Integrated device for preparing hydrogen by the recapitalization of dimethyl ether aqueous vapor and method

A technology of steam reforming and hydrogen production equipment, which is applied in the direction of chemical instruments and methods, hydrogen, bulk chemical production, etc. It can solve the problems of complex gas components, high energy consumption, and difficulty in obtaining hydrogen, so as to improve the reaction Effects of conversion rate and hydrogen yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

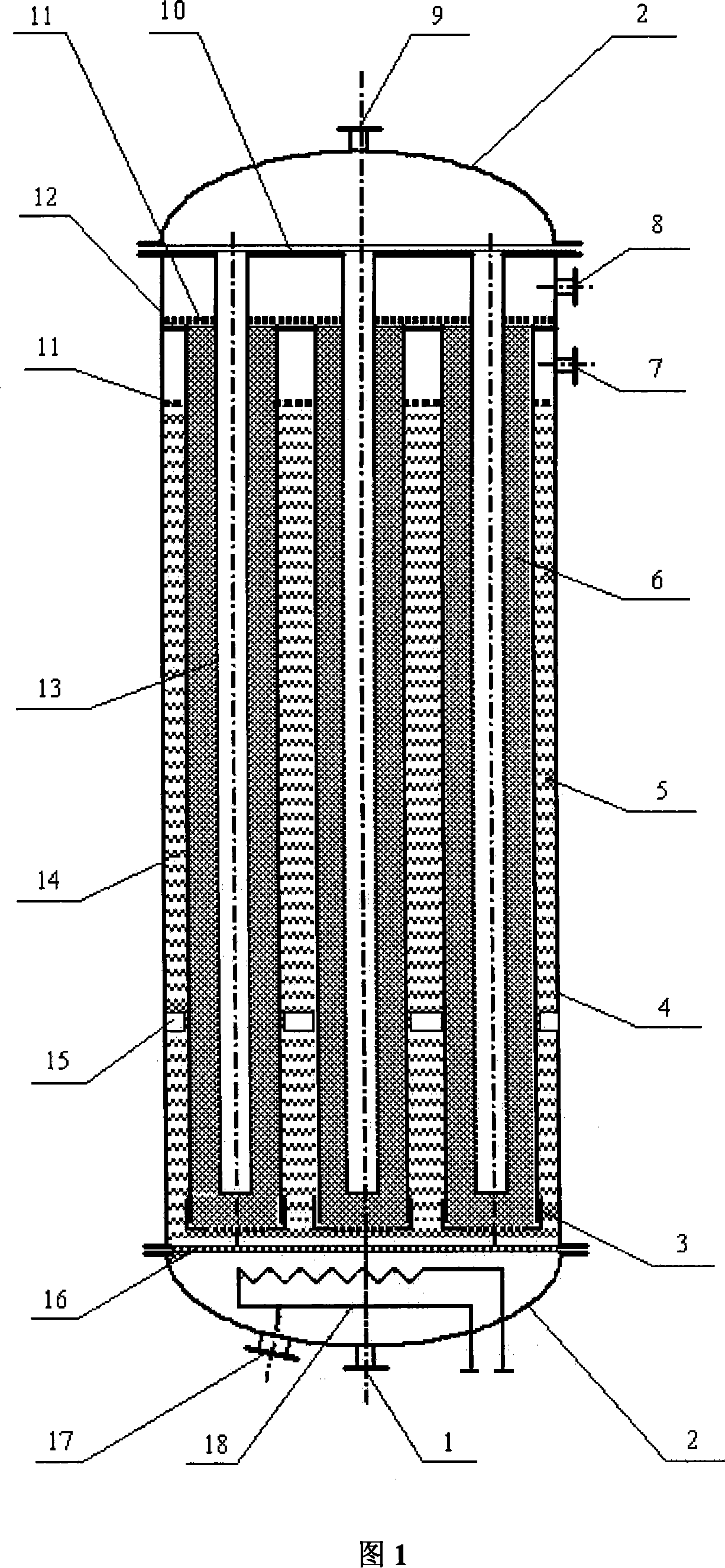

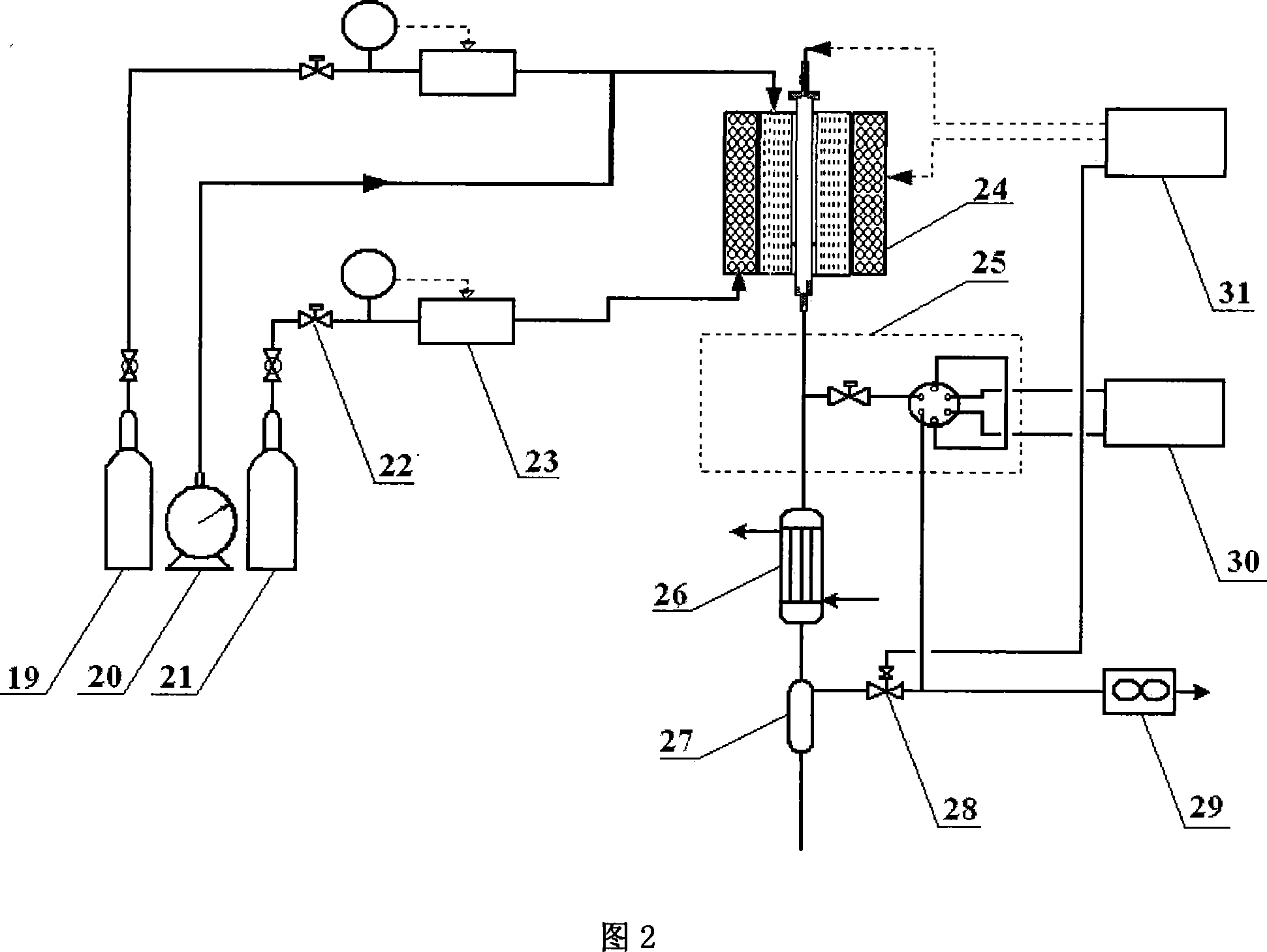

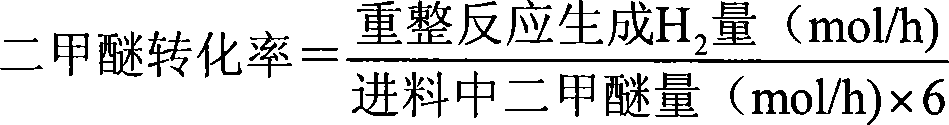

[0036] 0.02m 3 / h Dimethyl ether hydrogen production unit

[0037] The reaction device is constructed as shown in Figure 2. The membrane reactor is used, the reaction temperature is 200°C, the reaction pressure is 0.1MPa, the center tube is made of palladium-silver alloy, the mass percentage of palladium and silver is 3:1, and the pressure in the center tube is normal pressure. The feed amount of ether is 500ml / min, the molar ratio of water to dimethyl ether is 3:1; the reforming catalyst adopts a mixture of molecular sieve ZSM-5 and copper-based catalyst, totaling 10g, and the ratio of molecular sieve catalyst ZSM-5 and copper-based catalyst is 10g. The weight ratio is 1:1, and the combustion-supporting catalyst adopts Pd / Al 2 O 3 Noble metal catalyst 5g, center tube assembly tube length 300mm, tube diameter 10mm, film thickness 0.06mm, 5 center tubes, the conversion rate of dimethyl ether is 60%, and the scale of hydrogen production is 0.02m 3 / h, the hydrogen recovery rate is 8...

Embodiment 2

[0039] 0.03m 3 / h Dimethyl ether hydrogen production unit

[0040] The reaction device is constructed as shown in Figure 2. The membrane reactor of Example 1 is used, the reaction temperature is 300°C, the reaction pressure is 0.1MPa, the center tube is made of palladium-silver alloy, and the mass percentage of palladium and silver is 9:1. The pressure in the center tube is normal pressure. , The feed rate of dimethyl ether is 500ml / min, the molar ratio of water to dimethyl ether is 3:1, the reforming catalyst adopts a mixture of molecular sieve catalyst ZSM-5 and copper-based catalyst totaling 10g, molecular sieve ZSM-5 and copper The weight ratio of the base catalyst is 2:1, and the combustion-supporting catalyst adopts Pd / Al 2 O 3 Noble metal catalyst 5g, center tube assembly tube length 300mm, tube diameter 10mm, film thickness 0.06mm, 5 center tubes, the conversion rate of dimethyl ether obtained is 80%, and the scale of hydrogen production is 0.03m 3 / h, the hydrogen recover...

Embodiment 3

[0042] 0.3m 3 / h Dimethyl ether hydrogen production unit

[0043] The reaction device is constructed as shown in Figure 2. The membrane reactor of Example 1 is used, the reaction temperature is 300°C, the reaction pressure is 0.5MPa, the center tube uses a composite palladium membrane, the pressure in the center tube is normal pressure, and the feed volume of dimethyl ether is 5000ml / min, the molar ratio of water to dimethyl ether is 6:1, the catalyst is solid acid Al 2 O 3 100g of mixture with precious metal platinum catalyst, solid acid Al 2 O 3 The weight ratio to the precious metal platinum catalyst is 5:1, and the combustion-supporting catalyst adopts Pd / Al 2 O 3 Noble metal catalyst 50g, central tube assembly tube length 300mm, tube diameter 20mm, film thickness 0.01mm, 15 central tubes, the conversion rate of dimethyl ether obtained is 80%, and the hydrogen production scale is 0.3m 3 / h, the hydrogen recovery rate is 83%, the hydrogen purity is 99.5%, and the system therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com