Mutagenesis breeding method for high-fat dunaliella salina

A technology of Dunaliella liposum and Dunaliella, which is applied in the field of Dunaliella, and can solve problems such as the absence of high-fat Dunaliella

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

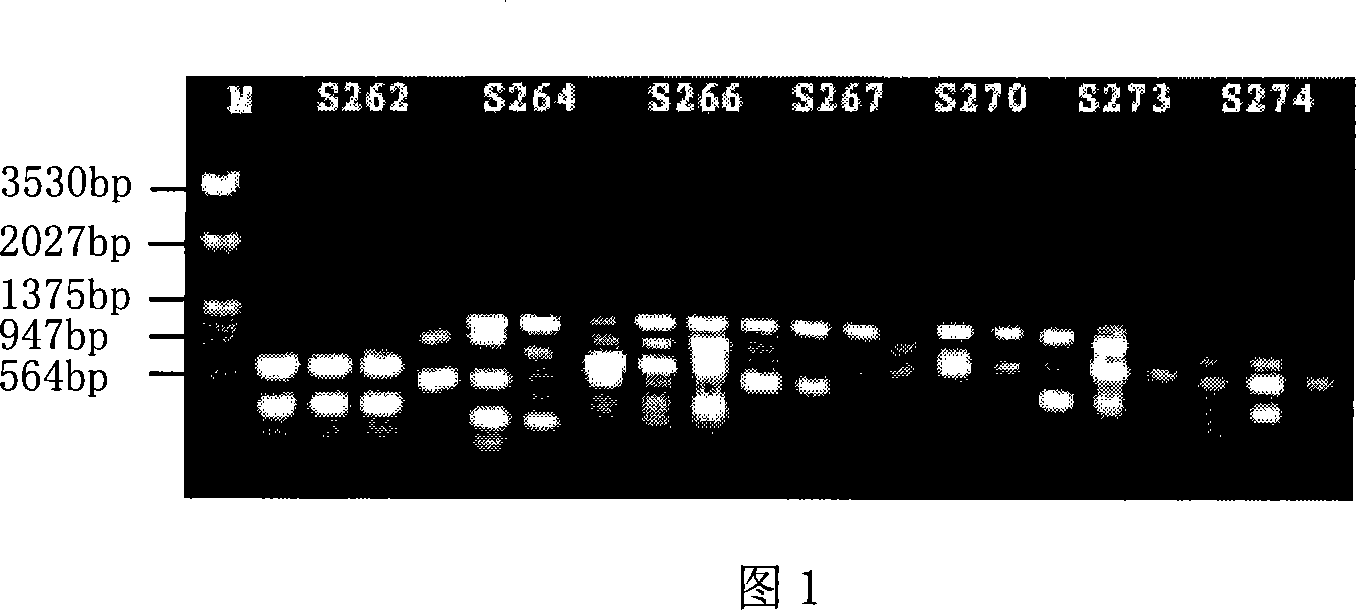

Image

Examples

Embodiment 1

[0053] The specific steps for the ultraviolet mutagenesis of Dunaliella and the breeding of Dunaliella with high lipids are as follows:

[0054] 1. Prepare artificial seawater culture solution for cultivating Dunaliella;

[0055] 2. Divide the above-mentioned artificial seawater culture solution into 100mL Erlenmeyer flasks, each with a volume of 20mL, plug it tightly with a cotton plug, and wrap it with kraft paper;

[0056] 3. Place the packaged above-mentioned culture solution in an autoclave, and sterilize at 121°C and a pressure of 0.1mPa for 15 minutes;

[0057] 4. Take out the sterilized culture medium, cool it to room temperature, inoculate 1mL Dunaliella algae liquid, shake it gently, and plug it with a cotton plug;

[0058] 5. Place the culture medium in a light incubator with a light intensity of 8000 lux, a culture temperature of 28°C, a daily light of 24 hours, and rotate and shake at 90 rpm;

[0059] 6. Take out 3.5mL of algae liquid every day, use the artifici...

Embodiment 2

[0071] Similar to Example 1, the difference is:

[0072] The artificial seawater culture solution was divided into 250mL Erlenmeyer flasks, each containing 50mL, sealed with 8 layers of gauze, and wrapped with kraft paper. Place the packaged above-mentioned culture solution in an autoclave, and sterilize at 121° C. and a pressure of 0.1 mPa for 20 minutes. Take out the sterilized culture medium, cool it down to room temperature, inoculate 5mL Dunaliella algae liquid into the sterile medium, shake it gently, and seal it with gauze. Place the culture solution in a light incubator with a light intensity of 10,000 lux, a culture temperature of 30°C, and light for 24 hours a day, for static culture, and gently shake 1 to 3 times a day for 10 to 20 seconds each time.

[0073] Dunaliella in exponential growth phase (OD 630 Value is 0.545), evenly spread on the agar medium (the NaCl concentration of the used Dunaliella agar medium is increased to 2.5mol / L, and each plate is coated w...

Embodiment 3

[0082] Similar to Example 1, the difference is:

[0083] The artificial seawater culture solution was divided into 200mL Erlenmeyer flasks, each containing 40mL, sealed with cotton plugs, and wrapped with kraft paper. Place the packaged above-mentioned culture solution in an autoclave, and sterilize at 121° C. and a pressure of 0.1 mPa for 15 minutes. Take out the sterilized culture medium, after cooling to room temperature, inoculate 3 mL of Dunaliella algae liquid into the sterile culture medium, shake it gently, and plug it with a cotton plug. The culture solution was placed in a light incubator with a light intensity of 15000 lux, a culture temperature of 25°C, 12 hours of light per day and 12 hours of darkness, static culture, and gently shaking 1-3 times a day, 10-20s each time.

[0084] Dunaliella algae liquid (OD 630 The value is 0.485) 1mL, injected directly into the sterile plate. Place the plate at 13cm under a 30W ultraviolet lamp in an ultra-clean workbench, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com