid epoxy-resin microsphere containing surface active group

A technology of porous epoxy resin and active groups, which is applied in the field of preparation of micron-scale non-porous epoxy resin microspheres, can solve the problems of wide particle size distribution, limited application range, and porosity of phenolic resin-based microspheres, and achieve good Toughness, low cost, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

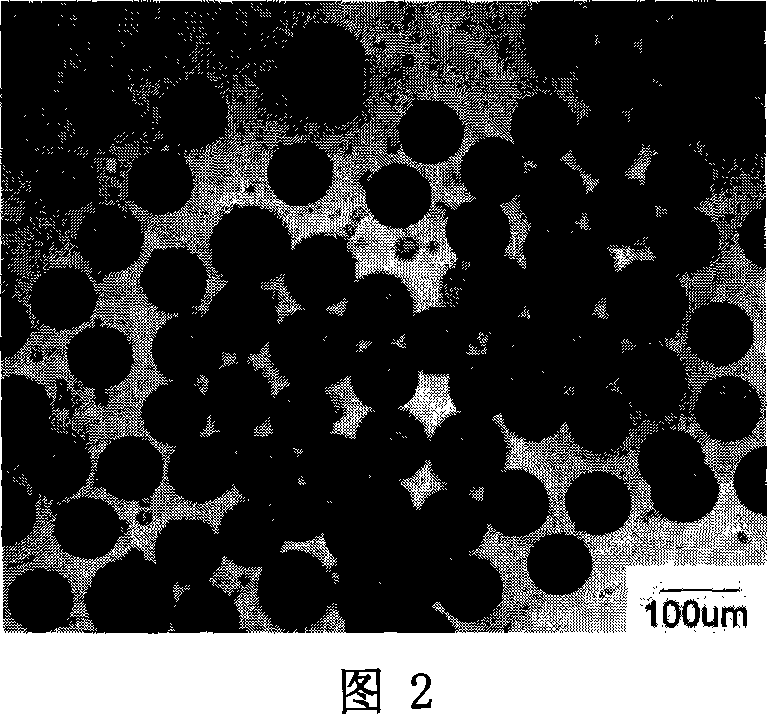

[0024] A preparation method of epoxy resin microspheres containing -OH groups on the surface: Add 0.8g gum arabic, 0.4g sodium dodecylbenzene sulfonate and 80ml deionized water into a 250ml three-necked reaction flask, and stir to make it fully Dissolve. Under stirring conditions, 10 g of bisphenol A epoxy resin E51, 10 g of propylene oxide butyl ether and 1.6 g of modified liquid imidazole JH-0512 are mixed uniformly to obtain an oil phase system. Then the oil phase system was added to a three-necked flask, stirred and emulsified for 20 minutes, slowly heated to a temperature between 80-85°C, and reacted at a constant temperature for 4 hours. After the reaction, the heating was stopped and allowed to cool to room temperature naturally. The product is filtered and dried to obtain the initial product. The initial product was post-cured at 150° C. for 1 hour to obtain epoxy resin microspheres with a synthesis yield of 95%.

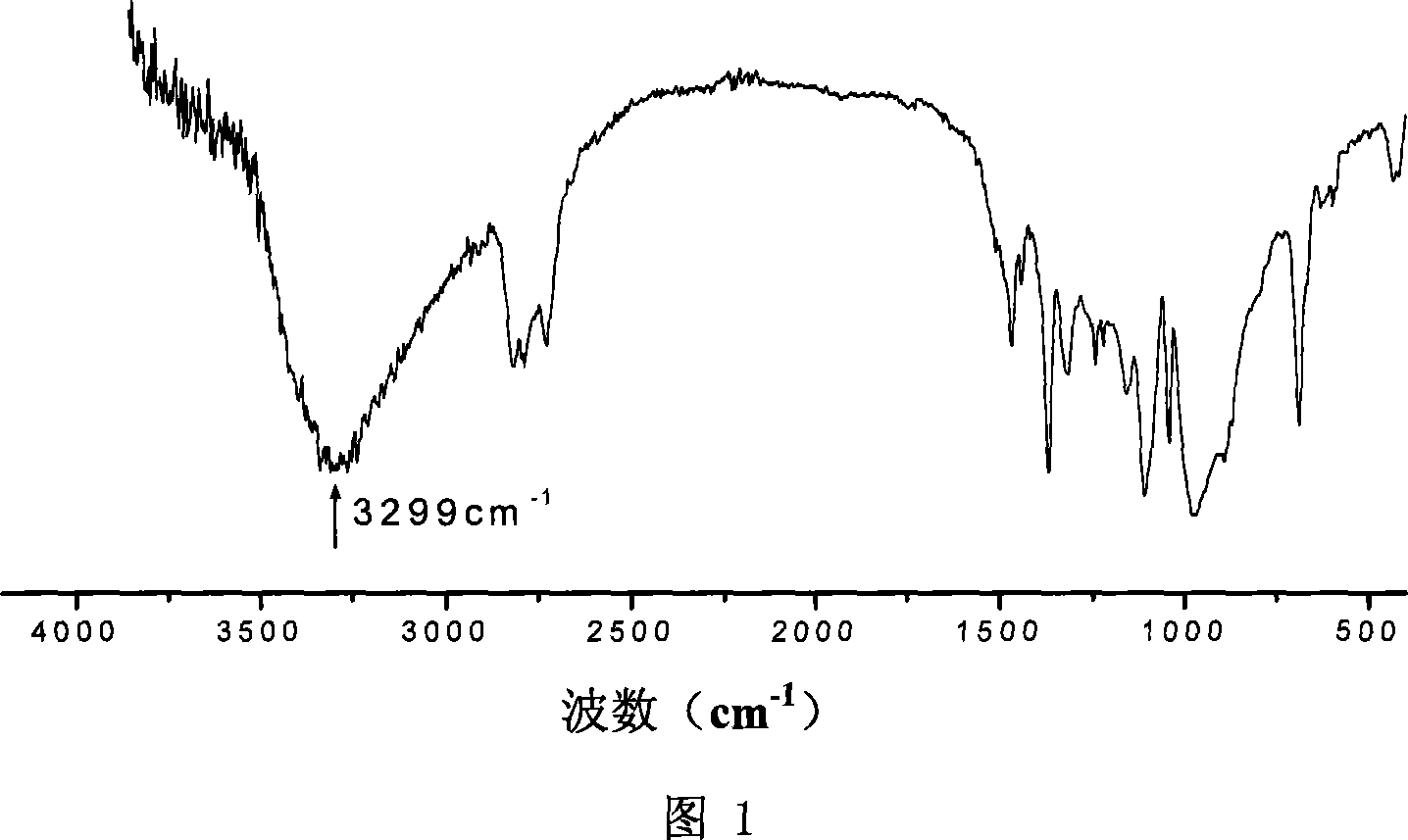

[0025] Referring to Figure 1, the epoxy resin microsphere ...

Embodiment 2

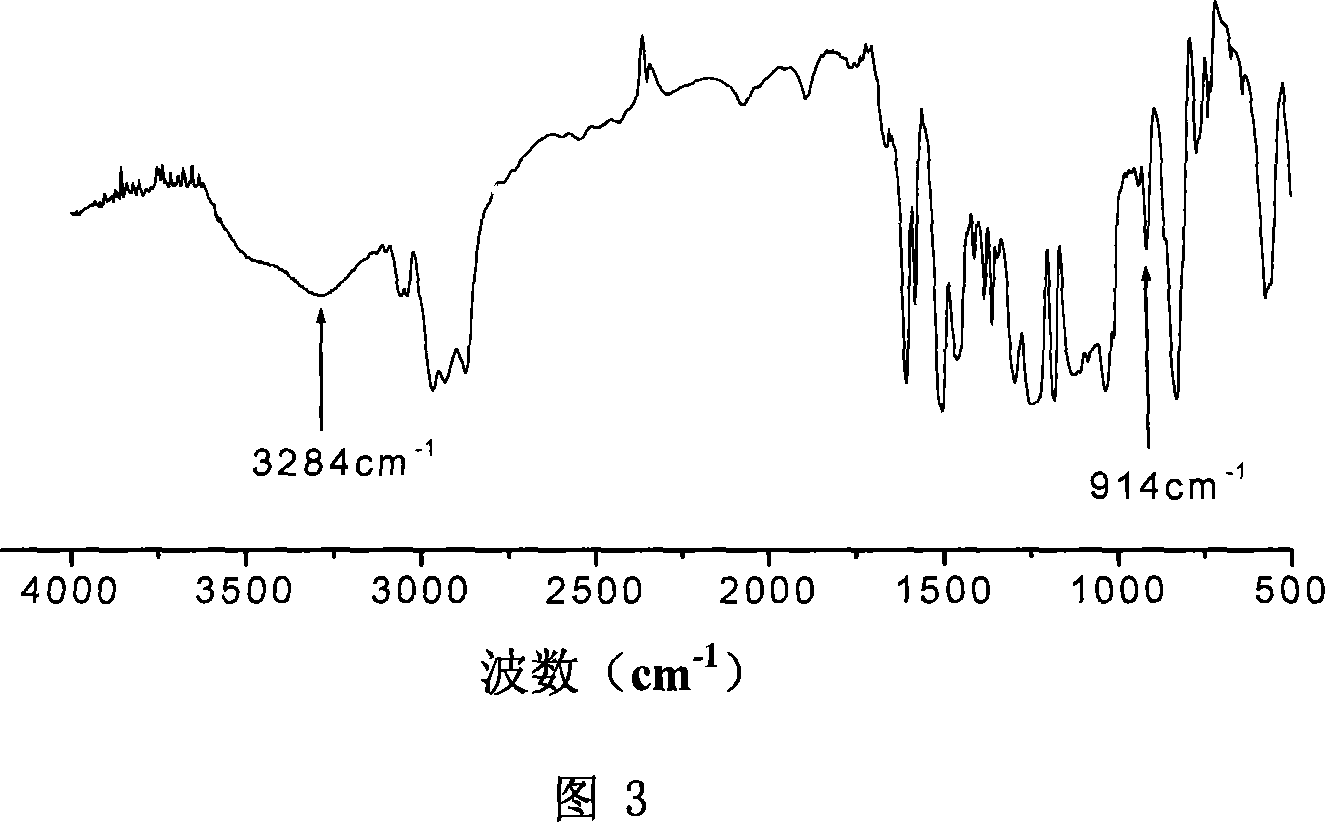

[0028] A preparation method of epoxy resin microspheres containing -OH groups on the surface: adding 1 g of gum arabic and 100 ml of deionized water into a 250 ml three-necked reaction flask, and stirring to make them fully dissolved. Under stirring conditions, mix 5g of bisphenol A epoxy resin E51, 5g of alicyclic epoxy resin TDE-85, 10g of propylene oxide butyl ether and 1.6g of 2-ethyl-4-methylimidazole. An oil phase system is obtained. Then the oil phase system was added to a three-necked flask, stirred and emulsified for 30 minutes, slowly heated to a temperature between 80-85°C, and reacted at a constant temperature for 5 hours. After the reaction, the heating was stopped and allowed to cool to room temperature naturally. The product is filtered and dried to obtain the initial product, which is post-cured at 100° C. for 3 hours to obtain epoxy resin microspheres. Its IR spectrum is at 3300cm -1 There are absorption peaks on the left and right, indicating that the prepared ep...

Embodiment 3

[0030] A preparation method of epoxy resin microspheres containing -OH groups on the surface: 0.375g gum arabic, 0.8g sodium dodecylbenzene sulfonate, 0.2g polyethylene glycol and 70ml deionized water were added to a 250ml three-necked reaction flask , Stir to fully dissolve. Under stirring conditions, 10 g of bisphenol A type epoxy resin E51, 8 g of bifunctional epoxy resin active diluent 6690 and 2 g of 2-ethyl-4-methylimidazole are mixed uniformly to obtain an oil phase system. Then the oil phase system was added to a three-necked flask, stirred and emulsified for 10 minutes, slowly heated to a temperature between 80-85°C, and reacted at a constant temperature for 3.5 hours. After the reaction, the heating was stopped and allowed to cool to room temperature naturally. The product is filtered and dried to obtain the initial product, which is post-cured at 120° C. for 2 hours to obtain epoxy resin microspheres. Its IR spectrum is at 3300cm -1 There are absorption peaks on the lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com