Block polyether compound modified lignin and preparation method and uses thereof

A technology of block polyether and lignin, applied in the directions of lignin derivatives, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficulties, and achieve the effects of improving utilization rate, reducing consumption and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

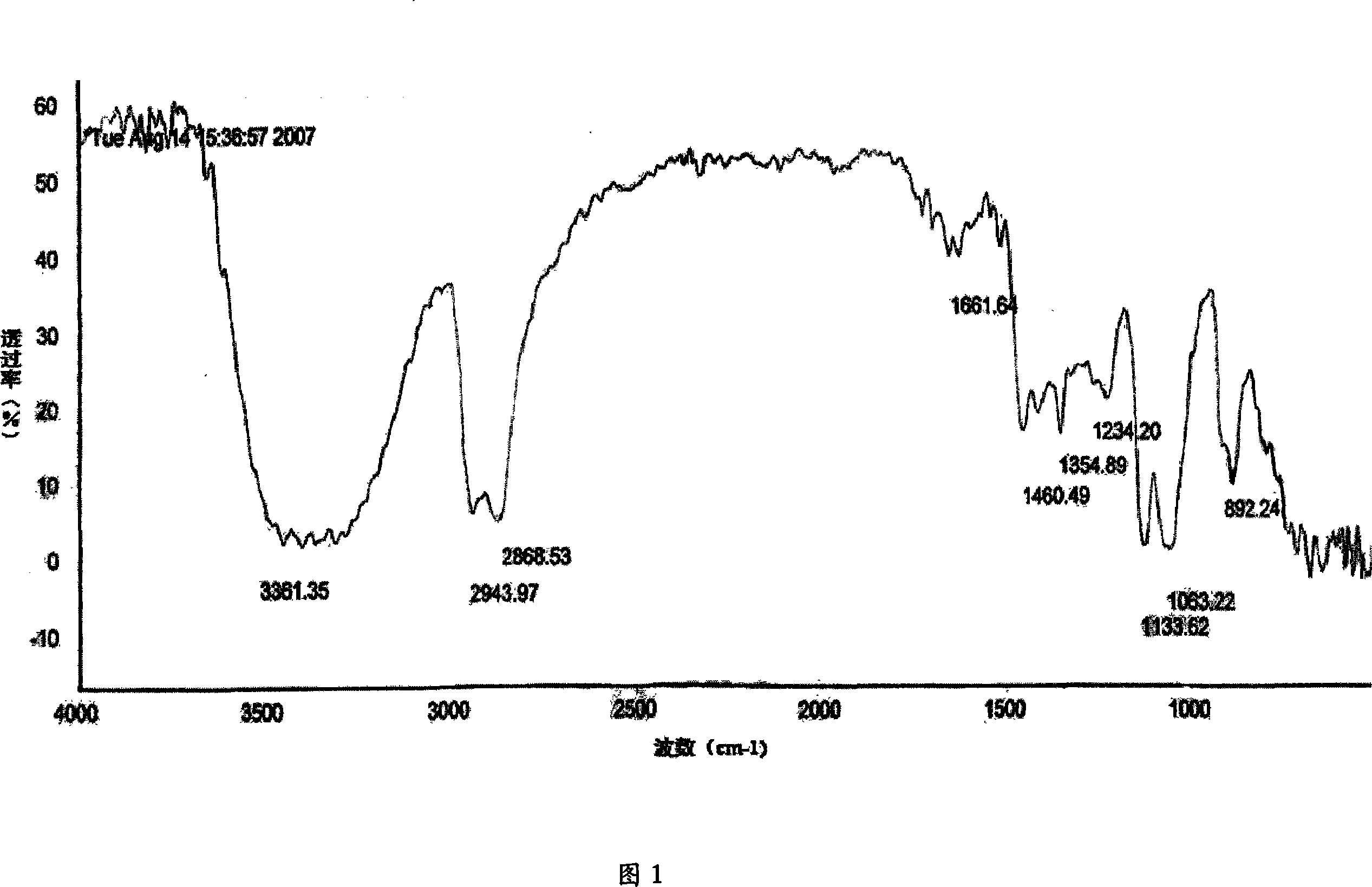

Image

Examples

Embodiment 1

[0027] Separation and purification of lignin:

[0028] Take 100 parts by mass of crude alkali lignin, make it into a 10% mass fraction aqueous solution, adjust the pH of the solution to 12 with 10% mass fraction of NaOH, until all the lignin is dissolved, and centrifuge at 6000r / rain for 5min to remove insoluble impurities Afterwards, the solution was heated to 60°C, adjusted to pH 3 with 20% mass fraction of sulfuric acid, left to stand, the supernatant was removed, the precipitate was washed with water, centrifuged at 6000r / rain for 10min, the precipitate was washed to neutral, and the precipitate was washed at 105 After drying at ℃, it was ground into powder, and 70 parts by mass of purified lignin was obtained by weighing, which was sealed and stored for future use. The chemical composition of the obtained purified lignin is as follows: the mass fraction of lignin is 95%, the mass fraction of total sugar is 2.70%, the mass fraction of ash is 1.70%, and the molar concentrat...

Embodiment 2

[0030] Purification of lignosulfonate

[0031] Take 100 parts by mass of crude lignosulfonate, make it into an aqueous solution with a mass fraction of 50%, add 8 mass fractions of sulfur, stir and react at 230°C for 30min, stop heating, quickly cool the reactant to room temperature, add 30 mass fractions of sulfur Dilute with water, add 2 mass fractions of 10% sulfuric acid, acidify for 10 minutes, add 50 mass fractions of ethyl acetate for extraction, stop stirring, let stand to separate layers, take the upper organic phase, evaporate the ethyl acetate solvent, and extract the remaining solid The product was vacuum-dried at room temperature 1KPa for 10 hr, the dried purified lignin was ground into powder, and 80 parts by mass of purified lignin were obtained by weighing, which was sealed and stored for future use. The chemical composition of the obtained purified lignin is as follows: the mass fraction of lignin is 98%, the mass fraction of ash is 1.70%, and the mass molar c...

Embodiment 3

[0033] The preparation method of block polyether compound modified lignin:

[0034] A. Before adding raw materials, the pressure-resistant reactor is evacuated to a vacuum degree of 2-4KPa, filled with nitrogen to normal pressure, and repeated 2-3 times to remove the oxygen in the pressure-resistant reactor;

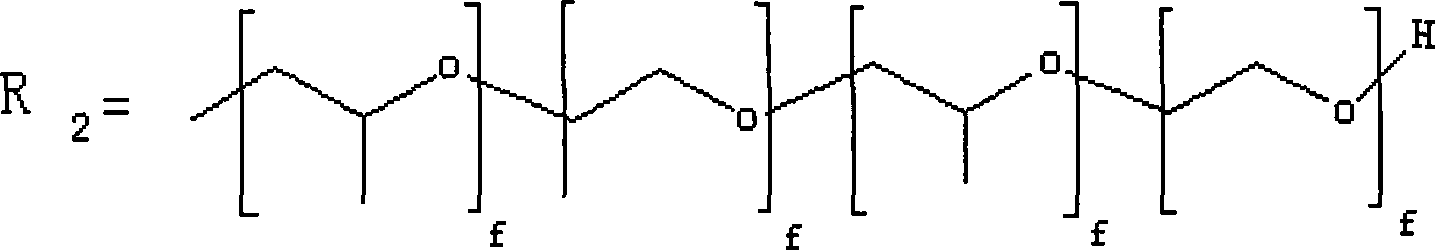

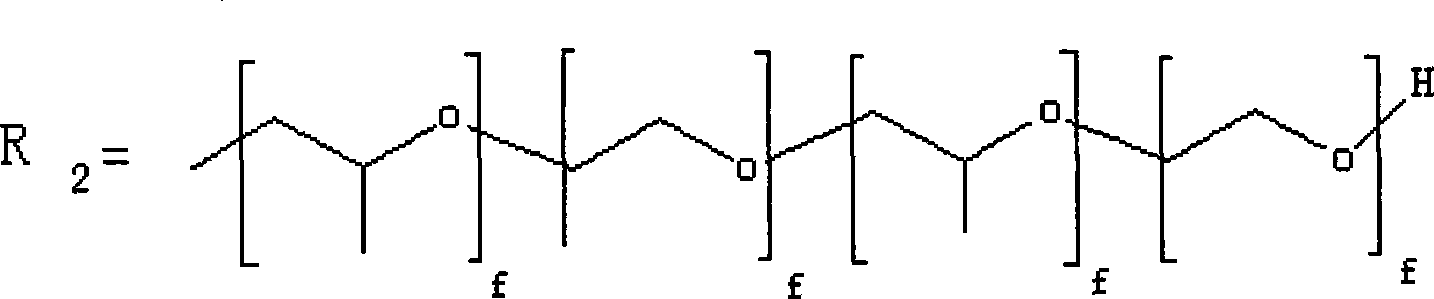

[0035] B. Take 100 parts by mass of purified lignin, 0.5 to 3 parts by mass of alkali catalyst, and 30 to 80 parts by mass of aromatic hydrocarbon solvent, and put them into a pressure-resistant reactor; after feeding, feed nitrogen protection, seal the pressure-resistant reactor and stir, and heat up To 90-120°C, when the reaction pressure is 0.3-1.0MPa, divide 30-80 mass parts of ethylene oxide and 30-80 mass parts of propylene oxide into 4-8 groups;

[0036] C. After passing in one group of ethylene oxide each time and reacting for 30-60 minutes, then passing in one group of propylene oxide for 30-60 minutes;

[0037] D. Repeat step C until all ethylene oxide and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com