Method for preparing zirconium oxide coating on magnesium alloy surface

A magnesium alloy, zirconia technology, applied in anodizing, electrolytic inorganic material coating and other directions, can solve the problems of complex zirconia coating equipment, weak matrix bonding, thermal influence of the matrix, etc., to achieve excellent thermal and mechanical properties, high Strength, the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

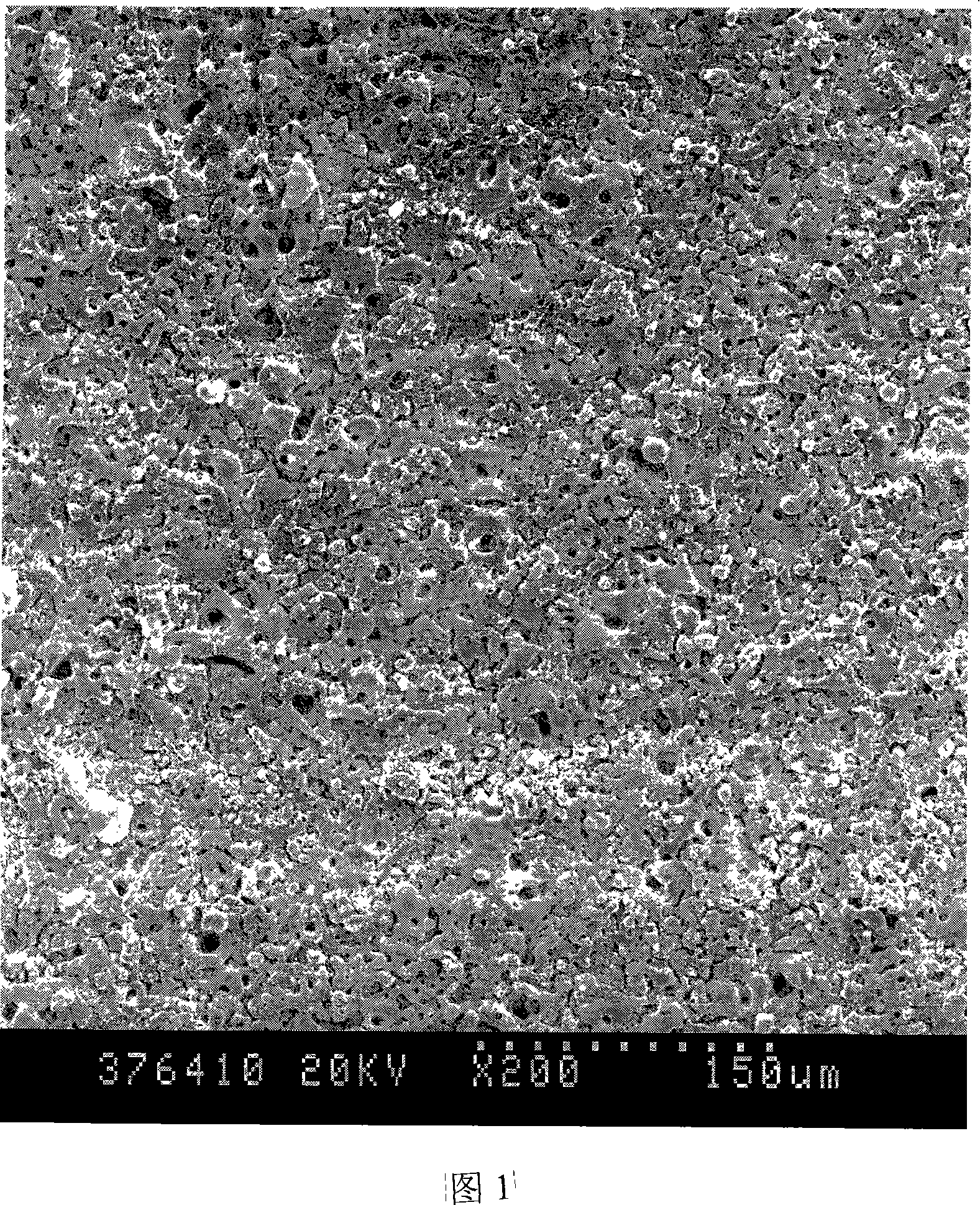

Image

Examples

specific Embodiment approach 1

[0009] Embodiment 1: The steps of the method for preparing a zirconia coating on the surface of a magnesium alloy in this embodiment are as follows: 1. Electrolyte preparation: first dissolve phosphoric acid and / or phosphate in distilled water, and then add potassium hexafluorozirconate while stirring 1-10g of potassium hexafluorozirconate, 0.5-10ml of phosphoric acid and / or 0.5-6g of phosphate are added to each liter of electrolyte; 2. Polish the magnesium alloy smooth and then wash it with water; The magnesium alloy is placed in the electrolyte as the positive electrode, and the stainless steel plate is used as the negative electrode. The control range of the temperature of the electrolyte is between 10 and 40°C. The micro-arc oxidation power supply is used for power supply. The peak voltage range of the micro-arc oxidation power supply is 300-700V. Both the positive and negative phase current densities are 200~900A / M 2 , the power frequency is 60-2000Hz, and the reaction is...

specific Embodiment approach 2

[0012] Specific embodiment two: In this embodiment, in step one, the phosphate is one or more of sodium dihydrogen phosphate, potassium dihydrogen phosphate, and sodium polyphosphate. Others are the same as in the first embodiment.

[0013] When the phosphate is a mixture of sodium dihydrogen phosphate, potassium dihydrogen phosphate and sodium polyphosphate, mix them in any ratio.

specific Embodiment approach 3

[0014] Embodiment 3: In this embodiment, 2-5 g of potassium hexafluorozirconate is added to each liter of electrolyte solution in step 1. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com