Microwave source cathode and manufacturing method therefor

A microwave source and cathode technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of affecting the output efficiency of the microwave source, the influence should not be too large, and the gas emission is not uniform. Achieving the effect of excellent emission and electron beam current characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

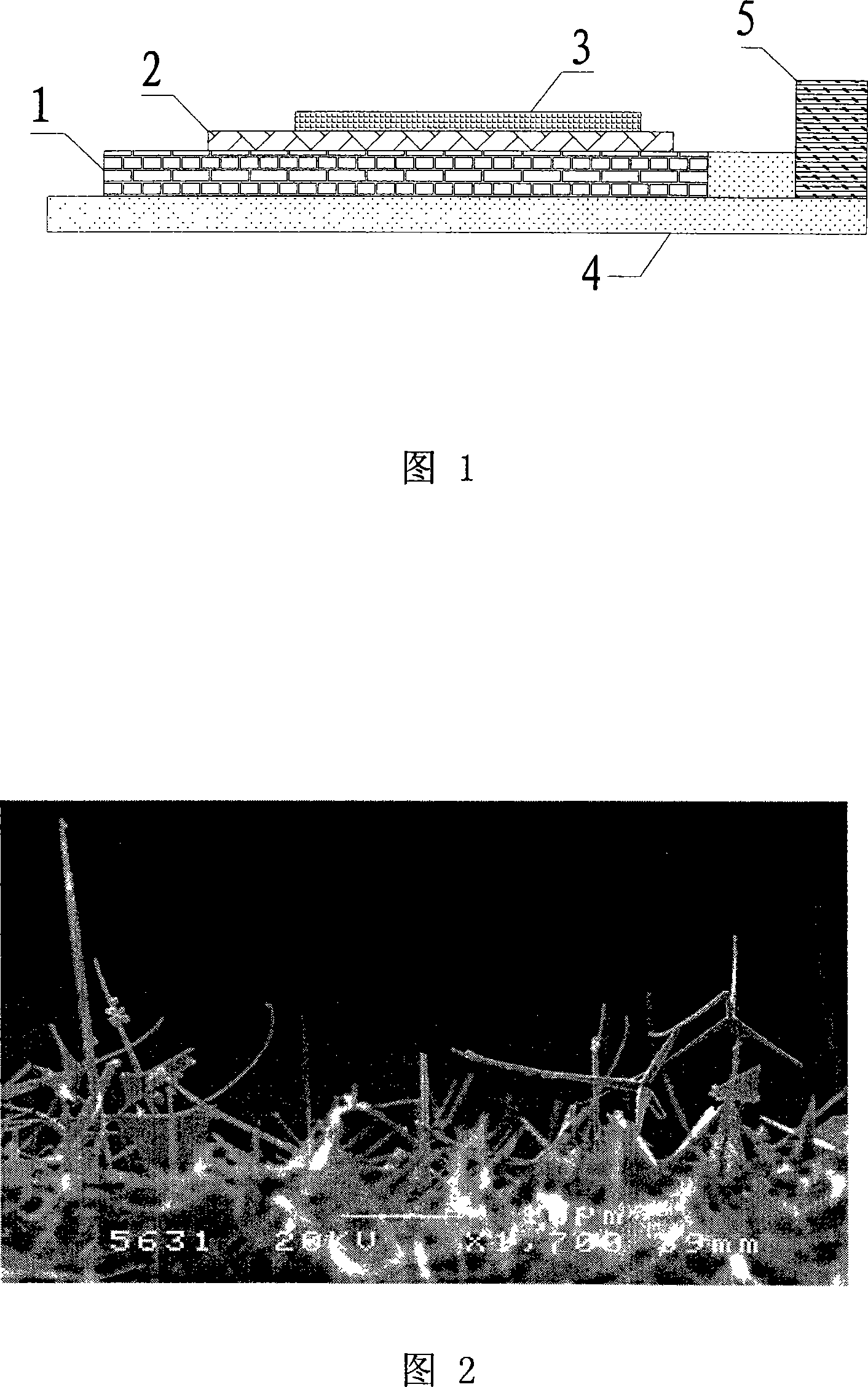

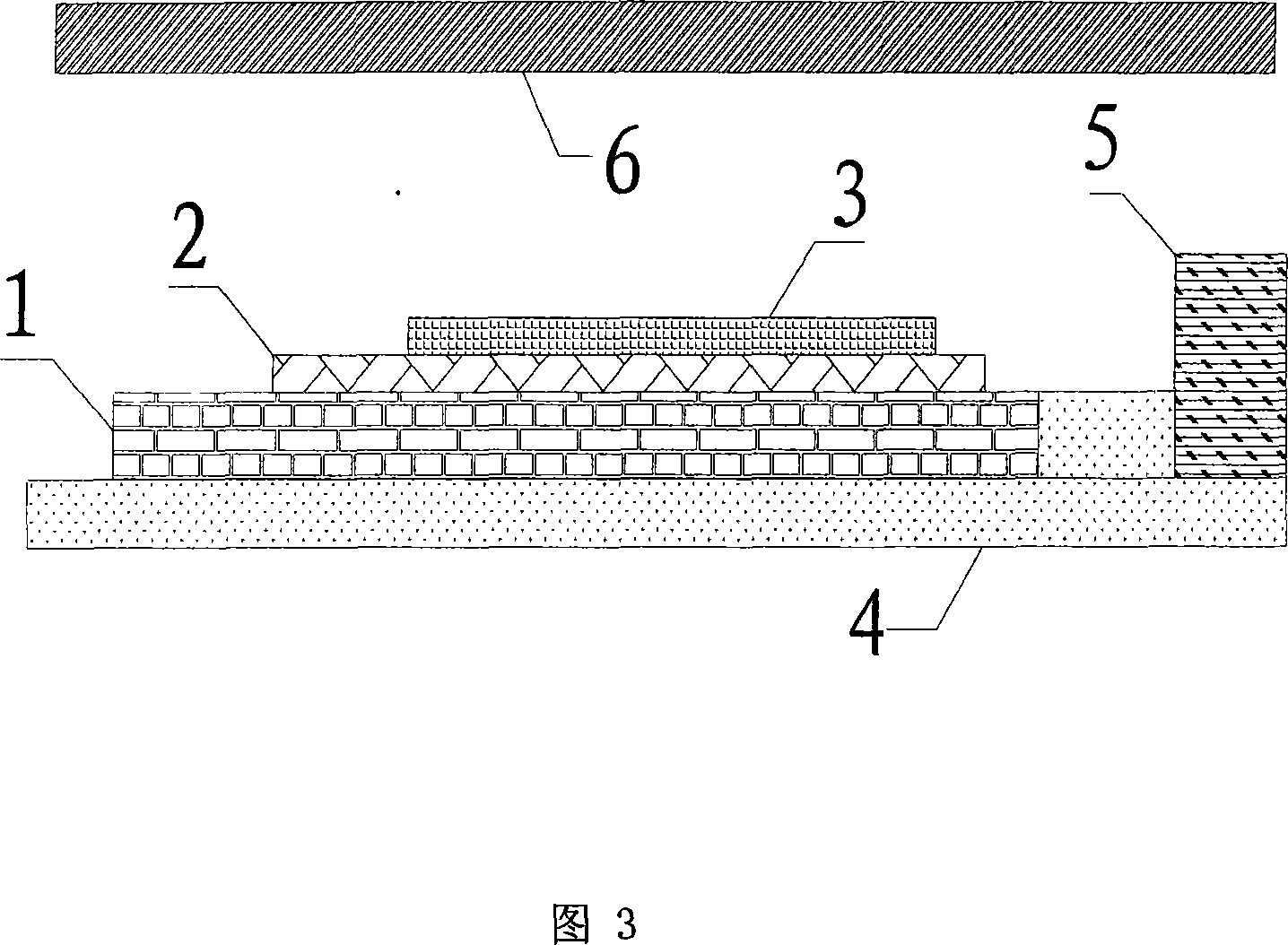

[0027] Embodiment 1: microwave source negative electrode and manufacturing method thereof comprise the following steps: step 1, after mixing 10 grams of four-needle nano-zinc oxide and 100 grams of terpineol in water at 90 degrees Celsius, add an appropriate amount of ethyl cellulose to thicken, and then add 1.1 grams of carbon nanotubes and 2.2 grams of magnesium oxide powder are fully stirred to obtain a slurry; step 2, the slurry in step 1 is printed on the polyacrylonitrile-based activated carbon fiber by screen printing, and the thickness of the slurry is 40 microns; Step 3, as shown in Figure 2 at 10 -2 After the polyacrylonitrile-based activated carbon fiber in step 2 was baked at a high temperature of 350 degrees Celsius for 3 hours in Pa vacuum, the organic matter in the slurry was decomposed and volatilized, and the method of plasma etching was used to activate the polyacrylonitrile-based activated carbon fiber. Carry out hydrophilic treatment on the carbon fiber sur...

Embodiment 2

[0028] Embodiment 2: microwave source negative electrode and manufacturing method thereof comprise the following steps: Step 1, after mixing 10 grams of four-needle nano-zinc oxide with 1000 grams of terpineol in water at 90 degrees Celsius, add an appropriate amount of ethyl cellulose to thicken, and then add 10.1 grams of carbon nanotubes and 20.2 grams of magnesium oxide powder are fully stirred to obtain a slurry; step 2, the slurry in step 1 is printed on the polyacrylonitrile-based activated carbon fiber by screen printing, and the thickness of the slurry is 400 microns; Step 3, as shown in Figure 2 at 10 -2 After the polyacrylonitrile-based activated carbon fiber in step 2 was baked at a high temperature of 350 degrees Celsius for 3 hours in Pa vacuum, the organic matter in the slurry was decomposed and volatilized, and the method of plasma etching was used to activate the polyacrylonitrile-based activated carbon fiber. Carry out hydrophilic treatment on the carbon fibe...

Embodiment 3

[0029] Embodiment three: microwave source negative electrode and manufacturing method thereof comprise the following steps: Step 1, after mixing 10 grams of four-needle nano zinc oxide and 500 grams of terpineol in water at 90 degrees Celsius, add an appropriate amount of ethyl cellulose to thicken, and then add 5.1 grams of carbon nanotubes and 10.2 grams of magnesium oxide powder are fully stirred to obtain a slurry; step 2, the slurry in step 1 is printed on polyacrylonitrile-based activated carbon fibers by screen printing, and the thickness of the slurry is 200 microns; Step 3, as shown in Figure 2 at 10 -2 After the polyacrylonitrile-based activated carbon fiber in step 2 was baked at a high temperature of 350 degrees Celsius for 3 hours in Pa vacuum, the organic matter in the slurry was decomposed and volatilized, and the method of plasma etching was used to activate the polyacrylonitrile-based activated carbon fiber. Carry out hydrophilic treatment on the carbon fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com